Solution annealing of Stainless Steel

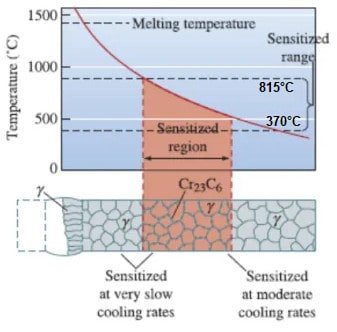

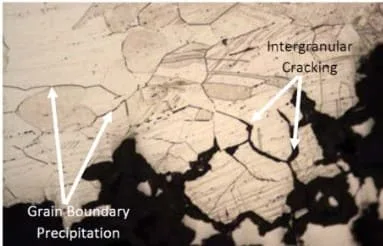

Solution Annealing of Stainless Steel is a process in which stainless steel metal is heated to a temperature above its critical point and then cooled rapidly to restore back its original microstructure that is free from carbide precipitation.

Austenitic stainless steel fabrications rarely require postweld heat treatment. Critical fabrications are sometimes solution annealed to re-dissolve the precipitated carbides in the HAZ, which may cause intercrystalline corrosion in service; or to relieve the stresses that may lead to stress-corrosion in service.

Solution annealing Process

Solution heat treatment consists of heating the entire weldment to the temperature range of 1,025-1120° C, to put the carbides back into solution and cooling it rapidly by water quenching.

The main steps in the solution annealing process are

- Controlled heating above the recrystallization temperature, and

- Rapid quenching in a water bath.

Solution annealing Temperature

The recommended solution annealing temperatures for different Stainless Steel grades are given in Table below:

| Material Grade | Temperature °C |

|---|---|

| 201, 202, 301, 303, 304, 304L, 305, 308 | 1010- 1120°C |

| 309, 309S, 316 | 1040- 1120°C |

| 316L, 317L | 1040- 1120°C |

| 317 | 1066- 1120°C |

| 321 | 954- 1066 |

| 347, 348 | 982- 1066 |

Solution annealing Standards

There are many different standards that dictate how solution annealing should be performed.

The most common standard is ASTM A240, which covers the requirements for steel plates that are to be used in pressure vessels.

In ASTM 240, Clause 6: Heat Treatment, Solution annealing requirements are provided for Austenitic stainless steel grades such as 309H, 310H, 321, 347 and 348.

The Solution annealing of these grades shall be carried out at a temperature above 1950 °F (1065°C).

Other Solution annealing standards for reference are:

- ASTM A 249

- ASTM A312

- ASTM A 358

- ASTM A 376

- ASTM A 403

- ASTM A 409

The above standards are stainless steel material specifications that covers the requirements for solution annealing temperature and other conditions.

Solution annealing of SS316

Solution annealing is a heat treatment process typically used to improve the properties of stainless steel.

The process involves heating the steel to a temperature above its critical point, and then cooling it rapidly.

This allows for the formation of a more uniform microstructure, and can improve resistance to corrosion and mechanical damage.

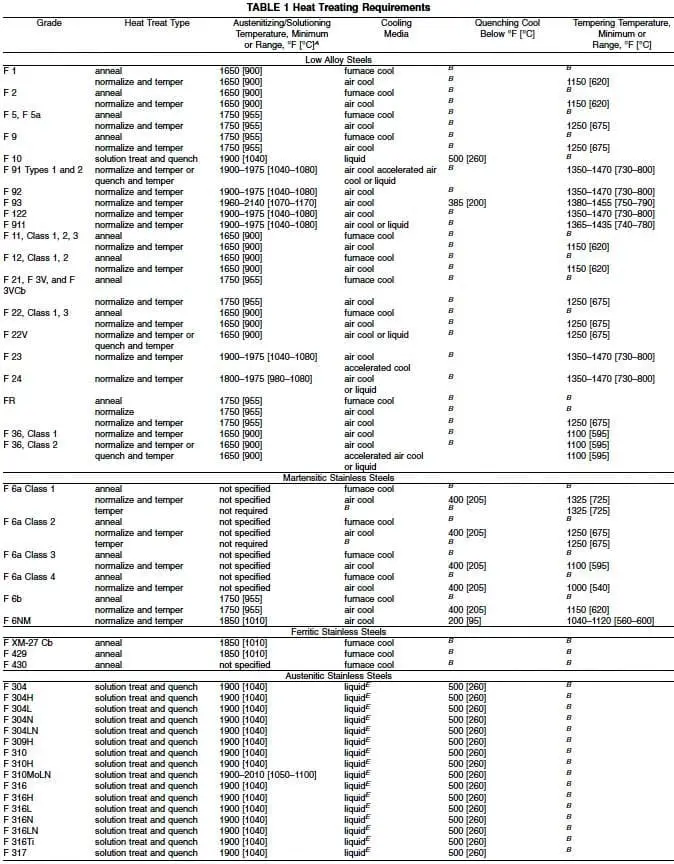

The Solution annealing of SS316 is given in the table above. Below is the Solution annealing chart for Low alloy steel, martensitic stainless steel, ferritic stainless steel and austenitic stainless steel. Reference: ASTM A182).

Solution annealing of Duplex stainless steel

Solution annealing of duplex stainless steel is a process that involves heating the steel to a temperature between 1020 and 1100 degrees Celsius, followed by rapid cooling in water.

This process is used to improve the corrosion resistance and mechanical properties of the steel. Solution annealing can be performed in air, nitrogen, or vacuum furnaces.

Solution annealing of Alloy 800 & 800HT

Solution annealing of Alloy 800 & 800HT shall be carried out at a temperature as given below:

- 1900°F [1040°C]: UNSN08800

- 2050°F [1120°C]: UNSN08810

- 2100°F [1150°C]: UNSN08811

- 2000°F [1100°C]: UNSN08904

The cooling shall be by water cooling or other rapid cooling media.

Solution annealing vs Quenching

The heat treatment process of solution annealing vs quenching is vital to many industries. Both solution annealing and quenching looks similar process but their objectives is different.

Solution annealing is often used to restore original material structure & applied to materials those are prone to carbide precipitation. The metal is heated to a temperature above its critical point and then allowed to cool slowly. This allows dissolution of carbides and re-solidification to austenite phase.

Related reading: Annealing vs Normalizing: What’s the Difference?

Quenching, on the other hand, is used to harden metals and applicable to high carbon steel and low alloy steels. The metal is heated to a temperature above its critical point and then cooled quickly by immersion in water or oil.

| Solution Annealing | Quenching |

|---|---|

| To restore original material structure | To increase hardness |

| For stainless steel and other other austenitic materials | For high carbon steel & low alloy steels |

| Improve properties such as ductility, homogeneity, and reduce stresses | Hardness improved |

| Fast cooling required | Fast cooling required |

| Subsequent heat treatment not required | Usually required tempering after quenching |

Solution annealing can improve the ductility and toughness of a metal, while quenching can improve the hardness and strength of a metal. Both processes involve changing the microstructure of the metal, which can ultimately improve its mechanical properties.

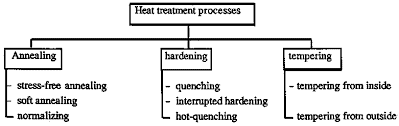

Solution annealing vs annealing

Solution Annealing of Steel is a process in which metal is heated to a temperature above its critical point and then cooled rapidly to restore back its original microstructure that is free from carbide precipitation.

Annealing, on the other hand, is a process of heating and cooling a metal in a controlled cooling rate. Annealing improves the ductility, reduce brittleness, or relieve stresses from previous processes in the components.

Solution annealing is typically done at a higher temperature (Above recrystallization temperature) than annealing. Annealing, on the other hand, is done at a lower temperature (below recrystallization temperature).

Solution annealing bright annealing

Solution annealing is a process in which a material is heated to a high temperature and then cooled rapidly. This process allows for the atoms of the material to rearrange themselves into a more stable configuration.

Bright annealing is a type of solution annealing that is carried out in a vacuum or a controlled atmosphere with inert gases (e.g., argon). This process results in a higher quality final product.

Limitations of using Solution Annealing for Welded Parts

This method is seldom used because of the following unfavourable factors:

a) At the high temperature used, the steel oxidizes rapidly and forms an adherent surface scale, unless it is protected from air.

b) The weldment may sag or be severely distorted at the high temperature used or during rapid cooling from it.

c) Water quenching of a large workpiece from the high temperature can be hazardous.

d) The workpiece is often too large for the furnace and cooling facilities available in the shop.