What is Electrode Extension (Stickout)?

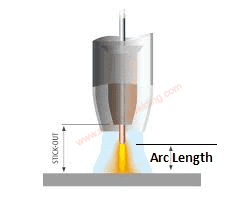

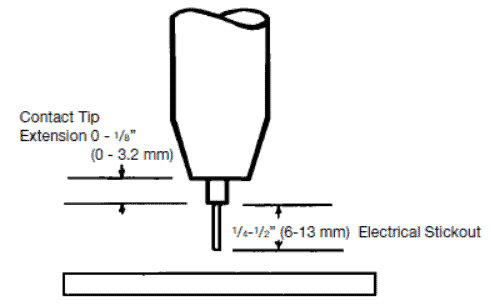

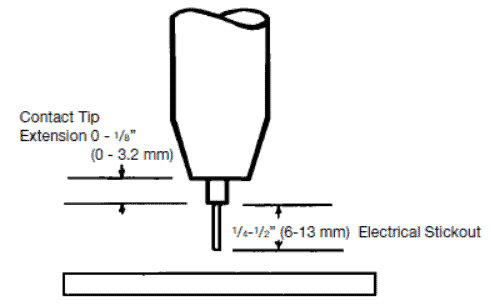

Electrode extension or also called Electrode stickout length or stick-out distance refers to the length of the welding wire that extends outside the contact tube as shown in the below figure.

The welding filler wire gets preheated due to electric resistance in stick-out length after leaving the contact tube. The welding electrode/ filler wire extension by the stick-out length influence the burn-off rate and the weld bead profile.

Welding current and voltage are related to the electrode stick-out length. A higher stick-out means a higher voltage and hence a wider weld profile. Same, time the welding current will be decreased and indirectly affects the depth of penetration and melt-off rate.

Generally, stick-out length in MIG-MAG welding is kept from 1/8 inches to 1/4 inches (3.2 mm to 6.4 mm).

What is Contact-tip-to-work distance (CTWD)

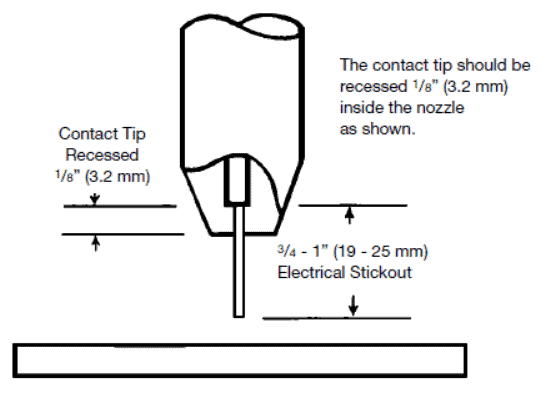

Contact tip to work distance or CTWD means the distance from the contact tip to the workpiece as shown in the above figure.

The right time to accurately check the CTWD is before the start of the weld. Once, welding is started, CTWD is no more practical terms & is replaced by the arc length.

Here, arc length is measured by welding voltage and electrode extension by the resistance in the welding circuit. Refer to the above figure again and notice that: CTWD is equal to the sum of arc length and electrode stickout/ extension.

The CTWD or contact tip-to-work distance influences the welding current as to its effects on the wire extension in MIG-MAG (GMAW) welding.

Refer to the below graph and you will notice that increasing the CTWD will decrease the welding current which in turn decreases the wire melt-off rate.

Simply, the higher the CTWD- the higher the electrical resistance. To maintain, the high welding current, it’s essential to keep the contact tip to work distance at a minimum, thus enhancing the welding productivity.

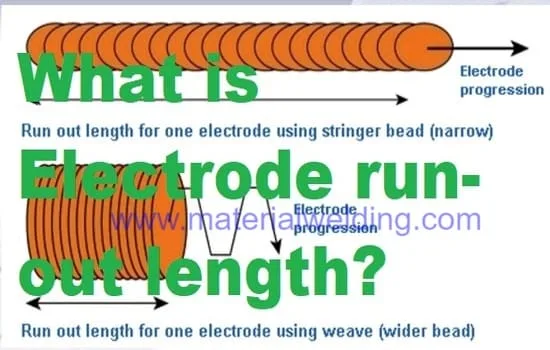

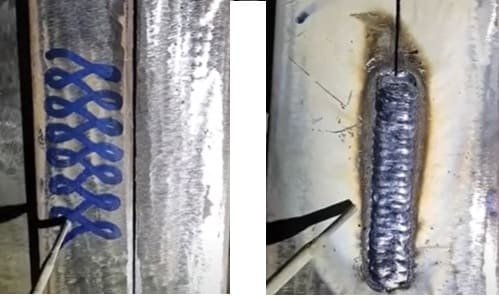

Short electrode stickout gives a narrow weld and a long stickout results in a wider weld.

Importance of electrode stick out

The basic control setting for low conductivity electrode metals is very much dependent upon the electrode stick out.

Variation in electrode sticks out results in a change in the electrical characteristics of the balanced system, as determined by the resistivity of the electrode length between the contact tip and the arc.

Generally, as the contact tip-to-work distance (CTWD) is increased, the I2R heating effect is also increased, hence decreasing the welding current (I) required to melt the welding rod/ filler wire (in effect, increasing the deposition rate for a given current level).

Conversely, as the contact tip-to-work distance is decreased, the I2R effect is decreased, thus increasing the welding current requirements for a given wire feed speed (in effect, decreasing the deposition rate for a given current level).

This point emphasizes the importance of maintaining proper nozzle-to-contact tip distance in welding gun maintenance, as well as the importance of maintaining good welding techniques through proper gun positioning.

Electrical stick out the distance for short circuit transfer mode

Stick-out length for shirt circuit mode shall be kept low as the distance need to be kept minimum to allow a short circuit of the welding wire with the workpiece.

A stick-out length of 6- 13 mm gives good results in GMAW short circuit metal transfer mode.

Electrical stick out the distance for Spray transfer mode

Stick-out length for spray mode requires to be kept longer as wire melts without any short circuit. a stickout length of 19- 25 mm gives good results in GMAW spray transfer mode as shown in the below figure.

What are the effects of using a long electrode extension?

The main effects of using a long electrode extension are:

- Increase in welding voltage.

- Decrease in welding current.

- Wider weld bead.

- Decrease in weld penetration.

- Chances of undercut.

- Reduction in welding heat input.

Similar Posts: