Gas Welding Flame

Gas welding is a type of welding that uses a gas flame to melt and join metals. The gas flame is used to heat the metal so that it becomes malleable-molten and can be joined together.

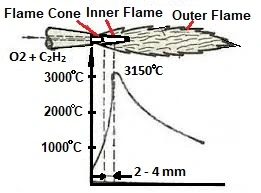

A gas flame is the result of gas mixture (oxygen + Acetylene) ignition that comes out of the torch nozzle. This gas flame is made of flame cone & the outer flame.

Gas welding is a popular choice for many welders because it is relatively simple and does not require special equipment. Gas welding can be done with a variety of gases, including oxygen, acetylene, propane, and natural gas.

Second, gas welding flames can be controlled more easily than other types of flames. This makes them perfect for delicate projects or those that require precise welds.

Parts of a Gas Welding Flame

One of the most common welding flames is the gas welding flame, which is produced by a gas fuel welder. The gas welding flame has three distinct parts:

- Flame cone: Partial combustion of fuel gas (E.g., C2H2)

- Inner Flame: working area of the welding flame. The maximum temperature (around 3200°C) of a welding flame is found in this envelope.

- Outer flame: Complete combustion of the gas.

The outer envelope is the hottest part of the flame and is used to weld metal. The outer envelope protects the weld from oxygen and other elements. The tip of the flame is used to protect the weld pool from oxidation.

Three (3) Types of Gas Welding Flames

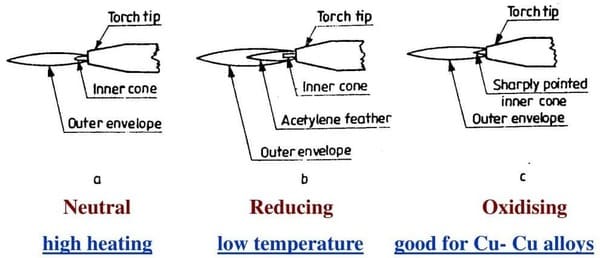

There are three types of flames that can be produced when welding with a gas torch:

- Neutral flame,

- Reducing flame, and

- Oxidizing flame.

Each type of flame has its own characteristics and produces different results when welding.

The neutral flame is the most efficient of the three flames and is produced when the oxygen and fuel gases are mixed in a ratio of 1:1. This flame is used for most welds.

It produces a hot, soot-free flame that is well suited for most welding applications.

The reducing flame is produced by adding more fuel to the oxygen stream. This type of flame produces a hotter, more intensely focused beam of heat that is ideal for cutting and welding metals that are difficult to weld.

The oxidizing flame is produced by adding more oxygen to the fuel stream.

In summary, the neutral flame is the most commonly used and is produced by a mixture of oxygen and acetylene.

The carburizing flame is produced by a greater amount of acetylene in the mixture, and is used for welding metals that are prone to oxidation.

The oxidizing flame is produced by a greater amount of oxygen in the mixture, and is used for welding metals that are not prone to oxidation.

Gas Welding Flames and their applications

Carburizing Flame in Gas Welding

Carburizing flames results due to higher acetylene amount during operation. They are produced by gas welding torches when they are not operated with the correct fuel to oxygen mixture.

The result is a flame that has too much carbon in it, which can cause the weld to be brittle and weak. Carburizing flame produces hardening effect.

Operators must be careful to maintain the right mixture of fuel and air when using a gas welding torch.

To avoid this problem, operators must be trained to use the gas welding torch correctly. They should also have a good understanding of how to mix the fuel and air properly. With this knowledge, they can produce strong, reliable welds that will hold up under stress.

Carburizing flames are often used in gas welding applications where it is necessary to weld high carbon material.

Neutral Flame in Gas Welding

When it comes to gas welding, the type of flame you use can make all the difference. A neutral flame is often seen as the best option, as it provides a good balance between heat and speed.

Neutral flame is a type of gas welding flame used in oxy-fuel welding, oxy-acetylene welding, and other similar processes.

The neutral flame has a nearly equal mix (1:1) of oxygen and fuel gas (e.g., Acetylene or LPG), resulting in a somewhat “neutral” combustion. This type of flame is used for most general purpose welding applications.

While the neutral flame is the most common type of gas welding flame, it is not always the best choice for every situation.

For example, if you are working with metals that are particularly difficult to weld, you may need to use a slightly oxidizing or reducing flame. However, for most general purpose welding applications, the neutral flame will provide the best results.

Oxidizing Flame in Gas Welding

An oxidizing flame is the result f high amount of oxygen compared to acetylene (fuel gas) in a welding flame. The oxygen in the air reacts with the metal being welded, which creates a hot, intense flame.

This type of flame is used to weld metals that are not easily oxidized, such as steel and stainless steel.

The temperature of a oxidizing flame is 6300ºF (3482ºC) due to complete burning of fuel gas.

The main benefit of using an oxidizing flame is that it creates a strong weld. The high temperature of the flame melts the metal and allows it to flow together, creating a solid bond.

However, this same high temperature can also cause problems. If the metal being welded is not properly protected from the oxygen in the air, it can become oxidized and weak.

When welding with an oxidizing flame, it is important to use the correct tip for the gas being used. If the wrong tip is used, the oxygen will combine with the metal being welded, resulting in an inferior weld.

FAQS:

Gas Welding Flame Temperature

When using a gas welding torch, the flame temperature can reach up to 6500ºF. The type of gas you are using will affect the flame temperature.

For example, using an acetylene torch will result in a hotter flame than if you were using a propane torch.

The size of the tip you are using will also affect the flame temperature. A smaller tip will result in a hotter flame than a larger tip.

Gas Welding Flame Ratio

There are three different types of gas welding flames, and the gas welding flame ratio is determined by the mix of oxygen and fuel gases.

The oxygen-fuel gas mixture is adjusted to create a neutral flame, which is the hottest and most efficient.

A reducing flame has more fuel than oxygen and is used for heating metals before welding. An oxidizing flame has more oxygen than fuel and is used for welding metals that are difficult to weld.

Which flame is hottest in Gas Welding?

The neutral flame is the hottest and most efficient because it has an equal mix of oxygen and fuel.

The reducing flame has a lower temperature because it has more fuel than oxygen. The oxidizing flame has a higher temperature because it has more oxygen than fuel.

Which flame is good for cutting?

If you’re looking to do some quick and easy cutting, then you’ll want to choose a flame that is good for cutting. But which flame is good for cutting?

There are three types of flames that are commonly used for cutting: the neutral flame, the reducing flame, and the oxidizing flame. The neutral flame is the hottest of the three flames and will therefore cut through material the quickest. However, it can also be the most difficult to control.

The reducing flame is slightly cooler than the neutral flame and produces less heat. This makes it ideal for cutting thinner materials or for getting a clean cut on thicker materials.

The oxidizing flame is the coolest of the three flames and produces the least amount of heat. This makes it ideal for cutting delicate materials or for getting a precise cut on thicker materials.