MAPP gas, a highly combustible fuel gas with intriguing physicochemical properties, serves an array of functional applications requiring intense heat or combustion. This powerful concoction, constituting methylacetylene-propadiene and propane, is frequently employed within industries for brazing, soldering, cutting, and welding activities, underpinning the critical relevance of understanding its burning temperatures.

As such, gaining insight into the interaction of MAPP gas and oxygen, the consequential burn temperature, and its measurement becomes indispensable. Furthermore, the importance of respecting this gas’s burn temperature and observing stringent safety protocols cannot be overstated, given its vigorous reaction and associated hazards.

Overview of Mapp Gas

What is Mapp Gas?

Mapp gas, originally named for the Methylacetylene-Propadiene Propane it contains, is a type of gas commonly used in high-temperature applications such as metalworking and welding.

It’s a stable, high-energy fuel with a rich, blue flame making it an excellent choice for heating, soldering, and brazing operations. Mapp gas is colorless in its natural state and has a faint petroleum-like odor.

Composition of Mapp Gas and Its Common Uses

Mapp gas is a mixture of various hydrocarbons, primarily methylacetylene and propadiene. It may also contain traces of other hydrocarbons such as propane. It’s a stable concoction that provides a high heat output.

Common uses for Mapp gas are numerous due to its versatility. It’s used in the plumbing industry for soldering and brazing pipes, in the refrigeration industry for brazing copper pipes, and in the jewelry industry for melting and shaping precious metals. Because of its high temperature, Mapp gas is also often used for cutting, heating, and bending metals in the manufacturing and construction industries.

Significance of Burn Temperature

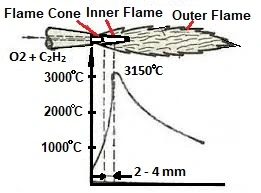

Understanding the burn temperature of Mapp gas is essential for safety and efficiency in its usage. Mapp gas can achieve a flame temperature of nearly 5300 degrees Fahrenheit when burned in oxygen, making it one of the hottest burning gases available. When combined with air, it can reach temperatures of approximately 3600 degrees Fahrenheit.

The high burn temperature permits the use of Mapp gas in applications where extreme heat is required. For instance, in metalworking, high heats are needed to manipulate heavy-duty materials. The elevated temperature enables the gas to penetrate deeper into the normal working alloy, ensuring a thorough, consistent heat application during processes such as brazing or soldering.

However, the superior burn temperature also mandates strict safety protocols. Users should always wear appropriate protective gear to shield themselves from potential burns and other hazards. Knowing how hot Mapp gas can burn allows professionals to use it knowledgeably and safely.

Physicochemical Properties of Mapp Gas

Understanding Mapp Gas: Basics and Composition.

Mapp gas, also known as Methylacetylene-Propadiene Propane, is a type of liquefied petroleum gas specifically designed for high-temperature applications. It was first introduced as a cost-effective alternative to acetylene, favored for its similar characteristics and burning temperatures while being regarded as much safer to handle and store.

Mapp gas is composed of a stable mixture of various hydrocarbons, primarily methylacetylene (C3H4) and propadiene (C3H4). Other components include propane (C3H8) and butane (C4H10). This unique blend provides it with a higher combustion temperature compared to other alternatives on the market.

Exploring the Combustibility of Mapp Gas.

The combustibility of Mapp gas is largely due to the presence of methylacetylene and propadiene in its composition. These hydrocarbons are highly reactive and exhibit extensive flammability ranges.

Mapp gas is known to burn at extremely high temperatures. With oxygen, the combustion temperature can reach approximately 5300 degrees Fahrenheit (2927 degrees Celsius) or 3600 degrees Fahrenheit (1982 degrees Celsius) in the air.

It’s important to handle Mapp gas carefully because of its highly combustible nature. Secure storage and usage protocols are necessary to prevent uncontrolled reactions, fires, or explosions.

Mapp Gas Reaction with Oxygen.

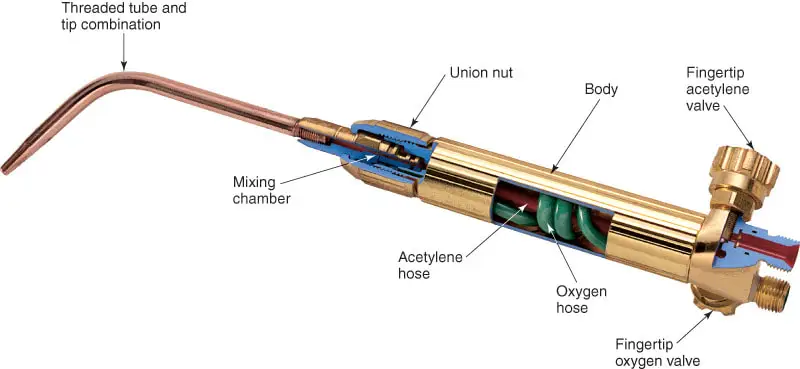

In addition to being highly flammable, Mapp gas is also known for its vigorous reaction with oxygen. When Mapp gas is combined with oxygen in a torch or similar device, the result is a high-heat flame ideal for various heating applications, such as soldering or brazing.

The reaction of Mapp gas with oxygen can be summarised with a combustion reaction equation. Here, the hydrocarbons in Mapp gas react with oxygen to produce heat, water vapor, and carbon dioxide.

Safety precautions should be taken to avoid leakage or unintended ignition during this reaction. This could cause a blowback or dangerous release of heat and gas that could potentially lead to injury or damage to equipment. Always ensure that torches or other devices utilizing Mapp gas in oxygen-rich environments are used and maintained properly.

Practical Uses of Mapp Gas’ Combustion Properties

The high combustion temperature and energetic reaction with oxygen make Mapp gas particularly well-suited to high-temperature applications. It is commonly used in metalworking and plumbing for welding, soldering, and brazing, where the high heat allows for rapid and efficient joining of materials.

Moreover, Mapp gas torches are favorably used in the HVAC industry for their power and precision, enabling professionals to conduct intricate heating procedures effectively and safely.

Burn Temperature Measurement

Understanding Burn Temperature

Burn temperature, also known as flame temperature, is the measure of heat output in a flame during combustion. Mapp gas, commonly used in metalworking due to its high burn temperature, is often used as a reference for high-temperature processes.

Measurement of Mapp Gas Burn Temperature

Digesting the specifics of how to actually measure the burn temperature of Mapp gas is slightly more sophisticated than it first appears. Usually, this temperature is found through the use of a simple combustion calculation or for more precise readings, thermocouples and pyrometers are frequently used.

Utilizing Combustion Calculations

This method uses known heat of combustion values for various gases and assumes complete combustion in a perfect stoichiometric ratio, meaning that the right amount of oxygen is present for the gas to be completely burned. Mapp gas, consisting mainly of propyne and propane, can be expected to have a flame temperature in oxygen of about 2927 degrees Celsius (5300 Fahrenheit). Bear in mind this is a theoretical value, and actual results will be less due to inefficiencies in the burning process.

Applying Thermocouples

A more direct method of measuring burn temperatures is with a device known as a thermocouple. This is a probe consisting of two different metals welded together at the tip, which generates a tiny electric voltage proportional to the temperature. This voltage can be read by a suitable meter and converted to a temperature reading.

Using Pyrometers

Another instrument that can be used to get a somewhat direct reading is the pyrometer, an instrument that measures high temperatures by using the principle of black body radiation. Basically, it measures the brightness of the flame at a specific wavelength and calculates the temperature from that.

Safety Precautions

It is important to note that measuring the burn temperature of Mapp gas, or any other burn temperatures for that matter, should exclusively be performed in a controlled environment with safety precautions in place. It is essential to wear heat-resistant gloves and safety goggles, as extreme temperatures can pose serious hazards.

By understanding these processes and using the correct measurement equipment, it is possible to calculate and compare the relative burn temperatures of many different gases, including Mapp gas.

Safety Considerations

Understanding Mapp Gas

Mapp gas, short for methylacetylene-propadiene propane, is a high-performance fuel gas often used for metalworking tasks. Among various gases used for soldering and brazing applications, Mapp gas stands out because of its ability to burn at very high temperatures.

Determining the Burn Temperature of Mapp Gas

Mapp gas burns at approximately 5300 degrees Fahrenheit or 2927 degrees Celsius when mixed with oxygen. However, in an open air environment where it’s mixed with regular ambient air, the burn temperature is generally lower, around 2800 degrees Fahrenheit or 1538 degrees Celsius. This significant temperature difference underlines the need for appropriate safety measures when handling and using Mapp gas.

Safety Precautions when Using Mapp Gas

Handling a fuel gas that can burn at such high temperatures requires strict safety measures. Here are some steps to follow:

- Wear protective clothing: Always wear heat-resistant gloves, safety glasses, and a flame-resistant apron before using Mapp gas to protect your body from potential burns.

- Secure the gas cylinder: Ensure the Mapp gas container is securely fastened during use to prevent accidental toppling, which could cause leakage.

- Maintain a safe distance: Keep all non-essential items and uninformed personnel at a safe distance from the work area to avoid accidental exposure to the heat.

- Ventilation: Ensure proper ventilation in the workspace to prevent the buildup of gases that may pose a health risk or could trigger an explosion if ignited.

- Use appropriate torches: Since Mapp gas can burn at very high temperatures, using a torch designed to handle such heat is crucial. Regular propane torches might not be suitable for Mapp gas.

- Check for leaks: Always check for potential leaks in the gas cylinder and torch prior to use.

Emergency Protocols for Mapp Gas

Knowing what to do in case of an emergency is as important as the preventive measures. Listed below are some protocols to follow:

- In case of minor burns, immediately run cold water over the affected area.

- In case of a major burn or if there’s difficulty breathing due to gas inhalation, dial 911 for immediate medical attention.

- Should a fire occur due to Mapp gas, use a fire extinguisher rated for B (flammable liquids/gas) fires.

- In case of a gas leak, if possible, immediately shut off the valve on the Mapp gas cylinder. If not, evacuate the area and call the fire department.

Remember, the key to safe usage of Mapp gas lies in understanding its properties, respecting its potentials, and taking the necessary precautions.

Overall, the deep dive into MAPP gas’s characteristics, its burn temperature, its measurement, and safety measures associated with its use offers us a comprehensive understanding of this potent substance.

Significantly, the gauge of its burn temperature reveals the intense heat and energy it discharges, underlying its widespread use in multiple industries. Moreover, understanding how to measure this temperature ensures an accurate perception of its capabilities and limitations.

And lastly, knowledge of necessary safety protocols reassures us of the caution required when dealing with MAPP gas, further emphasizing the inherent importance of being informed on the subject. Therefore, the insights derived throughout this exploration equip users with crucial knowledge that can significantly enhance their safety and efficiency while handling MAPP gas.