What is EDM Wire Cutting?

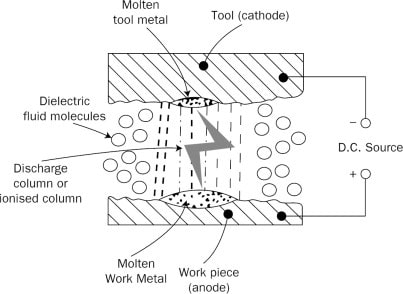

Electrical Discharge Machining, or the EDM wire cutting process is an electro-chemical cutting method. This method removes materials by using a controlled and fast frequent electrical charge.

The process is applicable only for electrically conductive materials such as metals. A specially designed tool emits sparks in terms of thousands & cut the material.

Electric Discharge Machine is new & advance material cutting process that offers highly precision cuts but limited to only for electrically conductive materials.

The hardness of material or any oxide layer is not a concern in EDM as long as they are electrically conductive. During the cutting stage, material evaporates, and a cut is formed in the material.

Wire Cut EDM Process

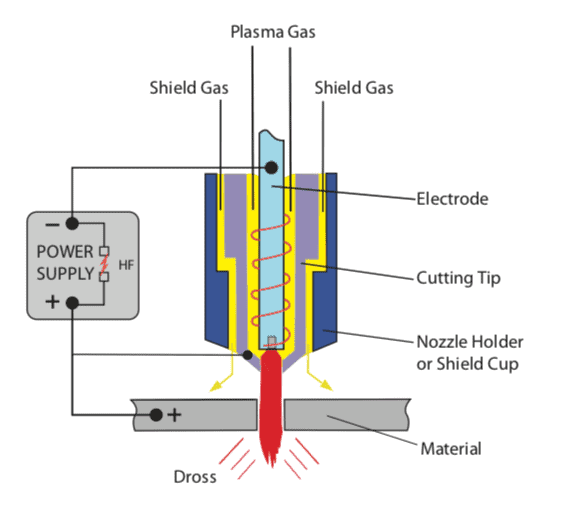

Wire Cut EDM works on the principle that if an electrical potential exists between two electrically conductive materials and the materials are brought near to each other, a discharge will take place once the gap is so small that the potential can create a breakdown in the medium between two materials.

The high temperature generated due to this is enough to convert liquid or gas present in plasma- a high electrically conductive media. Wire Cut EDM electrodes are separated by a dielectric hydrocarbon oil.

Wire cut EDM is a machining process that uses electrical discharges to cut metal. It is a versatile and precise method that can be used to create complex shapes. Wire cut EDM is typically used for hard metals, such as stainless steel or titanium, but can also be used on softer metals. The process works by passing a thin wire through the workpiece and using electrical discharges to vaporize the metal. The wire is then moved in small increments to create the desired shape. Wire cut EDM is a fast and efficient way to produce high-quality parts.

What are the advantages of EDM?

- High Accuracy for 2 axis cutting of small components.

- High precision tolerances cutting.

- Cutting without any thermal cutting effect on material or we can say burn-free cuts.

- Suitable for cutting complex shapes.

- Cutting of material having low hardness or very high hardness- hardness of material does not matter.

- As many as 10 electrodes are often used at one time.

- Useful for Special Shapes.

- Hardness of a material is not a concern for EDM cutting.

What are the Disadvantages of Wire EDM Cutting?

- Slow cutting speed- Not suitable for high production.

- EDM only works for material those are electrical conductor.

- Not suitable to cut tubing as tubing material will deform due to pressure from holding jig.

- High cost of cutting equipment- High initial investment.

- Tools require replacement.

What is the differences Between Wire Cut and Conventional EDM?

The electric discharge cutting process has below groups:

- Conventional/ Sinker EDM

- Wire cut EDM.

As stated earlier, conventional EDM deploy tools (Cathode) to distribute current through the work (anode) & evaporate the material to make a cut.

The small chips produced by the process are washed out of the workpiece through a dielectric media (oil in the cutting bath) where the Tool and the material to cut are immersed.

Wire cutting electric discharge machine acts as a cathode and draws current through tight, fine wires that are guided along the cut. The dielectric media is washed by the kerf, helping to remove chips and regulate sparks.

Fine wires allow precise cutting with narrow cuts (~ 0.015 “usually available with finer cuts) and +/- 0.0001” tolerances. This increased accuracy allows for critical 3D cutting and produces precision tools, dies and other critical shape geometries.

The wire electric discharge machine is equipped with computer-controlled (CNC) equipment, thus gives a perfect cutting path. Changing the cutter path creates a simple cut, and adding a motion axis to the wire guide creates a more complex cut. Both 4-axis and 5-axis wire EDMs machines can be purchased from the market.

Wire Cut EDM makes more complex and critical cuts compared to the conventional Electric Discharge Machine.

Advantages of wire EDM over conventional EDM

Wire EDM is a type of electrical discharge machining that uses a thin wire electrode to cut conductive materials. Wire EDM is faster and more accurate than conventional EDM, and it can be used to cut complex shapes that would be difficult or impossible to cut with conventional EDM.

Wire EDM is particularly well suited for cutting hard metals such as stainless steel and tool steel, as well as non-conductive materials such as ceramics and composites. The ability to cut these materials makes wire EDM an attractive option for many manufacturing applications.

Wire EDM has several advantages over conventional EDM, including:

1. Increased accuracy – Wire EDM machines can hold tolerances of +/- 0.0002 inches or better. This level of precision is difficult to achieve with other machining processes.

2. No tooling required – Since the wire does not come into contact with the workpiece, there is no need for special tooling or fixtures. This makes wire EDM an ideal choice for prototype development or low-volume production runs.