Eddy Current Non-Destructive Testing (ECT) is a powerful inspection technique used in various industries. Discover how ECT detects surface and subsurface flaws without causing damage. Get insights on its applications, benefits, and limitations. Explore the efficiency and reliability of ECT for precise quality control and defect analysis. Uncover the potential of ECT in optimizing your inspection processes for improved safety and productivity. Learn more about Eddy Current NDT and its role in enhancing non-destructive testing practices today!

Eddy Current Non Destructive Testing or ECT is an advance NDT Method used for surface & sub-surface inspection in conductive materials.

What is Eddy Current Testing?

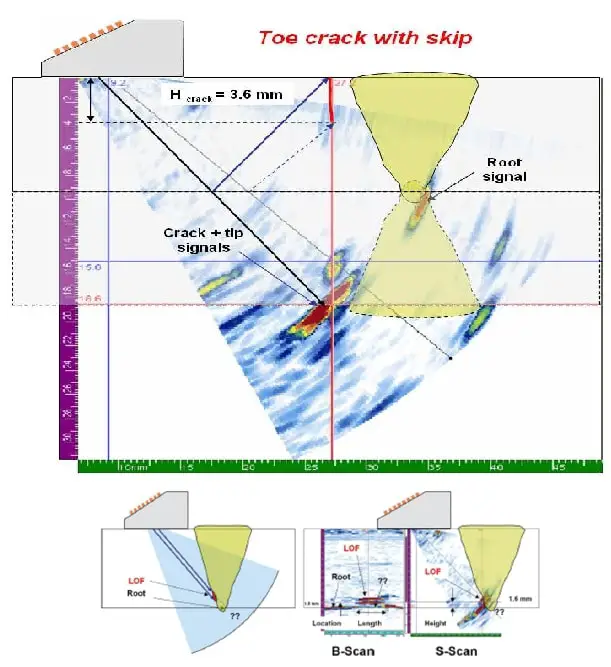

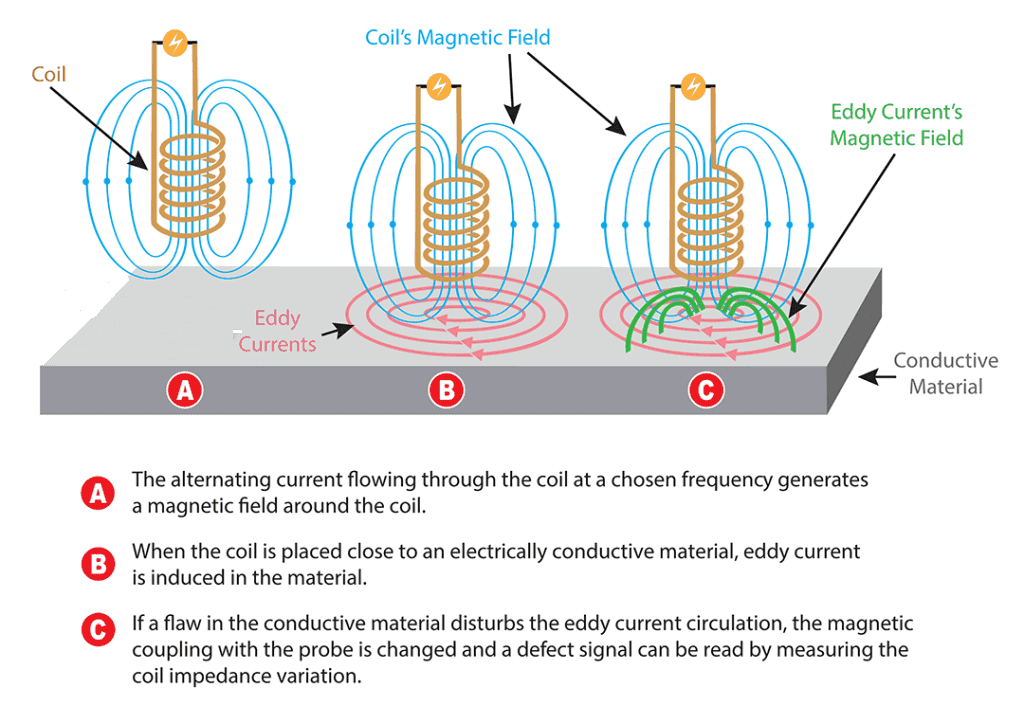

Eddy Current Non Destructive Testing (also called ECT) is an NDT method that works on the electromagnetism principle as shown in the below figure 1. Eddy Current Non Destructive Testing method is used for flaw detection in conductive materials such as steel. During the ECT, an alternating current (AC) is passed through a coil placed in the proximity of the part to be inspected.

The changing current in the coil produces an alternating magnetic field in the weld in the test part. The varying magnetic field in the test object creates an eddy current in the material.

These Eddy currents, which vary with the magnetic field, create their own magnetic field that interacts with the initial field. The test coil, or in some cases a separate pick-up coil, is electrically monitored to detect any change in this field interaction.

Discontinuities or flaws in the material or weld will change the magnitude and direction of the eddy currents and thus be detected through the test signal. These signals are then displayed on a screen (an analog meter, digital meter, CRT, x-y plotter, or strip chart reader) and interpreted to recognize the flaws.

Factors Affecting Eddy current Test (ECT)

The magnitude of the induced eddy currents depends on:

- Magnitude and frequency of the alternating current (AC).

- Electrical conductivity.

- Magnetic permeability.

- The shape of the test object.

- The relative position of the coil and test object.

- Presence of the defects in the object.

- Mechanical and heat treatment of a test object.

How Does Eddy Current Testing Work?

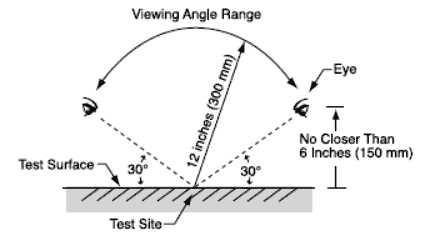

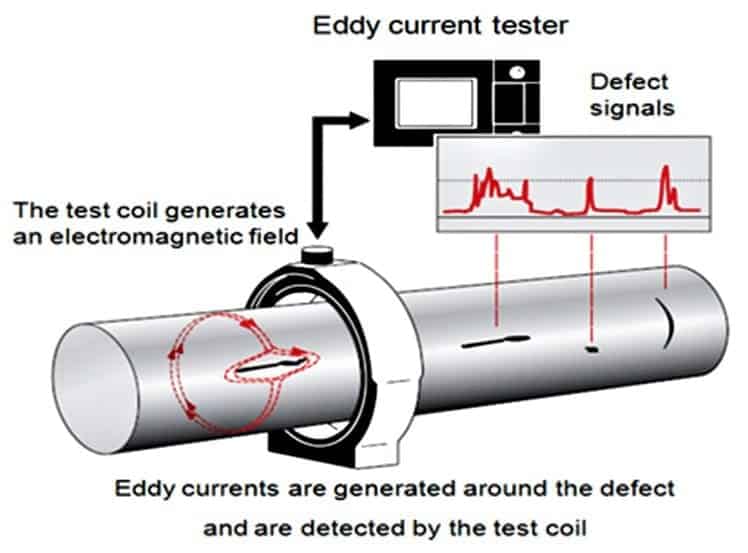

Eddy current testing (ECT) works on the principle of electromagnetic induction physics. When a coil (or an ECT probe)carrying an Alternating current (AC) is brought near a metal test specimen, eddy currents are induced in the metal by electromagnetic induction.

Usually, the currents are induced in the part by making it the core of an alternating current induction coil as shown in the below figure. A crack in part can disrupt the eddy current flow and the magnetic field produced by that current. The magnitude of the eddy current is highest on the outer surface, hence this is the area of maximum test resolution.

The magnitude of the induced eddy currents depends on the magnitude and frequency of the alternating current (AC), the electrical conductivity, magnetic permeability, shape of the test object, the relative position of the coil and test object, and the presence of the defects in the object.

Mechanical and heat treatment of a test object will affect its electrical conductivity. For example, in the case of austenitic stainless steel, mechanical and heat treatment will affect the magnetic permeability.

What is Eddy Current Non Destructive Testing used for & ECT applications?

Eddy current testing is used in many applications ranging from testing of welds, raw materials, finished parts & tube inspection. The main application or uses of Eddy current inspection (ECT) are listed below:

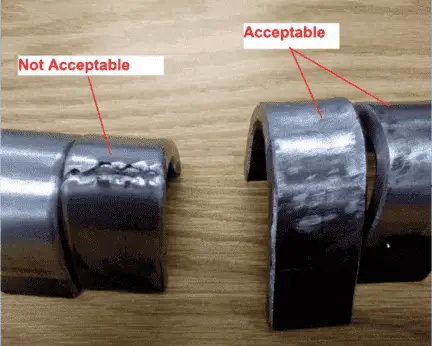

- Welding Inspection– Eddy current is used as a supplementary test along with UT or other NDT methods. It is used to check welding surface defects such as cracks on weldment and HAZ area.

- Material Sorting – Due to the ability of eddy current testing to measure conductivity, it is employed to locate and sort ferrous and non-ferrous material as well as to check the heat-treatment condition of materials.

- Machined parts Inspection – ECT is used to scan machined parts to identify surface cracks as a reliable and fast NDT method. Eddy current inspection is widely employed to carry out NDT inspection of critical components & fasteners used in the aerospace sector.

- Corrosion inspection applications – Eddy current testing is applied to inspect any anticipated corrosion at the inside of thin materials- e.g. aluminum aircraft skin. ECT using low-frequency probes is used on 2nd and 3rd layers of metal which is otherwise not possible to inspect by UT.

- Inspection of Bolt Hole – Eddy current inspection with bolt hole probes is used to find cracks in the fasteners holes such as bolts using automated inspection systems with higher efficiency and inspection rate.

- Inspection of tubes – ECT is widely used for inspecting the heat exchanger tubes to detect thinning due to corrosion or any cracking.

Eddy Current Instruments

Eddy Current Non Destructive Testing (ECT) equipment is available in different types. You can purchase analog and digital types. ECT machines are classified by type of display unit. The main types of Eddy current inspection ECT displays are:

- Analog meter,

- Digital display,

- Impedance plane and

- Time versus signal amplitude.

- Combined display units.

The ECT unit consists of an AC source connected to a coil, and a voltmeter to measure the voltage change in the coil. An ammeter is used sometimes in place of a voltmeter to measure the change in current in the circuit.

Advantages & Limitations of Eddy Current Testing

Advantages of Eddy Current Testing:

- Eddy Current Non Destructive Testing is used for NDT inspection to find surface and sub-surface cracks as small as 0.5mm.

- Eddy Current Non Destructive Testing can be used to find flaws through various metal layers, together with non-conductive surface coatings, without intervention from planar flaws.

- The non-contact ECT technique can be used to check high-temperature areas and underwater locations.

- Fast and reliable for complex geometrical parts.

- Fast test results.

- Lightweight and portable ECT equipment.

- Useful for measuring the electrical conductivity of metals.

- Automated NDT methods for checking uniform objects such as tubes and aero-engine disks.

- Little surface preparation is required in Eddy current inspection.

Limitations of Eddy Current Testing:

- Eddy Current Non Destructive Testing can be applied only for conductive materials, hence the part to be inspected must be an electrical conductor.

- The depth of inspection is usually limited to 6 millimeters for non-ferromagnetic materials and 0.25 millimeters for ferromagnetic materials.

- Not possible to find flaws that are parallel to the test specimen surface.

- Eddy Current Non Destructive Testing require trained personnel for interpretation.

- Eddy Current Non Destructive Testing Equipment of cost is high.

Eddy Current Non Destructive Testing (ECT) Code & standards

- ISO 15549:2008

- ISO 17643:2015

- ISO 10893-1:2011

- E2884-17