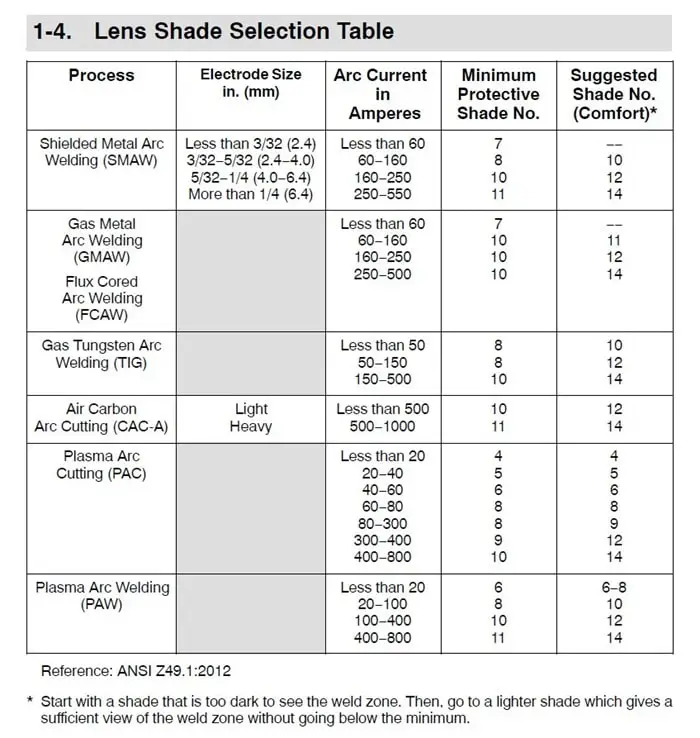

Selecting the right lens shade for welding

The first important point- is never to look at the welding without black safety glass or a helmet of the right shade. Next question- What is the right shade for the glass for different welding processes?

Looking directly at the welding arc without protection or let us say, failure to observe this rule can result in various degrees of eye burn. These burns do not usually cause permanent injury, but they can be very painful for several days after exposure.

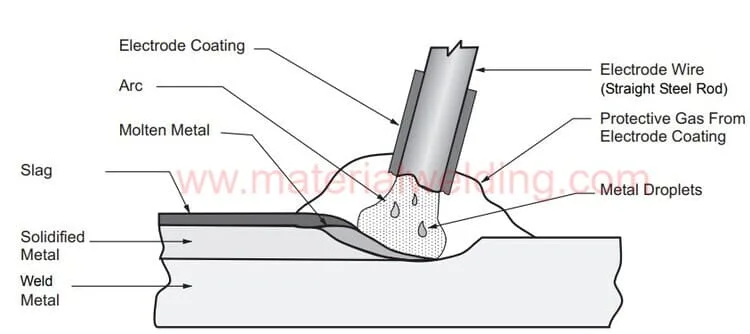

A helmet-type head shield, as shown in below Figure is standard equipment for protecting the welder’s face and eyes from the direct rays of the arc. These shields are generally made from a non-flammable insulating material and are black or gray in color to minimize reflection. They are shaped to protect the face, neck, and ears from direct radiant energy from the arc.

What are the acceptable lens shade numbers for arc welding?

The shields are equipped with a standard-size (2x 4-l/4-in.) glass window through which the welder observes the work in the area of the arc. A proper glass lens screens almost 100% of infrared and ultraviolet rays and most of the visible rays from the welder’s eyes.

The lens should be made from tempered glass, free from bubbles, waves, or other flaws. Except for lenses that are ground for correction of vision, their flat surfaces should be smooth and parallel.

A piece of ordinary colored glass may look like a welding lens, but it would not have the necessary light-screening characteristics needed for eye protection. Special equipment is required to measure the amount of infrared and ultraviolet rays a lens will absorb.

Welding lenses should be purchased only from suppliers who can be depended upon to furnish quality products. Welding lens shades numbers are listed from Number 4 to number 14 in AWS Z49.1. Lens shade numbers 4 to 8 are useful for low light intensity welding & cutting activities such as gas cutting, brazing or soldering, etc.

Lens shade chart for welding

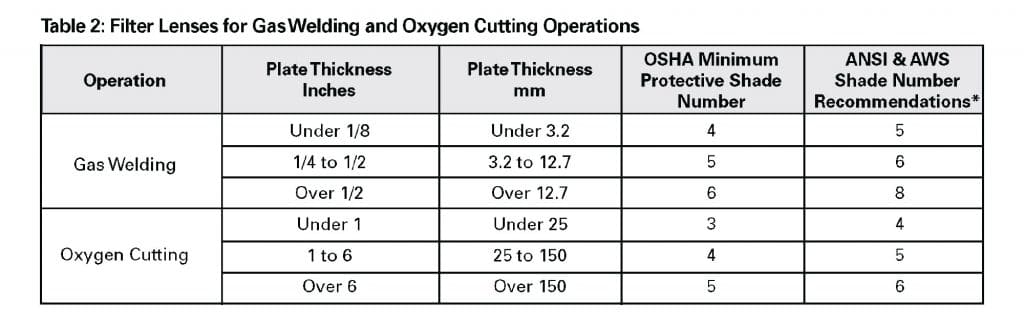

Lenses are available in a number of shades for various types of work. Recommended shade numbers for common welding and cutting operations are listed in below Table (from ANSI Z 49.1, welding safety).

Note that the shade number varies with the electrode-size range in shielded metal-arc welding and with the thickness range of material when oxygen cutting.

What shade lenses are acceptable for most types of welding?

You can easily choose a welding lens shade with the above chart. As you can notice, shade number depends on:

- Welding process

- Welding current

- The intensity of light produced by the welding or cutting process

For example, a gas cutting will require usually a lens shade of 4 to 8 numbers while gouging by air carbon requires a higher number of lens shades, usually 12 to 14 numbers.

What does the welding shade number mean?

Welding lens shades numbers are listed from Number 4 to number 14 in AWS Z49.1.Lens shade numbers 4 to 8 are useful for low light intensity welding & cutting activities such as gas cutting, brazing or soldering, etc.

For gas welding or oxyfuel torch welding, lens shade of 4 to 6 are suited well. For stick welding, an 8 to 10 number is good. High-light intensity welding processes such as plasma arc welding or PAW, need a high number of shades, mostly 12 to 14 shades numbers for the right protection.

Remember, as the number of the lens shade increase, the filter lens becomes darker.

Glass lens shade for Gas welding and Gas cutting

For gas welding or oxyfuel torch welding, lens shade of 4 to 6 are suited well. For oxyfuel gas cutting, the gas lens depends on the material thickness to be cut, and the same for OFW Welding where the thickness to be welded decides the lens shade.

The below table gives details on recommended gas filter shade number for the gas welding and oxygen-cutting process.