This article covers the welding guidelines, chemical compositions and mechanical properties for ASTM A352 LCA, LCB, LCC casting material.

What is ASTM A352 LCA, LCB, LCC Casting?

ASTM A352 specification is for steel casting used for low temperature services.

LC in A352 grades means Low temperature applications. LCA, and LCB are carbon steel casting. LCC is carbon-manganese base cast steel.

The low temperature service ceiling for these grades as per ASTM A352 are:

- LCA −25°F [–32C]

- LCB −50°F [–46°C]

- LCC −50°F [–46°C]

ASTM A352 LCA, LCB, LCC Specification & Equivalent Material

The material specification for Grade LCA, LCB and LCC is ASTM A352. The UNS Number for these grades are:

- ASTM A352 Grade LCA: UNS J02504.

- ASTM A352 Grade LCB: UNS J02505.

- ASTM A352 Grade LCC: UNS J03003.

The welding P Number for LCA, LCB and LCC is P Number 1. LCA and LCB have group number 1 while LCC group number is 2 according to the ASME Section IX.

ASTM A352 LCA, LCB, LCC Chemical Compositions

ASTM A352 LCA and LCB are carbon steel casting while LCC is Carbon-manganese steel casting for low temperature services.

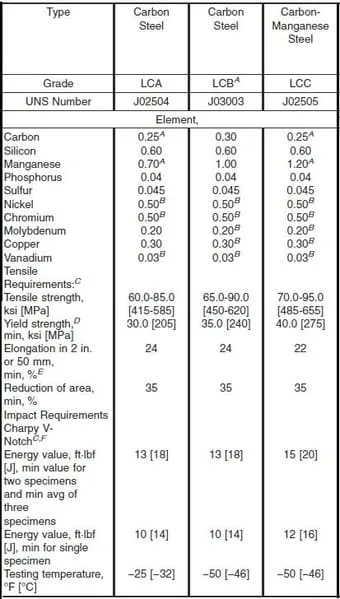

Chemical compositions, yield, tensile strength and toughness for Grade LCA, LCB and LCC are given in the below table. (Reference ASTM A352 specification).

ASTM A352 LCA, LCB, LCC Mechanical Properties

The tensile strength of ASTM A352 LCA is 60- 85 Ksi (415- 585 MPA). Grade LCB tensile strength is 65- 90 Ksi (450- 620 MPA) and grade LCC tensile strength is 70- 95 Ksi (485- 655 MPA).

Refer table above for complete mechanical properties for Grade LCA, LCB and LCC as required by ASTM A 352 specification.

ASTM A352 LCA, LCB, LCC Welding Procedure

The welding of ASTM A352 grade LCA, LCB and LCC can be carried out using stick welding (SMAW), TIG and MIG welding as well using flux core and SAW process.

For stick welding grade LCA, LCB and LCC, you can use E7018-1 welding rod. E7018-1 is a carbon steel electrode as per AWS A5.1 specification with improved weld toughness properties.

For TIG and MIG welding for LCA, LCB and LCC, you can use ER70S-2 filler wire rod. ER70S-2 is triple deoxidizer welding wire with high weld deposit toughness.

Although, for welding of grade LCC, it is recommended to use ER80S-Ni or E8018-C1 stick welding rod. These filler rods are with added nickel for higher weld metal toughness.

Welding Preheat for ASTM A352 LCA, LCB, LCC

Welding of ASTM A352 Grade LCA, LCB, and LCC can be welded without any welding preheat.

Although, when welding at sub-zero temperature or in cold weather, apply a minimum welding preheat temperature of 50°F (10°C).

Welding interpass temperature should be kept below 500°F (260°C).

PWHT for ASTM A352 LCA, LCB, LCC Welding

Heat treatment is generally not required for carbon steel casting grades such as LCA, LCB and LCC.

In case of major casting repair, you can perform a PWHT at a temperature of 600 °C for 1 hour duration to relieve the residual stresses.