ER70S-2 (CSA W48 ER495-2) TIG MIG Rod Meaning

ER70S-2 is a triple deoxidizer (Titanium, Zirconium & Aluminum) carbon steel welding filler rod.

Deoxidizers are the elements that easily react with oxygen to make their compounds e.g., Aluminum reacts with oxygen and makes AlO2 (Aluminum oxide) thus preventing the adverse effect of oxygen in the weld.

ER70S-2 due to added deoxidizers are especially beneficial for welding on dirty or rusty surfaces. ER70S-2 gives weld of high toughness properties and high weld quality.

It is used for single-pass and multipass welding of carbon steel, low alloy steel, mild steel, and cast steel welding.

ER70S-2 Welding Wire Specification- Classification

ER70S-2 is a TIG & MIG solid wire classification according to the AWS A 5.18 specification. CSA W48 equivalent classification of ER70S-2 is ER495-2 (B-G 49A 3 CG2).

ER70S-2 is the filler wire rod classification while AWS A5.18 is the filler wire rod specification. AWS A5.18 contains all the minimum requirements for chemical composition, mechanical properties, and usability characteristics for the ER70S-2 filler wire rod.

ER70S-2 Chemical Composition

ER70S-2 chemical composition requirements are given in the below table for reference. The main alloying elements of ER70S-2 are Carbon, Manganese, Silicon, Titanium, Zirconium, and Aluminum. In this table, single values represent the maximum limit allowed for these elements.

| Element name | Weight percentage as per AWS A5.18 |

| Carbon | 0.07 |

| Manganese | 0.90 – 1.40 |

| Silicon | 0.40 -0.70 |

| Titanium | 0.05- 0.15 |

| Zirconium | 0.02- 0.12 |

| Aluminum | 0.05- 0.15 |

| Nickel | 0.15 |

| Chromium | 0.15 |

| Molybdenum | 0.15 |

| Vanadium | 0.03 |

| Copper | 0.5 |

| Phosphorus | 0.025 |

| Sulfur | 0.035 |

ER70S-2 Mechanical Properties- Yield, Tensile, toughness

The minimum Yield strength of ER70S-2 is 38 Ksi (400 MPa), and the Tensile strength is 70 Ksi (490 MPa). The mechanical properties of the ER70S-2 TIG-MIG Filler wire rod are given in the below Table:

| Properties | Value |

| Yield Strength | 40 Ksi (400 MPa) minimum |

| Tensile Strength | 70 Ksi (490 MPa) minimum |

| % Elongation | 22 minimum |

| Toughness ft.lbf (Joules) | 20 ft·lbf @ –20°F (27J @ –30°C) |

Toughness (Charpy V Notch) of ER70S-2

The minimum toughness required for ER70S-2 TIG MIG Filler Wire Rod is 20 ft·lbf @ –20°F or 27J @ –30°C temperature.

Usually, the toughness of ER70S-2 is higher compared to ER70S-6 as there is less loss of Manganese during welding with ER70S-2.

An all-weld metal test needs to be welded and tested as per AWS A5.18 specification for the verification of filler wire toughness properties.

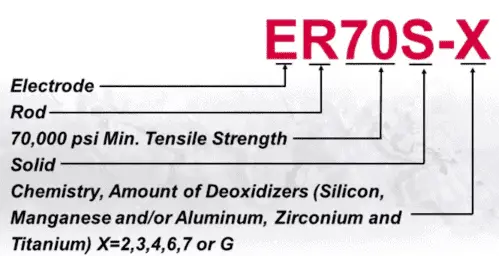

ER70S-2 TIG MIG Rod Meaning

ER70S-2 is a wire classification where each digit give information about the properties and usability characteristics of the ER70S-2 filler wire rod. ER70S-2 TIG MIG Rod meaning as per AWS A5.18 is:

- ER: ‘ER’ Means Electrode or rod.

- 70: means the minimum Tensile Strength in Ksi of the TIG MIG Rod i.e. 70 Ksi

- S: ‘S’ Means Solid filler wire rod

- 6: ‘6’ means the Chemical Compositions of the welding filler wire rod as given in the AWS A5.18 Table 1. Refer below picture of detailed chemical composition for ER70S-2 and other Mild steel filler wire rods.

ER70S-2 A-Number & F-Number

The A-Number of ER70S-2 TIG- MIG Filler wire rod weld is ‘1’. This A-Number is as per ASME Section IX, Table QW-442. A-Number is for mild steel welding consumables.

What is A-Number in Welding & ASME?

The F-Number of ER70S-2 TIG-MIG Filler wire rod is ‘6’. This F-Number is as per ASME Section IX, Table QW-432.

What is ASME F-Number for filler metals?

ER70S-2 Filler Rod for TIG

ER70S-2 Filler Rod for TIG Welding is a mild steel solid wire having triple deoxidizers to make it suitable to weld on the dirty and rusty surfaces as well as welding semi-killed, rimmed, or killed steel in single-pass and multi-pass weld runs.

The standard length of the ER70S-2 TIG Filler rod is 1 meter. ER70S-2 TIG filler rod is available in diameters of 1/8’’, 1/16’’, 3/32’’, and 5/32’’.

ER70S-2 Mig Wire

ER70S-2 Wire for MIG Welding is a mild steel solid wire having triple deoxidizers to make it suitable to weld on the dirty and rusty surfaces as well as welding semi-killed, rimmed, or killed steel in single-pass and multi-pass weld runs.

The standard spool weight of ER70S-2 MIG wire is 33lb spool. ER70S-2 MIG filler rod is available in diameters of 0.035’’, 1/16’’, 0.045’’, and 1/16’’.

Shielding Gases for ER70S-2 Filler Wire Rod

75/25 welding gas, gas cylinder bottle sizes

When using ER70S-2 for TIG welding, pure argon is used as a Welding Gas for weld shielding purposes.

Purging or trailing is not required for ER70S-2 as it is used only for mild steel & carbon steel welding.

75-25 Welding gas (Mixture of 75% Argon + 25% CO2) and pure CO2 are used when ER70S-2 is used for MIG-MAG Welding applications.

Nitrogen even in a small percentage must not be used for shielding when welding with ER70S-2 or any other carbon steel welding wire as Nitrogen will produce welding porosity in Carbon Steel Welding.

Polarity for ER70S-2 Filler Wire Rod

The Welding Polarity for ER70S-2 when used with TIG Welding is Direct Current Electrode Negative (DCEN). Direct Current Electrode Positive (DCEP) Welding Polarity is used for ER70S-2 in MIG-MAG Welding Process.

Click Here to Learn about Various type of Polarity in Welding processes.

ER70S-2 Vs ER70S-6 Tig Rod

Both ER70S-2 and ER70S-6 are mild steel TIG Welding Filler Wire Rods. The main differences between the ER70S-2 & ER70S-6 are:

- ER70S-2 has added deoxidizers (Titanium, Zirconium & Aluminum) while ER70S-2 relies on Silicon and Manganese as deoxidizers.

- ER70S-2 provides high weld metal toughness compared to ER70S-6 although both have the same minimum specified toughness properties.

- ER70S-2 can be used for rusty and dirty material surfaces easily while ER70S-6 will not give good weldability on rusty-dirty surfaces.

Click here to learn the Differences Between ER70S-2 & ER70S-6 in depth.

ER70S-2 Vs ER70S-3

Both ER70S-2 and ER70S-3 are mild steel TIG Welding Filler Wire Rods. The main differences between the ER70S-2 & ER70S-3 are:

- ER70S-2 has added deoxidizers (Titanium, Zirconium & Aluminum) while ER70S-3 relies on Silicon and Manganese as deoxidizers.

- ER70S-2 provides high weld metal toughness (20 ft·lbf @ –20°F) compared to ER70S-3 (20 ft·lbf @ –0°F).

- ER70S-2 can be used for rusty and dirty material surface easily while ER70S-6 will not give good weldability on rusty-dirty surfaces.

Click here to learn the Differences Between ER70S-2 & ER70S-3 in depth.

ER80S-D2 Vs ER70S-2

ER80S-2 is a Low Alloy Steel (High Manganese-Molybdenum) TIG MIG Filler wire as per AWS A5.28 Specification while ER70S-2 is a Carbon Steel welding filler wire.

The Tensile Strength of ER80S-2 is 80Ksi while for ER70S-2 is 70Ksi. Both ER80S-D2 and ER70S-2 have the same toughness properties of 27 J at –30°C (20 ft·lbf @ –20°F) in as welded condition (No PWHT).