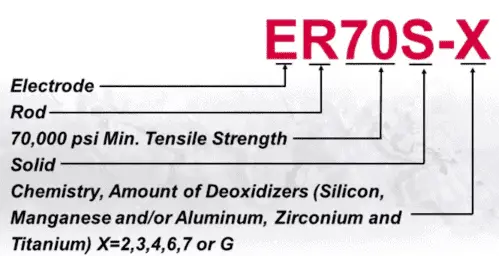

Both ER70S-2 and ER70S-6 are carbon steel TIG or MIG solid filler wires supplied as per the AWS A 5.18 or SFA 5.18 (Welding electrode specification) covered in ASME Section II C. SFA 5.18 is the Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding.

ER70S-6 vs. ER70S-2 (Difference based on chemistry)

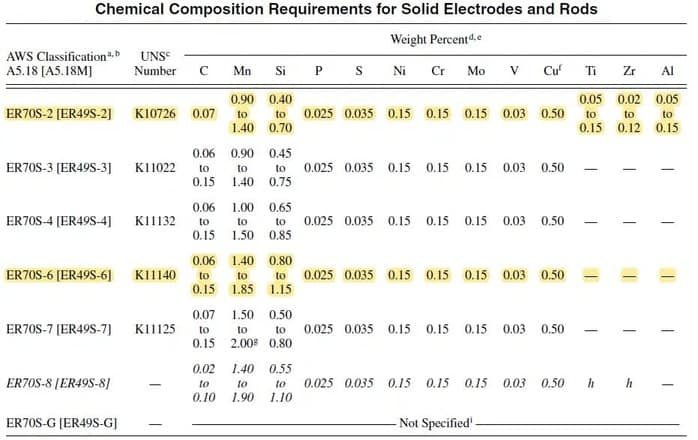

The table below shows the chemical properties of ER70S-6 and ER70S-2. As you can see ER70S-2 contains 3 deoxidizers (Ti, Zr, and Al) along with Si and Mn while the ER70S-6 only contain Silicon and Manganese to perform the deoxidation in the weldment. Silicon is also responsible to provide fluidity to the weld during solidification.

| Element | ER70S-2 | ER70S-6 |

|---|---|---|

| Carbon | 0.07 Max. | 0.06- 0.15 |

| Manganese | 0.90- 1.40 | 1.40- 1.85 |

| Silicon | 0.40- 0.70 | 0.80- 1.15 |

| Chromium |

0.15 Max. |

0.15 Max. |

| Moly | 0.15 Max. | 0.15 Max. |

| Sulfur | 0.035 Max | 0.035 Max |

| Phosphorus | 0.025 Max | 0.025 Max |

| Nickel | 0.15 Max. | 0.15 Max. |

| Vanadium | 0.03 Max. | 0.03 Max. |

| Copper | 0.50 Max. | 0.50 Max. |

| Titanium | 0.05- 0.15 | Nil |

| Zirconium | 0.02- 0.12 | Nil |

| Aluminum | 0.05- 0.15 | Nil |

What is the difference between ER70S-2 (ER49S-2) and ER70S-3 (ER49S-3)?

Due to triple deoxidizers presents in the filler wire, ER70S-2 is much suited to weld on rusted surfaces compare to ER70S-6.

Rust which is basically iron oxide will react very fast with Ti, Zr, or Al to form their oxides such as TiO2 or ZrO2 or Al2O3 thus the precious Mn will be saved.

You must know that Mn provides strength as well as toughness to the weldment. So, any loss of Mn from the weld deposit will actually reduce the strength of the weld metal.

Loss of silicon will make the weld pool sluggish and can result in a poor weld bead appearance.

Welding Electrode/ Filler wire/ Filler metal Selection Chart

ER70S-6 vs. ER70S-2 (Difference based on mechanical properties)

ER70S-6 welding wire MTC, specification, chemical-mechanical properties

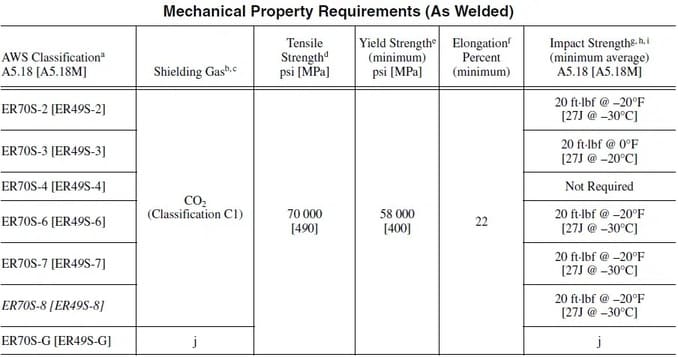

There is no difference between ER70S-6 and ER70S-2 based on mechanical properties as both have 70ksi Tensile strength and 58 Ksi Yield strength.

| Property | ER70S-2 | ER70S-6 |

|---|---|---|

| Tensile Strength | 70 Ksi (490 MPa) | 70 Ksi (490 MPa) |

| Yield Strength | 58 Ksi (400 MPa) |

58 Ksi (400 MPa) |

| Elongation % | 22% min. | 22% min. |

| Toughness |

27 Joules @-30°C |

27 Joules @-30°C |

| Specification | AWS A5.18 | AWS A5.18 |

Both the wire provides equal minimum specified tensile strength, yield strength, ductility, and toughness values. The table below shows the mechanical properties of both wires.

What is ASME F-Number for filler metals?

ER70S-6 vs. ER70S-3

Both Er70S-6 and ER70S-3 are solid wires used for TIG and MIG-MAG Welding of Carbon steel/ mild steel material.

The main difference between the percentage of Manganese and Silicon. ER70S-3 contains a lower amount of Mn and Si compared to ER70S-6.

Refer to the tables given above for the chemical percentage of alloying elements in ER70S-3 or ER70S-6.

| Element | ER70S-3 | ER70S-6 |

|---|---|---|

| Carbon | 0.06- 0.15 | 0.06- 0.15 |

| Manganese | 0.90- 1.40 | 1.40- 1.85 |

| Silicon | 0.45- 0.75 | 0.80- 1.15 |

| Chromium |

0.15 Max. |

0.15 Max. |

| Moly | 0.15 Max. | 0.15 Max. |

| Sulfur | 0.035 Max | 0.035 Max |

| Phosphorus | 0.025 Max | 0.025 Max |

| Nickel | 0.15 Max. | 0.15 Max. |

| Vanadium | 0.03 Max. | 0.03 Max. |

| Copper | 0.50 Max. | 0.50 Max. |

ER70S-6 TIG rod welding

If you’re a welder, then you know that having the right tools is essential to the quality of your work. And when it comes to TIG welding, using the right rod is key to getting a strong, consistent weld.

Read More: ER70S-6 Welding Rod Properties

ER70S-6 TIG rods are some of the most popular welding rods available, and for good reason. They offer excellent weldability and produce strong, high-quality welds. Plus, they’re compatible with a wide range of metals, making them perfect for a variety of welding applications.

ER70S-6 is a solid TIG rod that is used for general purpose welding. It can be used on mild steel, carbon steel and low alloy steel.

It produces high quality welds with excellent mechanical properties. The welds are of good quality finish.

This rod provides good wetting action and produces a smooth, uniform bead. It is also easy to start and maintain an arc with this rod.