E309L-16 Welding Rod

E309L-16 Specification is an austenitic, chromium-nickel stainless steel welding rod used for dissimilar welding applications.

E309L-16 rod is used for welding austenitic stainless steels to other stainless-steel types. It is also used for welding of stainless steel to low alloy steel, carbon steel, mild steel and cast Steel.

E309L-16 Specification

AWS A5.4 covers the classification of E309L-16 electrodes. AWS A5.4 covers this E309L-15 chemical, mechanical and delivery conditions.

- Specification: AWS A5.4

- Classification: E316L-16 (E316L-XX)

- Welding Process: Shielded Metal Arc Welding (Stick Welding)

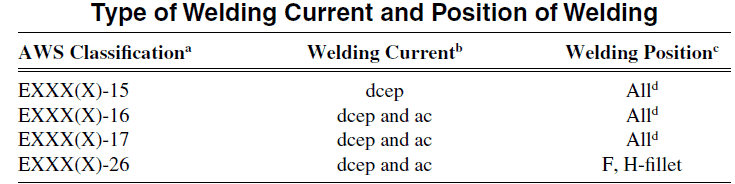

- Welding Polarity: DCEP and AC

- Welding Positions: All

- Standard Diameters Availability: 3/32’’, 1/8’’, 5/32’’, 3/16’’

E309L-16 chemical properties

E309L-16 is a low carbon, high chromium stainless steel. The chemical composition of E309L-16 are listed in below table:

| Element | %age |

|---|---|

| Carbon | 0.04 Max. |

| Chromium | 22.0- 25.0 |

| Nickel | 12.0 -14.0 |

| Molybdenum | 0.75 Max. |

| Manganese | 0.5- 2.5 |

| Silicon | 1.0 Max |

| Copper | 0.75 Max |

| Sulfur | 0.03 Max |

| Phosphorus | 0.04 Max |

E309L-16 Mechanical Properties

The mechanical properties of E309L-16 as per AWS A5.4 are listed in the below table:

| Property | E309L |

|---|---|

| Tensile Strength Ksi (MPa) | 75 (520) |

| Yield Strength Ksi (MPa) | Not specified |

| Elongation minimum % | 30 |

| Heat treatment | None |

E309 & E309-L F Number

F-Number for E309 and E309L as per ASME Section IX is F-Number: 4.

E309L-16 Meaning

E309L-16 is a Stainless Steel Welding Rod with low carbon content used for dissimilar welding applications such as welding of SS304 to Carbon steel.

E309L is also used to weld a barrier layer on carbon steel when cladding or surfacing with an E308L welding rod.

E309L welding rod has high resistance to intergranular corrosion and weld deposit with higher ferrite compared to other stainless steel welding rods.

E309L-16 Welding Rod amperage

E309L-16 welding rod amperage should be between 70 and 110 amps for a 1/8” rod. Higher-diameter rods need higher welding amperage.

The welding parameter range given in the below table will provide the necessary welding heat when using E309L-16.

| Rod Dia. | Amperage | Voltage |

|---|---|---|

| 3/32 inches | 60- 80 | 23- 28 |

| 1/8 inches | 75 -95 | 25- 30 |

| 5/32 inches | 100- 140 | 27- 32 |

| 3/16 inches | 110- 150 | 27- 32 |

Further, When it comes to E309L-16 welding rod amperage, there are a few things you need to know. First, this type of welding rod is best used with a DCEP and AC power source.

Second, you’ll need to use a lower amperage setting when using this type of welding rod for thin sheet metal and a smaller diameter rod.

Third, be sure to use the correct welding voltage. fourth, always use fresh rods, damaged rods must be discarded. Fifth, keep your torch at the correct angle to have a uniform bead appearance.

Sixth, don’t overheat the area you’re welding, thus can cause burn-through. Seventh, make sure you have good ventilation. Eighth, practice makes perfect!

E309L-16 Welding Rod Polarity

E309L-16 Welding rod can be used with AC & DCEP Polarity. They can be used successfully with Reverse polarity (Electrode positive) on Stick Welder.

Welding with DCEN polarity results in an unstable arc and hence welding with straight polarity using E309L-16 is not advised.

Related reading: Types of polarity in SMAW, MIG, MAG, FCAW, TIG and SAW

E309L-16 Welding Rod uses

The E309L-16 Welding Rod can be used for a variety of applications including:

1. Joining Dissimilar Metals: The E309L-16 Welding Rod can be used to join dissimilar metals together. This includes joining stainless steel to mild steel or nickel alloys to stainless steel.

2. Repairing damaged metal: The E309L-16 Welding Rod can be used to repair damaged metal.

3. To weld stainless steel to carbon steel: When joining these two metals together, it is important to use a low-carbon steel welding rod like E309L-16 in order to prevent corrosion at the joint.

4. Welding of Duplex Stainless steel to Carbon Steel to low alloy steel.

E309L-16 vs E309L-17 welding Rod

When it comes down to E309L-16 vs E309L-17, which is the better choice? Which one you should use for your job?

Below are the points explaining E309L-16 vs E309L-17 welding Rod differences:

Read more: Difference between E309L-15, 16 17, E316L-15,16 and 17

Both E309L-16 & E309L-17 has same mechanical and chemical properties. The difference is between their usability characteristics. These differences are given in the below table:

E309L-16 is a Titania covering electrode that is good for welding with AC and DCEP polarity. It can be used on carbon steel, low alloy steel, and stainless steel.

E309L-17 has a silica-titania coating, which makes it useable for AC & DCEP polarity too. It can also be used on carbon steel and low alloy steel welding to stainless steel welding.

So, which one should you choose? If you’re doing general purpose welding, then E309L-16 is a good choice..

E309 vs E309L

Both E309 and E309L are Stainless Steel welding rods as per AWS A5.4 specification. E309L is a low carbon variant that is useful to prevent Intergranular corrosion in the weldment.

E309 is a high carbon version having a high carbon content of up to 0.15% instead of the 0.04% maximum limited for E309L type rod.

All other chemical compositions are the same for both rods (E309L & E309) as given in the below table.

| Element | E309L | E309 |

|---|---|---|

| Carbon | 0.04 Max. | 0.15 Max. |

| Chromium | 22.0- 25.0 | 22.0- 25.0 |

| Nickel | 12.0 -14.0 | 12.0 -14.0 |

| Molybdenum | 0.75 Max. | 0.75 Max. |

| Manganese | 0.5- 2.5 | 0.5- 2.5 |

| Silicon | 1.0 Max | 1.0 Max |

| Copper | 0.75 Max | 0.75 Max |

| Sulfur | 0.03 Max | 0.03 Max |

| Phosphorus | 0.04 Max | 0.04 Max |

E309 has high tensile and Yield strength compared to E309L as shown in the below table. Both 309 and E309L have the same percentage elongation.

Yield Strength for AWS A5.4 specification welding rods is not specified as this can change depending on the heat input during welding.

| Property | E309L | E309 |

|---|---|---|

| Tensile Strength Ksi (MPa) | 75 (520) | 80 (550) |

| Yield Strength Ksi (MPa) | Not specified | Not specified |

| Elongation minimum % | 30 | 30 |

| Heat treatment | None | None |

What is the difference between 308 and 309 welding rod?

Both 309 and 308 are stainless steel welding rods as per AWS A5.4 specification. 308 welding rod is used for welding austenitic stainless steel to austenitic stainless steel only, such as welding of SS304 to SS304.

While 309 welding rod is used for dissimilar welding applications. E.g., welding of SS304 to carbon steel or low alloy steel material.

Compared to 308, 309 welding rod contains high chromium and Nickel, making it beneficial for welding stainless steel to mild steel material while ensuring a high amount of chromium and nickel is present in the weldment even after weld dilution between carbon steel and stainless steel materials.