What is AISI 304 & 304L/ 304L Material?

This articles cover in depth information about the Welding of 304 (18-8 Stainless Steel) Stainless Steel. Before we go to welding part, let us first get the important information about 304 steel.

AISI 304 (18-8 Stainless Steel) stainless steel is the most common form of stainless steel used for welding constructions around the world, largely due to its excellent corrosion resistance and value.

It contains between 16 and 18% percent chromium and 8-12% nickel, as well as small amounts of carbon, silicon and manganese. The balance of the chemistry is iron.

AISI 304 stainless steel is commonly known as 18-8 Stainless Steel.

Read more: AISI 304 Stainless Steel (18-8 stainless steel): The Facts You Need to Know

Material Specification for SS304 Stainless Steel

The UNS Number of AISI 304 (18-8 stainless steel) is UNS S30400. Similarly, the UNS Number of AISI 304L is S30403. Various material specification and their product forms for AISI 304 is covered in below table:

| Material Specification | Type of material form |

| ASTM A 213 | Seamless Tubes |

| ASTM A 249 | Welded Tubes |

| ASTM A 312, A409 | Welded Pipes |

| ASTM A 358 | EFW Pipes |

| ASTM A 376 | Seamless Pipes |

| EN 10088-2 | X5CrNi18-10, (EN 1.4301) |

ASME Section IX Welding P Number of AISI 304/ 304L (18-8 Stainless Steel): ‘8’

ASME Section IX Welding Group Number of AISI 304/ 304L (18-8 Stainless Steel): ‘1’

Chemical & Mechanical Properties of AISI 304 (18-8 Stainless Steel)

Chemical and mechanical properties of AISI 304 (18-8 Stainless Steel) are covered in the below table:

| Grade | 304 | 304L |

| Element | Weight % | Weight % |

| Carbon | 0.07 | 0.030 |

| Manganese | 2.00 | 2.00 |

| Silicon | 0.75 | 0.75 |

| Chromium | 17.5 -19.5 | 17.5 -19.5 |

| Nickel | 8- 10.5 | 8- 12 |

| Molybdenum | 0 | 0 |

| Nitrogen | 0.10 | 0.10 |

| Sulfur | 0.30 | 0.30 |

| Phosphorus | 0.045 | 0.045 |

| Grade | AISI 304 | AISI 304L |

| Yield Strength, Minimum | 30 Ksi (205 MPa) | 25 Ksi (170 MPa) |

| Tensile Strength, Minimum | 75 Ksi (515 MPa) | 70 Ksi (485 MPa) |

| Elongation, min% | 40 | 40 |

| Hardness, Maximum | 92HRBW/ 201 HBW | 92HRBW/ 201 HBW |

| Thermal Conductivity | 21.5 W/m·K @ 500 °C/ 932 °F | 21.5 W/m·K @ 500 °C/ 932 °F |

| Thermal Expansion | 17.3 µm/m/°C | 17.3 µm/m/°C |

| Density | 7.9 g/cm3 | 7.9 g/cm3 |

| Modulus of Elasticity | 193 GPa | 193 GPa |

| Melting Temperature | 2550 to 2651 °F (1400 to 1455 °C) | 2550 to 2651 °F (1400 to 1455 °C) |

Welding of 304 (18-8 Stainless Steel) Steel

This AISI 304 (18-8 Stainless Steel) grade can be welded using TIG, MIG, and Stick welding.

It is important to note that when welding this material it is important to use a filler metal that matches the composition of the base material. Failure to do so can result in welds that are weaker than the base material itself.

This article covers the Stick Welding (SMAW), TIG welding and MIG welding of AISI 304 (18-8 Stainless Steel) material.

Stick Welding of 304 (18-8 Stainless Steel)

E308L-15, E308L-16, and E308L-17 (AWS A5.4 Specification) types of welding electrodes are used for stick welding (SMAW) AISI 304 or also 18-8 stainless steel.

Read more: Difference between E309L-15, 16 17, E316L-15,16 and 17

These electrodes have a low carbon content, which helps to prevent intergranular corrosion of the weld metal.

AISI 304L (18-8 stainless steel) Stick welding (SMAW) is used with DCEP welding polarity.

TIG Welding of 304 (18-8 Stainless Steel)

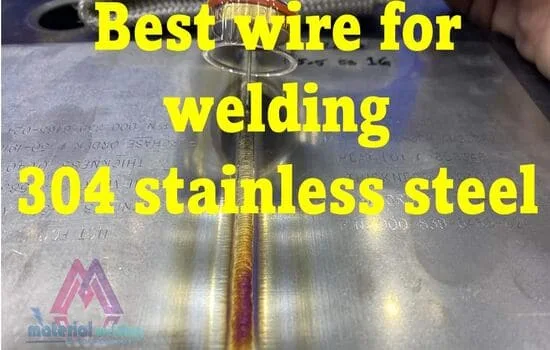

TIG welding of AISI 304 or 18-8 stainless steel is carried out with ER308L (AWS A5.9) type filler wire rod. Pure argon or mixture of argon + Oxygen is used for shielding and purging during welding.

Trailing gas is not required for Stainless steel welding such as AISI 304.

AISI 304L (18-8 stainless steel) TIG welding is used with DCEN welding polarity.

MIG Welding of 304 (18-8 Stainless Steel)

MIG welding (GMAW) of AISI 304 or 18-8 stainless steel is carried out with ER308L (AWS A5.9) type filler wire rod.

Pure argon or mixture of argon + Oxygen is used for shielding and purging during AISI 304 (18-8 stainless steel ) welding.

Trailing gas is not required for Stainless steel welding such as AISI 304. AISI 304L (18-8 stainless steel) MIG welding is used with DCEP welding polarity.

Flux Cored Arc Welding (FCAW) of AISI 304 (18-8 Stainless Steel)

ER308L FCAW Welding wire rod equivalent is E308T0-3 or E308LT0-3.

FCAW welding of AISI 304 or 18-8 stainless steel is carried out with E308T0-3 or E308LT0-3 (AWS A5.22) type flux cored wire rod.

E308T0-3 or E308LT0-3 are self shielded FCAW wire and not require any external shielding gas. E308T1-1 is used with Pure Co2 as welding shielding gas.

Welding polarity for E308T1-1, E308T0-3 or E308LT0-3 is DCEP.

Welding of S304 (18-8 Stainless Steel) with SS316

Stick Welding (SMAW) of S304 (18-8 Stainless Steel) with SS316 is carried out using E308LMo-16 type welding rod. E308LMo contains molybdenum that is an essential element of SS316 material.

TIG and MIG welding of S304 (18-8 Stainless Steel) with SS316 is carried out using ER308LMo type filler wire.

Flux Cored arc welding of S304 (18-8 Stainless Steel) with SS316 is carried out using E308LMoTX-X type flux cored wire.

Welding of 304 (18-8 Stainless Steel) Stainless Steel to Mild Steel

TIG and MIG Welding of 304 (18-8 Stainless Steel) Stainless Steel to Mild Steel is carried out using ER309L.

Stick Welding (SMAW) of 304 (18-8 Stainless Steel) Stainless Steel to Mild Steel is carried out using E309L-15/16/17. Welding polarity is kept as DCEP (Reverse polarity).

Welding Rod for 304 (18-8 Stainless Steel) Stainless Steel

Welding Rods for Welding of 304 (18-8 Stainless Steel) Stainless Steel are:

- E308L-15, E308L-16, E308L-17 (For Stick Welding)

- ER308L, ER308LSi (For TIG and MIG Welding)

- 308T1-1, E308T0-3 or E308LT0-3 (For FCAW)

Welding 304 (18-8 Stainless Steel) Stainless Steel with 316 Filler Rod

Welding of 304 (18-8 Stainless Steel) Stainless Steel with 316 (E.g., E316L-15 or ER316L) Filler Rod can be done if E308L/ER308L is not available.

Welding with ER316L will result in higher molybdenum in the weldment with high ferrite but increase corrosion resistant of the weld compared to base metal.

If, this is acceptable for service point of view, welding of 304 can be done with 316 filler wire rod.

Welding 304 (18-8 Stainless Steel) Stainless steel to 409 Stainless Steel

Welding of 304 (18-8 Stainless Steel) Stainless steel to 409 Stainless Steel is carried out using E309L-15 or ENiCrFe-2 or -3 or ENiCrMo-3 or their equivalent TIG and MIG Filler wire rods.

Can you Weld 18-8 Stainless steel to 304 Stainless Steel?

First, you must know that 18-8 Stainless steel or 304 Stainless Steel are same material. 18-8 is another name for 304 stainless steel.

So, if you want to weld 18-8 Stainless steel to 304 Stainless Steel, you can do using E308L-15, ER308L, or 308T1-1, E308T0-3 or E308LT0-3 type welding wires.

Why Welding of Stainless Steel is difficult?

Welding of Stainless Steel is difficult because of its low thermal conductivity. The heat from the welding process is retained in the area being welded, making it difficult to control the temperature. The high thermal expansion of stainless steel can also cause distortion during welding.

Stainless Steel is difficult to weld because of its low thermal conductivity. The heat generated during welding is not easily transferred to the surrounding area, which can cause distortion and cracking.

Additionally, Stainless Steel has a high thermal expansion compared to other steels. This means that when heated, it expands more than other materials and can cause warping and other problems.