E308L Welding Rod Meaning

E308L is used for welding AISI 301, SS302, SS304, and SS305 type grades (austenitic stainless steel). It is also used for welding Stainless Steel Casting such as CF8M & CF3M types.

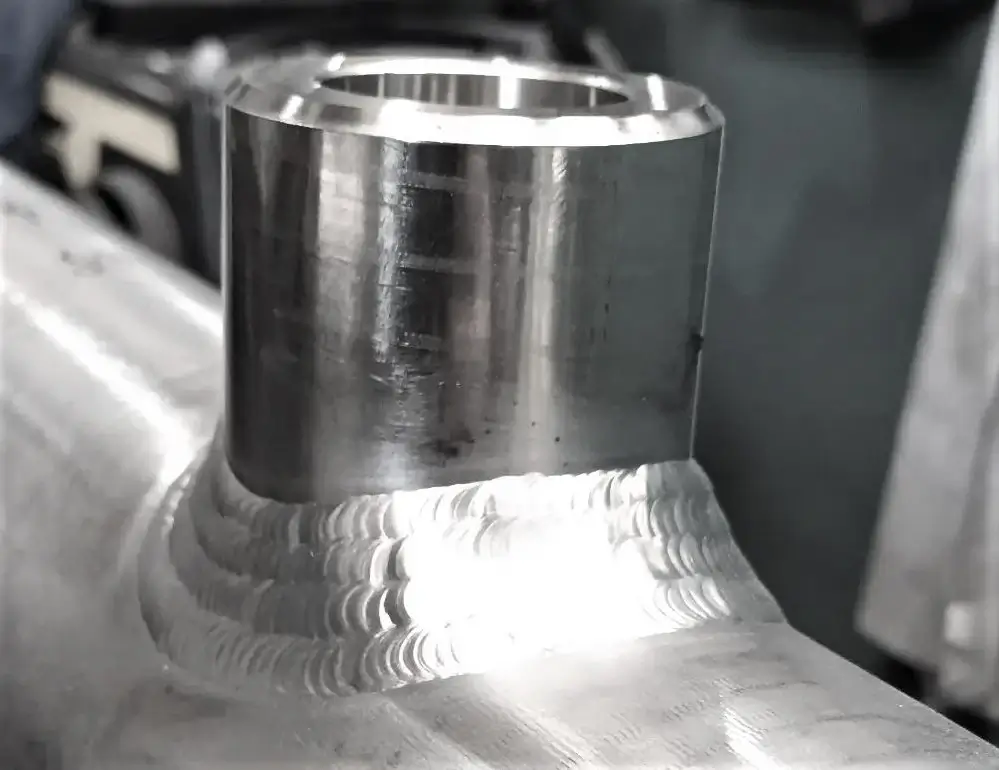

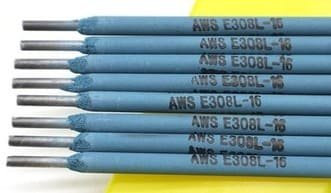

Welding rods are an important part of the welding process, as they provide the filler material that is used to create a weld. The E308L welding rod is a Covered Welding Electrode for Stick Welding (SMAW). E308L rod is a versatile option that can be used for welding different Stainless Steel Grades.

It has a low-carbon content. The rod also has a high resistance to cracking and offers good weldability.

E308L Rods have the following classification variants as per AWS A 5.4 Specification:

- E308: Standard type

- E308L: Low Carbon version

- E308H: High Carbon version

- E308Mo: With added molybdenum & high carbon

- E308LMo: With added molybdenum & low carbon

E308L Welding Rod Specification

The AWS Specification for E308L and other E308L variants as given above is AWS A5.4. AWS A5.4 covers stick welding electrodes for stainless steel welding applications.

You can find chemical, mechanical & technological properties of stainless Welding electrodes in this specification.

A-Number for E308L

A-Number for E308L as per ASME Section IX is A-Number 8. This weld deposit chemistry is a Chromium-Nickel base deposit.

E308L Chemical & Mechanical Properties

E308L is a low carbon Stick Welding Electrode for Stainless Steel Welding applications. The Chemical composition of E308L as per AWS A5.4 electrode specifications is given in the below table:

| Element | Weight Percent% |

| Carbon | 0.08 Max. |

| Chromium | 18.0- 21.0 |

| Nickel | 9.0- 11.0 |

| Molybdenum | .075 Max. |

| Manganese | 0.5- 2.5 |

| Silicon | 1.0 Max |

| Phosphorous | 0.04 Max. |

| Sulfur | 0.03 Max. |

| Copper | 0.75 Max. |

Being an austenitic weld deposit, E308L Welding Rod gives a weld of high tensile strength. As per AWS A5.4, the welding rod shall have the following mechanical properties:

- Minimum Tensile Strength: 75 Ksi (520 MPa)

- Elongation minimum: 30%

There are no requirements for Yield Strength as it can be affected due to the welding heat input. Also, there are no toughness requirements for E308L-type welding rods.

E308L-15 Welding Electrode

E308L-15 is a Basic Coating Stick Welding Electrode for Welding Stainless Steel Material. E308L is used for welding of AISI 301, SS302, SS304, and SS305 type grades.

E308L-16 Welding Electrode

E308L-16 type welding rod with 16 number at the end has titania based or rutile type covering on rod. These welding rod are used with AC & DCEP polarity both.

In terms of mechanical properties, both E308L-15 or E308L-16 or E308L-17 are having same tensile strength, yield strength and percentage elongation.

Due to readily ionizing elements, such as potassium, E308L-16 can be easily used to provide a stable welding arc with alternating current (AC polarity).

E308L-17 Welding Electrode

E308L-17 type welding rod has a silica-titania covering. This coating is a modified version of a E308L-16 rod, where small amount of titania is replaced with silica coating. The characteristics of E308L-17 welding rods are:

- E308L-17 rod is used with DCEP (direct current electrode positive) & AC welding polarity.

- Silicon present in the electrode increases the fluidity of weld puddle. That is beneficial for stainless steel welds which are usually have low fluidity (sluggish) in the weld puddle.

- E308L-17 designation electrodes produces flat weld bead compare to -15 & -16 types rods.

- Welding in vertical uphill progression need more weaving during welding due to slow freezing slag in E308L-17 electrodes.

E308L-16 Welding Rod Amperage

In welding, the amperage is the measure of the amount of electricity flowing through the welding rod.

The E308L welding rod has a recommended amperage range of 70-160 amps. The lower end of the range is best for thin metals, while the higher end is better for thicker metals.

- Use 70- 90 ampere for 3/32” Stick Welding Rod.

- 80- 110 ampere for 1/8” Stick Welding Rod.

- 115- 140 ampere for 5/32” Stick Welding Rod.

- 1115- 160 ampere for 3/16” Stick Welding Rod.

Setting the welder too high will cause the metal to melt too quickly, leading to poor welds. Conversely, setting it too low will result in a slow weld that may not be a good weld fusion.

E308L-16 Welding Rod Polarity

E308L-16 Welding electrode can be used with both AC & DCEP Welding Polarity. E308L-15 type welding rod can only be used with DCEP Welding polarity.

E308L-17 & or E308L-26 classification rod can also be used with AC & DCEP Polarity. Here, -15, -16, -17, -26 is the usability characteristic of these welding rods. Click here to learn in detail the meaning of this usability characteristic of welding electrodes.

E308L welding Rod uses

The E308L welding rod is a popular choice among welders for its versatility and ability to create high-quality welds. This rod can be used on a variety of materials, including carbon steel, stainless steel, and aluminum.

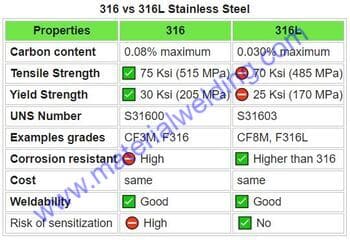

E308L is used for welding of AISI 301, SS302, SS304, and SS305 type grades. E308H is used for welding of AISI 304H grade. Similarly, E308M is used for welding ASTM CF8M Stainless steel casting & can also be used for welding of 316 stainless steel grade.

E308LMo rod is used for welding ASTM CF3M & 316L stainless steel casting & other materials respectively.

E308L MTC (Test Certificate)

You can download actual MTC for E308L-16 type Welding Rod via this link.