ASTM A743 CA6NM Material

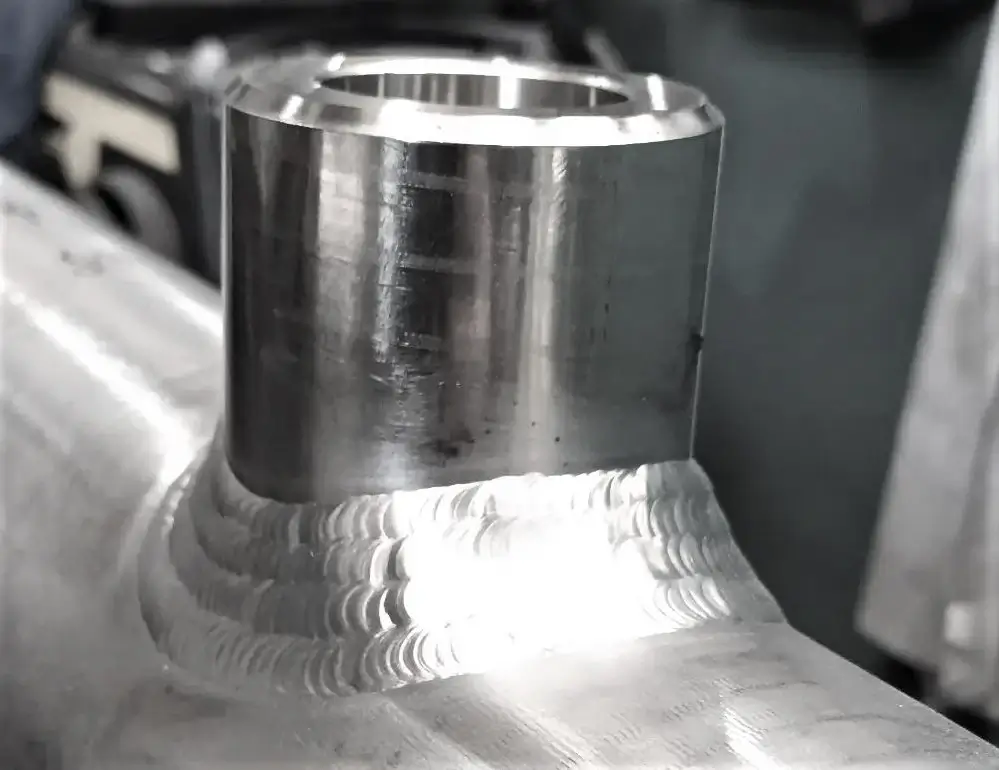

CA6NM or E3N is a 400 series Martensitic stainless steel having UNS Number J91540 used in the casting form. CA6NM offers good corrosion resistance and high tensile strength making it an ideal alloy for turbines parts, aerospace applications, and pumps- valves parts.

The wrought form material grade is F6NM with UNS number S41500. The material delivery conditions are generally Normalized & tempered and Q & T. This makes this alloy suitable for pressure parts applications.

P No., Group No. for CA6NM

The P number of CA6NM as per ASME Section IX is P-6, Group 4. The UNS Number for CA6NM material is J91540.

Material Specifications

CA6NM material is supplied according to the below specifications:

ASTM Specifications: ASTM A352, A487, A743, and A757. ASTM A352 and A487 are pressure-grade materials and are listed in the ASME Section IX.

DIN equivalent material for CA6NM is DIN 1.4313 (G-X5CrNi13-4).

Chemical and Mechanical Properties of CA6NM

Chemical requirements for CA6NM are shown in the below table.

| Alloying element | Wt. in percentage |

| C | 0,06 |

| Cr | 11,5 to14,0 |

| Mn | 1,0 |

| Mo | 0,4 to 1,0 |

| Ni | 3,5 to 4,5 |

| P | 0,04 |

| Si | 1 |

| S | 0,03 |

The minimum Yield strength of the CA6NM is 80 Ksi (550MPa) and Tensile Strength is 110 Ksi (760 MPa) with an elongation of 15%. The maximum permitted hardness for base material is 23 HRC or 255 HB.

CA6NM Stick welding (SMAW) electrode

Stick Welding or SMAW welding of CA6NM to be carried out using an E410NiMo-15/16 type welding electrode at ambient temperature.

TIG or MIG welding of CA6NM can be carried out with ER410NiMo type filler wire at ambient temperature.

It is often desirable to weld martensitic stainless steels with matching or near-matching filler metals in order to match the strength of the base metal.

Preheat and Postheat for CA6NM Material

A minimum preheat temperature of 50 °F (10°C) shall be applied before the welding and to be maintained throughout the welding operation.

For heavy casting preheat the base metal in the range of 210 to 280°F (100 °C to 140°C). The interpass temperature shall be controlled to a maximum of 650 °F (345 °C) during the welding.

Being a martensitic alloy, CA6NM is air hardenable, and control of preheating and interpass temperature is very important.

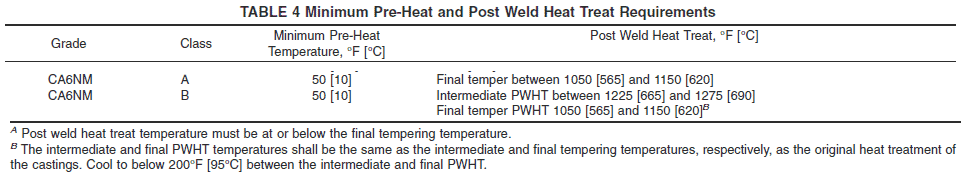

CA66NM post weld heat treatment

The PWHT temperature for CA6NM after welding shall be as given in the below table, referenced from ASTM A487.

First heat treatment (intermediate PWHT) at a temperature of 1225 °F to 1275 °F. After this material is air-cooled at ambient temperature.

The second PWHT is carried out at a temperature of 1100 °F to 1150 °F and then air cooling to ambient temperature.

ASTM CA6NM Heat treatment

Double tempering heat treatment is needed for CA6NM alloy. To perform the double tempering, the material is first heated at a temperature of 1225 °F to 1275 °F and then air-cooled at the ambient temperature.

The second tempering is carried out at a temperature of 1100 °F to 1150 °F followed by air cooling to provide the best tempering to the material.

CA6NM vs 316 SS

CA6NM or E3N is a 400 series Martensitic stainless steel while the 316 is austenitic stainless steel.

CA6NM is air hardenable while 316L being austenitic is not air hardenable. 316 offers high corrosion resistance including pitting resistance while CA6NM corrosion resistance is not very good compared to 316 types of stainless steel.

CA6NM weld repair

- For performing repairs on casting parts, use a qualified welding procedure as per the ASME Section IX.

- Clean the area, remove the defects completely and verify the defect removal using Penetrant testing.

- Carry out the welding repair using the welding electrode given in this post.

- Perform the penetrant inspection after completion of the repair.