Meaning of E6010 Welding Rod

E6010 stick welding rod is a cellulose-coated rod. The electrode specification is AWS A5.1 & E4310 according to the CSA W48.

E6010 is mainly used for pipeline welding root welds applications as there is no or little slag formation with this rod. Hence, for root run, not much effort is required for cleaning. Another reason is the high force arc of the E6010 rod that ensures full penetration when welding root run.

E6010 is the main stick welding rod used for new welding trainees or journeymen followed by welding training using E7018 types. E6010 electrodes have deep penetrating, high force, spray arc, and easily removable, very thin to negligible friable welding slag. The slag appears not to be completely seen on the weld bead in a visual look.

Fillet welds welded with E6010 usually appear as a flat face with coarse unevenly welded ripples. Using E6010 on capping and fill pass requires maintenance of preheat temperature above 225°F or 100°C to ensure the removal of hydrogen from the weldment.

The cellulose used for making the E6010 rod is an “organic compound” & needs moisture and thus it is the source of hydrogen in the welding.

As we know in welding, Hydrogen is considered to be dangerous as it can cause weld & HAZ cracking but here in E6010 or E6011 electrodes, hydrogen provides a very beneficial effect. It gives the welding arc high force and makes it very concentrated.

Thus, the arc is more powerful and deep penetrating. You can even cut material with these electrodes by using a high current if required in an emergency.

Buy E6010 Stick Rod at the best price

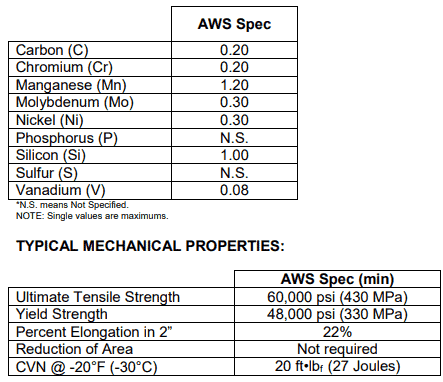

Chemical & mechanical properties of E6010 Rod

E6010 is a mild steel stick welding rod having a tensile strength of 60KSi and a Yield strength of 48KSi. The toughness requirement for E6010 is 27 Joules at -30°C (20 ft•lbf at -20°F).

The detailed chemical & mechanical properties for the E6010 stick welding (SMAW) rod are given in the below table.

Covering type of E6010 Electrode

The coverings of E6010 are primarily highly cellulose type (mostly paper pulp), generally more than 30% of total weight.

Other elements usually added to the coating comprise titanium dioxide (works as an arc stabilizer element), metallic deoxidizers such as ferromanganese, and other elements such as magnesium and/or aluminum silicates (to eliminate the adverse effects of sulfur or oxidation elements in the weld).

Liquid sodium silicate is used as a binder to hold the coating on the bare wire of mild steel.

Due to these rod coating main elements, these rods are usually specified as high-cellulose sodium-type stick electrodes.

During the burning of the coating, the flux coating of E6010 will mainly create hydrogen & carbon dioxide.

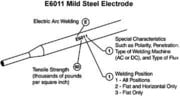

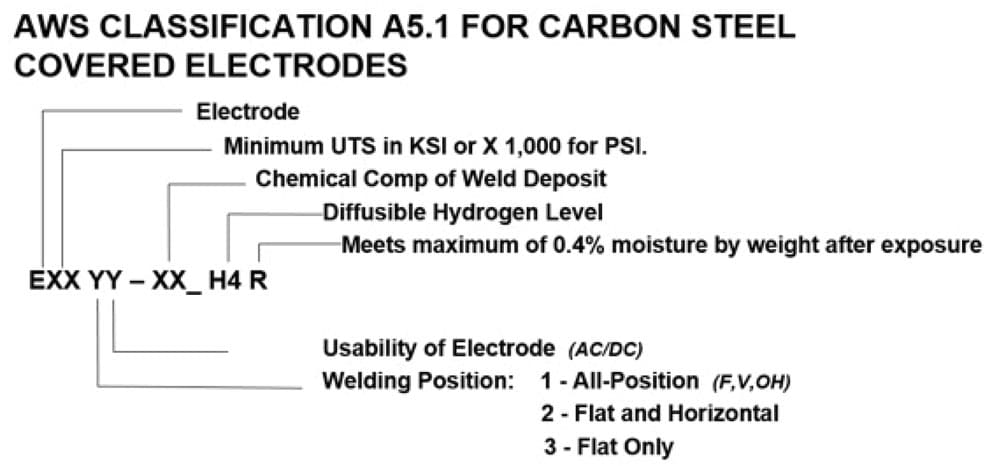

E6010 electrode Specification & classification

E6010 electrodes are classified according to ASME Section IIC, 5.1 Specification for Carbon steel electrodes for Shielded metal arc welding or E4310 as per CSA W48 or SFA 5.1M.

Similar to other welding electrodes, each digit in the E6010 electrode has its own meaning. These digits give very valuable information about this electrode as given below:

- E means SMAW or stick welding electrode.

- The next two digits (6 & 0) 60 state the tensile strength of weld metal, as 60 KSI or 60000 psi.

- The next number 1 means it is all welding position rod which means F, V, OH, and H positions. Where F = Flat, H = Horizontal, H-fillet = Horizontal fillet, V = Vertical and OH means Overhead position.

- The final digit 0 means that it’s a High cellulose sodium-coated rod and can run with DCEP polarity.

Charpy V-Notch Impact (toughness) Requirements for E6010 type electrode

E6010 Stick welding electrode requires to have minimum V-Notch toughness values of 20 ft·lbf at –20°F [27 J at –30°C] as per the AWS A5.1 specification.

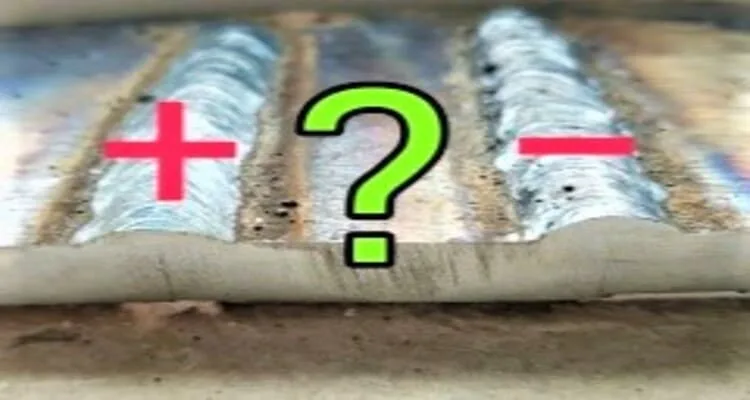

E6010 Welding electrode Polarity

E6010 rod can be used with DCEP (electrode positive) only & designed only for DCEP. Welding with AC or DCEN will result in an unstable arc and poor welding finish for the weld beads.

Click here to Learn Types of Polarity in Welding.

Storage & Baking/ reconditioning of E6010 Electrode

Cellulosic coverings for E6010 (E4310) electrodes need moisture levels of approximately 3% to 7% for proper operation; therefore, storage or conditioning above ambient temperature may dry them too much and adversely affect their operation.

After opening the E6010 electrode packing, store the electrode dry at room temperature and keep it away from the heat source.

Reconditioning is not recommended as it will dry out the essential moisture from the coating which is required to generate hydrogen gases for electrode characteristics.

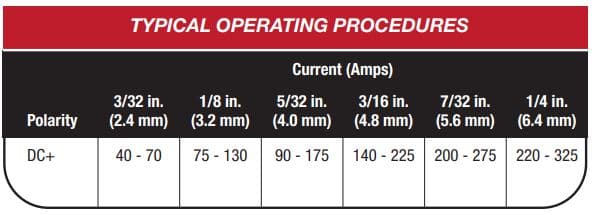

Selection of current for E6010 Electrode

The correct welding amperage (current) setting mainly depends on the electrode diameter used. For example, a 1/8-inch E6010 rod runs well from 70 to 130 amperes, while a 3/16-inch E6010 rod welds at currents up to 225 amperes.

These rods shall be used with DCEP-type (electrode positive) welding polarity. The maximum welding current in ampere that can be used for the large diameter of these rods is limited in comparison to that for other similar classifications because of high spatter material that is lost due to a high welding current setting.

The below table gives the recommended welding amperage for E6010 electrode diameters 3/32, 1/8, 5/32, 3/16, 7/32 & 1/4 inch sizes.

E6010 welding rod uses

- Multipass welding in the vertical uphill/ downhill & overhead welding.

- Welding applications involved pipeline welding (mainly root run & hot pass).

- Good out-of-position welding properties (Both uphill & downhill). Suits well for downhill positions as there is no slag practically with E6010 welding.

- Used in piping, shipbuilding, structure, & other welding applications.

Characteristics of E6010 Type electrode

- All-position is particularly good for vertical and overhead.

- Very little to no slag practically.

- Deep penetration with good dilution.

- Mainly for root run welding.

- Good out-of-position welding characteristics.

E6010 Electrode MTC & Datasheet

Click here to download E6010 MTC and datasheet. The MTC contains the results of the chemical analysis and mechanical strength of the E6010 rod.