Discover the importance of pickling and passivation for stainless steel surfaces. Learn how these processes prevent corrosion and enhance durability. Find expert insights and step-by-step guidelines for effective pickling and passivation techniques.

Pickling and Passivation of Stainless Steel is a chemical surface treatment processes to enhance the corrosion resistance feature of the stainless steel.

Difference between Pickling and Passivation Processes

Pickling and passivation both are chemical treatment processes used for surface treatment of stainless steel after welding or exposure to high temperature to clean the oxides and any other contamination. This assists in the formation of the new chromium oxide layer and thus helps to regain its corrosion resistance that otherwise would be hampered due to oxides & contamination.

Usually picking is followed by passivation treatment for stainless Steel. Passivation does not remove any oxide or contamination but it helps to increase the thickness of the chromium oxide layer in an acidic environment (usually nitric acid or citric acid).

Pickling uses very strong acids such as H2SO4 (Sulfuric acids) and HNO3 (Nitric acid) that remove material from the surface of the material for longer periods while passivation is carried out using HNO3 (Nitric acid) only for short durations.

Pickling vs. Passivation

| Pickling | Passivation |

|---|---|

| Highly aggressive cleaning | Least aggressive & uses weak chemical acids. |

| Rate of material erosion is high & gives deep cleaning | Passivation process does not erode material surface indeed increase the passive layer thickness. |

| Pickling removes dirt’s, grease, oil, & oxides. | Passivation does not remove any surface impurities. |

| Pickling is the first process for cleaning. | Passivation is generally carried out after pickling |

What is Pickling?

Pickling is a chemical treatment process for the removal of scales such as oxides from stainless steel material by immersion in a liquid containing sulfuric acid or hydrochloric acid.

It is used to remove any high-temperature scale/ oxides & nearby low chrome from steel surface by the chemical application after welding.

Pickling is an efficient process for the removal of scale, dirt, and oxides from materials. The scale that is removed results from hot forming, welding, or heat treating operations and from corrosion.

Stainless Steel Pickling

Pickling is a process that uses acid to remove the rust and scale from the surface of stainless steel.

The pickling process can be done in a tank or vat, or it can be done by immersing the stainless steel in a bath of acid. The most common acids used for pickling are hydrochloric acid and sulfuric acid.

Hydrochloric and sulfuric acids are commonly used for ferrous surfaces. Hydrochloric acid, which attacks metal rapidly, is used cold. Sulfuric acid, with a slower rate of attack, is heated.

Phosphoric acid, the slowest acting of all types, is used where it is important to obtain a steel surface free from carbonaceous smut.

A properly controlled pickling bath is much more efficient for scale and rust removal than mechanical abrasion. However, pickling must be followed by a thorough rinsing and neutralizing.

Hydrochloric and sulfuric acids, unless thoroughly removed, can cause organic finishing difficulties.

Pickling is used for which Materials & Metals?

Pickling is applicable to sheet, sand, and die-cast aluminum and its alloys; copper and its alloys; iron and steel; stainless steel; magnesium and its alloys; and nickel and its alloys.

Pickling paste is used for welding areas on larger parts where it is not practical to immerse the parts in the pickling solution. For smaller parts, pickling using immersion tanks is the best method.

Why do We need to do Pickling & Passivation for Stainless Steel?

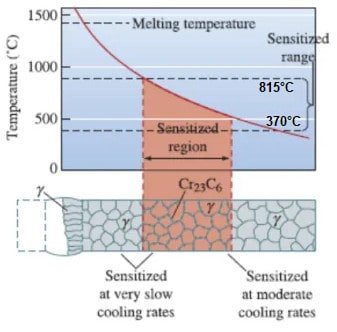

Stainless steel due to the thermal effect of the welding results in the formation of temper colors on the surface by depleting the chromium oxide layer. These areas are prone to corrosion due to the lost Cr-oxide protective layer.

To enhance the natural corrosion resistance and clean the surface of stainless steel material from free iron, oxide, and other contaminations- picking & passivation processes are used.

When welding stainless steel, the heated welded areas are oxidized by the oxygen in the air. This destroys the sensitive passive layer that protects the steel from corrosion.

The material is then no longer corrosion-resistant in these areas and is particularly susceptible to pitting.

If accessible, the oxide layers, also known as temper colors, can be removed by brushing or pickling to restore the corrosion properties.

Another possibility is to protect the welded seam areas from oxygen with inert shielding gases.

Displacing the air and flushing the root area is called purging. During cooling, flushing with the backing gas must be carried out until no further reaction with the air can take place.

In this way, you can easily succeed in forming stainless steel, for example. the formation of pipes and pipelines also works.

What are the Pickling Methods for Stainless Steel & Aluminum?

The main type of pickling methods are:

- Tank immersion pickling treatment- Gives uniform & maximum corrosion protection

- Spray pickling treatment- for special application. require trained personnel due to safety reasons.

- Circulation pickling treatment- Useful for pipe internals treatment

What is Passivation of Stainless Steel?

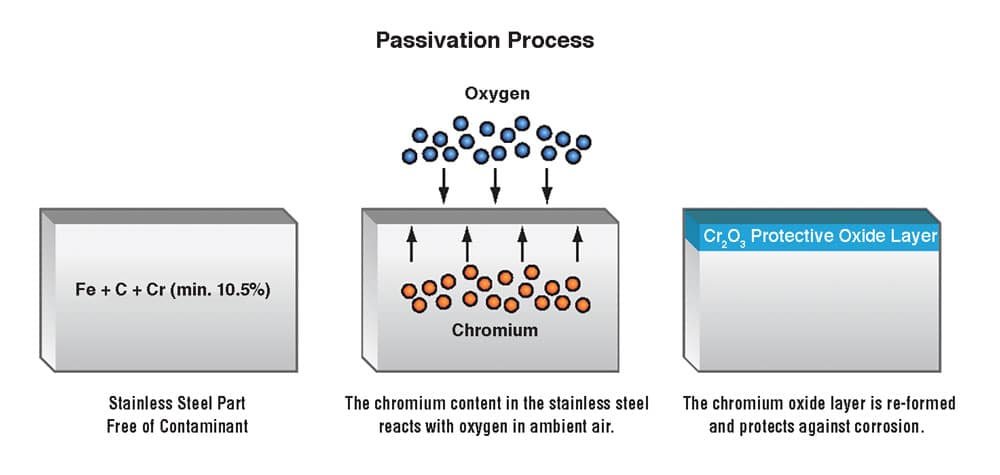

Passivation of stainless steel starts after pickling has been finished. The parts are treated with acid mix (or pastes) or electrochemical processes, to clean the contamination and expedite the formation of the chromium oxide passive film.

Thus passivation enhances the corrosion resistance of the stainless steel material after pickling to form a fresh oxide layer.

‘Passive’ means less affected by environmental conditions. Passivation of stainless steel gives back stainless steel to its original state.

As you can see in the above figure, it frees the surface from any free iron and expedites the natural Cr-oxide layer formation.

The passivation process uses nitric acid (HNO3) chemicals/ pastes that have to be applied on the material surface.

The chemical reaction by these acids cleans the stainless steel surface from any free iron contamination (if not removed can be an initiation point for the corrosion) left after pickling.

Process control is an important factor for successful surface treatment by passivation. Passivation does not remove any material during the treatment while there is material removal from the surface of the stainless steel in pickling.

Pickling and Passivation Chemicals/Acids for Stainless Steel

The main chemical for pickling & passivation of stainless steel (Austenitic Stainless Steel & Duplex Stainless Steel) are:

- H2SO4 (Sulfuric acids)

- HNO3 (Nitric acid)

- HF (Hydrofluoric acid)

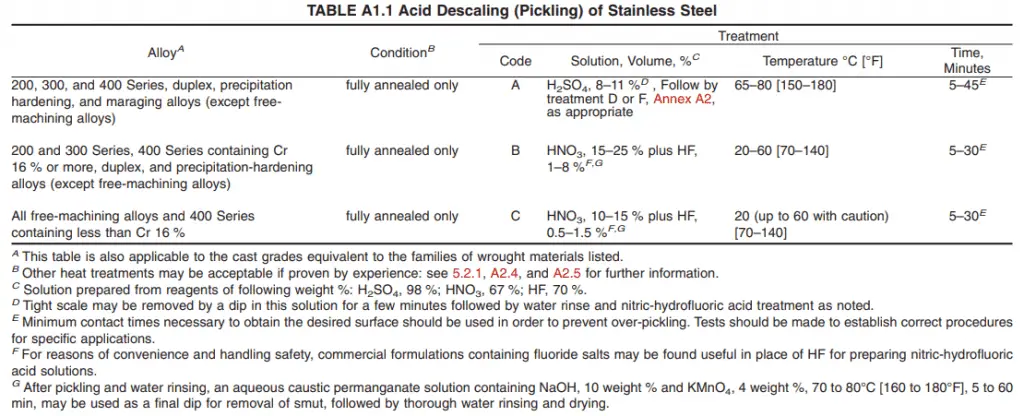

Pickling is carried out using H2SO4 (Sulfuric acids) or HNO3 (Nitric acid) solutions at a temperature of 20 to 80°C (70- 180°F). The time for the treatment varies from 5 minutes to 45 minutes.

The complete details about pickling chemical, temperature limit, and treatment time is given in the below table from the ASTM A380 standard.

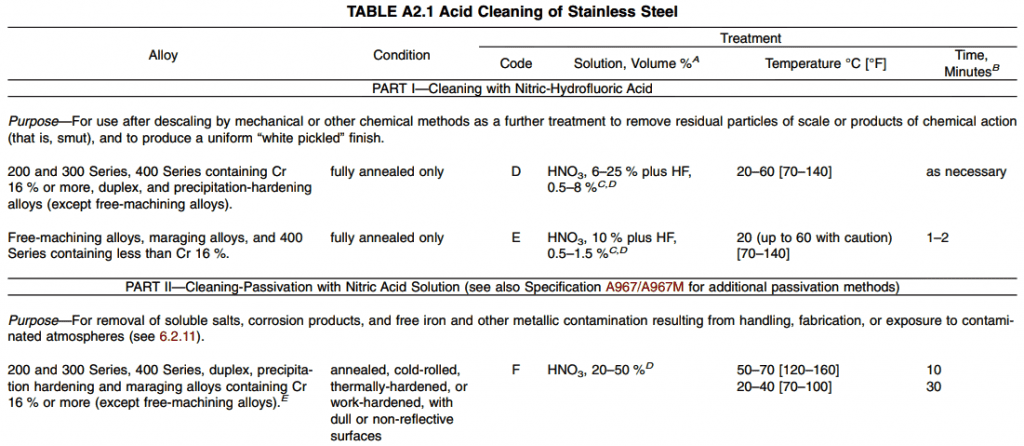

Similarly, for the passivation process- the chemical, temperature limit, and treatment time are given in the below table from ASTM A380 standard.

Passivation treatment is carried out using the HNO3 (Nitric acid) solution at the test conditions as follows:

Pickling and Passivation of Stainless Steel Procedure

The pickling and passivation of stainless steel procedure provides a step-by-step guide on how to properly clean and protect stainless steel.

Pickling and Passivation of Stainless Steel Procedure covers the use of nitric acid and hydrofluoric acid for pickling, as well as the use of a chromic acid bath for passivation.

It is important to follow all safety precautions when working with these chemicals, including wearing personal protective equipment (PPE).

Click here to download Picking & Passivation of Stainless Steel Procedure.pdf

What are the Benefits of the Pickling & Passivation Process?

Pickling and passivation are important processes in metalworking that serve to protect the surface of a metal part from corrosion.

The pickling process removes any impurities or contaminants from the surface of the metal, while the passivation process creates a protective layer on the surface that prevents further corrosion.

The benefits of these processes include increased durability and longevity for metal parts, as well as improved safety and reduced environmental impact. Picking & Passivation helps:

- Pickling & Passivation removes surface contamination.

- Enhance the corrosion resistance of the metals.

- Minimize the risk of metal contamination.

- Increased product life.

What are the Standards for Pickling & Passivation?

The most important Picking & passivation process code and standards are

- ASTM A380

- ASTM A967

- ISO 16048:2003

- BS EN 2516

- AMS 2700