What is Heat Tint in Welding?

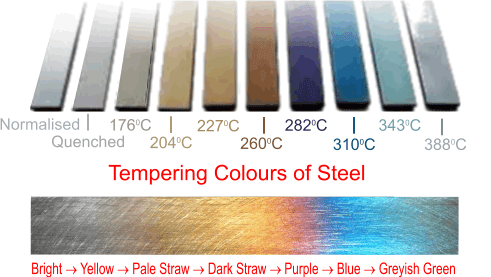

Heat Tint in welding (also called Temper Color) is a discoloration due to oxidation that can occur on the surface of welds. It is the result of the weld being exposed to high temperatures and oxygen during the welding process and is usually most noticeable on stainless steel.

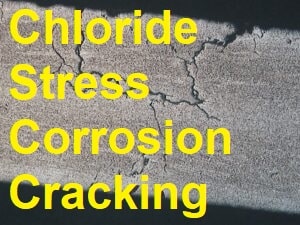

Heat Tint can range in color from light brown to black, and it can vary in intensity depending on the welding conditions. Heat tint can also affect the strength and corrosion resistance of the weld if the level of oxidation is high in stainless steel.

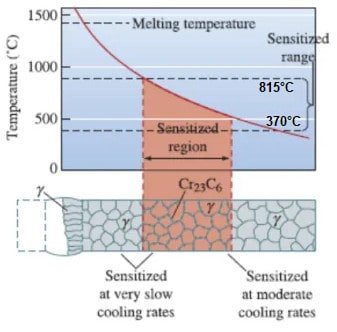

Heat Tints is visible on the areas that has attained high temperature during welding. What happen is that the chromium layer present on stainless steel surface get thickened and depending upon the temperature, it forms different colors by reacting with oxygen in atmosphere, commonly known as Heat Tint on Temper Color or Discoloration.

While Heat Tint is not necessarily harmful to the weld depending on the level of oxidation, it can affect the aesthetics of the finished product.

Weld Discoloration on Stainless Steel

Weld Discoloration on Stainless Steel can be unattractive, but it is not always indicative of a problem.

Some welders will purposely create a discolored weld for aesthetic reasons. However, if the discoloration is severe or there are other indications of problems, then it could be an indication of a welding issue.

There are several possible causes of weld discoloration on stainless steel, and a welder should be aware of them in order to avoid potential problems.

The weld discoloration on stainless steel is caused by:

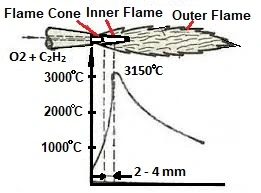

- Welding heat

- Using dissimilar filler wire than the base metal

- Lack of cleaning.

How to get rid of Heat Tint?

Heat tint is a common problem that can be caused by a number of factors, including using too much heat when welding or soldering.

You can get rid of Heat Tint by applying any of below method:

- Use inert gas shielding & purging during welding.

- Apply pickling and passivation after welding.

- Use polishing of the surface having heat tint.

- you can use a commercial product designed specifically for removing heat tint. These products are usually easy to use and effective at removing the tint.

How do you remove heat tint from stainless steel?

Heat tint, also called heat temper color, is a rainbow of colors that can develop on the surface of stainless steel when it is heated. The colors range from light yellow to dark brown and are caused by the formation of chromium oxide. Heat tint can be removed from stainless steel using either chemical or physical methods.

Chemical removal involves using a caustic solution, such as nitric acid called Pickling, to dissolve the chromium oxide. This method is effective but can be dangerous because of the corrosive nature of the chemicals involved, So use right PPE before you start pickling.

Physical removal generally entails sanding or grinding away the heat tint. This method is less likely to damage the stainless steel than chemical removal but may require more effort depending on how severe the heat tint is.