Welding Positions

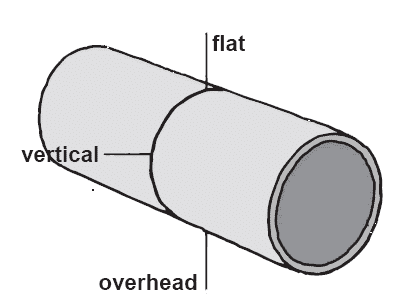

WELDING POSITIONS is the arrangement of the welding part or welding test coupon based on its axis slope and face rotation relative to its horizontal or vertical plane.

ASME Section IX defines the WELDING POSITIONS as Test position (e.g. 1G, 2G, etc.) and Production Weld Position (Flat, vertical, horizontal, etc.).

What are the Test Positions?

Test Positions means the welding position that is used for welding the test coupon/ ticket for welder’s qualification.

1G, 2G, 3G, 4G, 5G, 6G, 1F, 2F, 3F and so on- are the test positions. On the other hand, production weld positions refer to the weld position that is used for the welding on the actual job. Flat, Horizontal, Vertical and overhead, all of them are the weld position.

How many Welding Positions are there?

There are total 5 Pipe Groove Welding Positions as 1G, 2G, 5G, 6G, & 6GR and 4 Plate Groove Welding positions as 1G, 2G, 3G & 4G. Apart from this, there are total 5 Fillet Weld Symbols as 1F, 2F, 3F, 4F and 5F.

Understanding Welding Position

In ASME Welding Positions such as 1G, and 2G are for groove welds, and here ‘G‘- means Groove weld & in 1F, 2F, etc, ‘F’ means Fillet Weld.

Using the term Flat position for a welder test coupon is not the right approach. ‘1G’ for example, will be the right Welding Position that shall be used when qualifying a welder in a Flat position.

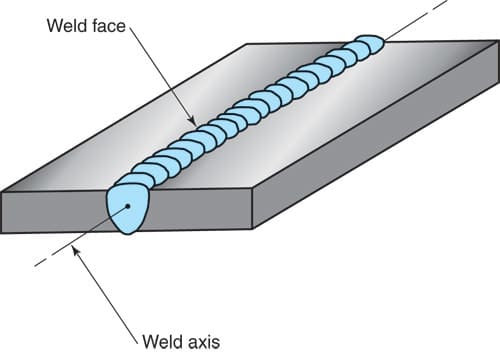

For understanding the Welding Positions, it is very important to first know the difference between the WELD FACE & WELD AXIS.

The below figure illustrates what is meant by a WELD FACE, WELD AXIS & PIPE/ PLATE Axis. These terms will help you to understand each Welding Position clearly.

- Weld Axis: is an imaginary line going past the weld center.

- Pipe or Plate Axis: Refer to the axis of the pipe or plate that defines its position in relation to the welding position. E.g. in the case of 1G Pipe Welding Position, the pipe axis is horizontal & weld axis is in a Flat Position.

What are the 4 Welding positions for Plate welds?

The plate is non-tubular material and usually does not involve rotation like pipe welding. Welding Positions when dealing with plates are given in ASME Section IX Figure QW-461.3.

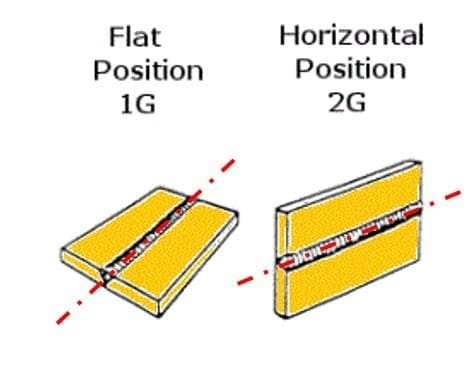

These Welding Positions are only limited to WQT for welder qualification. For plate, the Welding Positions (Shown in the below picture) specified in ASME Section IX, or AWS D1.1 are:

- 1G Welding Position, where ‘1’ means Flat Welding Position.

- 2G Welding Position, where ‘2’ means Horizontal Welding Position.

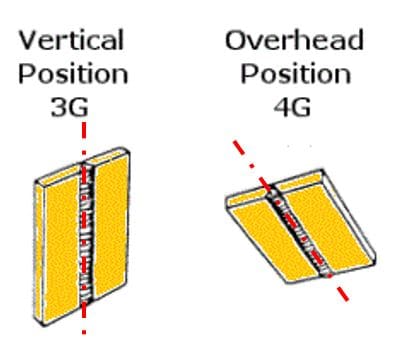

- 3G Welding Position, where ‘3’ means Vertical Welding Position.

- 4G Welding Position, where ‘4’ means Overhead Welding Position.

1G WELDING POSITION

1G Welding Position is for the flat position for welding. In a 1G Welding Position, the test piece is kept in a flat position and the welder performs the welding from the upper side of the welding joint.

Here, in 1G Welding Position, the axis of the weld is roughly horizontal & weld face remains in the horizontal plane. 1G or Flat position is called Downhand Welding Position.

In the Below sketch, 1G Welding Position, 2G Welding Position, 3G Welding Position, and 4G Welding Position are shown.

You can notice the weld axis running through the weld center in each of these welding positions. 1G Welding position is also applicable for the pipe.

2G WELDING POSITION

The example of a 2G Welding Position is shown above. In a 2G Welding position, the test piece is in a vertical position with a weld axis (red line) in the horizontal position.

The Weld’s face is parallel in the horizontal plane to the welder as he/ she deposits the welding. 2G Welding position is also applicable for pipe.

The welding is carried out in a horizontal welding position in a 2G position.

3G WELDING POSITION

3G Welding Position is also called Vertical Welding Position. As you can notice in the below figure that in a ‘3G Welding Position’ the Weld Face & Weld Axis, both are in a vertical direction or plane.

3G Welding position has two welding directions:

- Vertical uphill (3G Uphill)- When welding is performed from bottom to up direction.

- Vertical Downhill (3G Downhill)– When welding is performed from top to bottom direction.

4G WELDING POSITION

4G Welding Position is for overhead welding & also called Overhead Welding Position. The welder carries out the welding from the underside of the welding joint in a 4G Welding Position.

The 4G Welding Position is considered to be quite difficult in terms of welding position usability as weld metal tends to fall down due to gravity.

In the 4G Welding position, welding is carried out in an overhead welding posture. You must remember that there is no 4G position for pipe and the 4G Welding position is only applicable for Plate.

Test Positions for Groove Welding

Accordingly, the Groove welding Test positions are:

- Flat Welding Position

- Horizontal Welding Position

- Vertical Welding Position

- Overhead Welding Position

What is a Flat Position?

In the Flat Welding position, the test piece is kept in a flat position and the welder performs the welding from the upper side of the welding joint.

The axis of the weld is roughly horizontal & weld face remains in the horizontal plane. A flat position is called Downhand Welding Position.

In Flat Welding positions, 1G is for groove weld & 1F is for Fillet Weld.

What is Horizontal Welding Position?

In a Horizontal Welding position, the test piece is in a vertical position with a weld axis (red line) in the horizontal position.

The Weld’s face is parallel in the horizontal plane to the welder as he/ she deposits the welding. The flat Welding position is applicable for pipe & plate both.

In Horizontal Welding positions, 2G is for groove weld & 2F is for Fillet Weld.

What is a Vertical Welding Position?

In a ‘Vertical Welding Position‘ the Weld Face & Weld Axis, both are in a vertical direction or plane. Vertical Welding has two welding directions:

- Vertical uphill (3G Uphill)- When welding is performed from bottom to up direction.

- Vertical Downhill (3G Downhill)– When welding is performed from top to bottom direction.

In Vertical Welding positions, 3G is for groove weld & 3F is for Fillet Weld.

What is the Overhead Welding Position?

In Overhead Welding Position, the welder carries out the welding from the underside (bottom) of the welding joint.

4G overhead position is applicable for Groove welds while 4F is the overhead welding position for Fillet Welds.

Due to the gravity action, overhead welding is difficult compared to flat, horizontal & vertical positions. Welder usually deploys stringer beads to control weld puddles without any weaving in overhead welding.

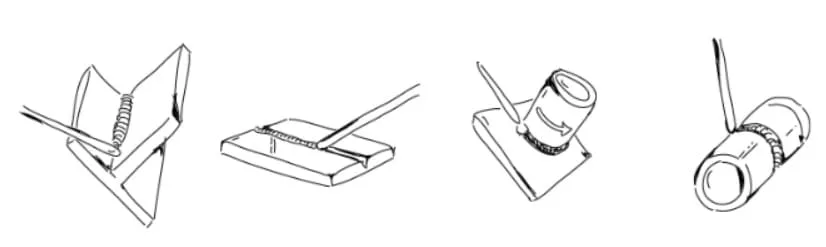

Welding Positions for Plate Fillet Welds

The above term is used for specifying the welding position for actual welding on the job. The welding Test position and production weld positions for the Fillet weld/ T joint are shown in the below picture.

The fillet weld in plate positions are:

- 1F or also called Flat Welding Position.

- 2F or also called Horizontal Welding Position.

- 3F or also called Vertical Welding Position.

- 4F or also called Overhead Welding Position.

What are the Welding positions for Pipe welds?

Pipe Welding positions are somehow similar to plate welding. For E.g. 1G & 2G positions are similar to plate welding position usability.

There are no 3G & 4G welding positions in Pipe Welding. Although, 5G, 6G, and 6GR are additional Welding Positions applicable for Pipe Welding.

Also, you will find that 5G, 6G, and 6GR are actually multiple Welding positions as welders perform welding in Flat, Vertical, horizontal, and overhead Welding in a single test coupon.

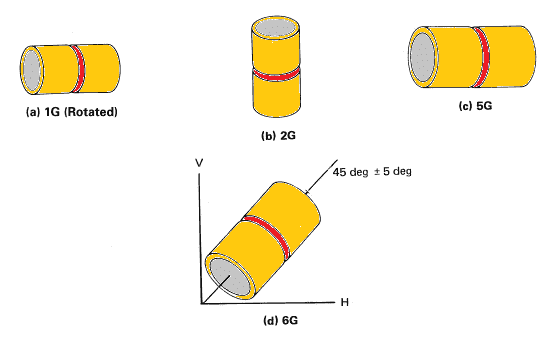

Pipe Welding Positions for Groove Welds

Welding positions for Pipe are different than the plate. Test positions for pipe welding that are used for welder ticket/ WQT qualification are given in the below picture.

Test positions 3G & 4G are not applicable for pipe and they are only used for plate welding. In addition, 5G and 6G positions are only applicable for pipe welding.

In summary, The main 5 Pipe Welding Positions are:

- 1G (Pipe rotates) Welding Position.

- 2G Welding Position.

- 5G Welding Position.

- 6G Welding Position.

- 6GR Welding Position.

What is a 1G Pipe Welding Position?

1G Pipe Welding Position (shown in the above figure) is a flat welding position for pipe Welding. It is also called horizontal rolled position in the non-standard definition.

1G welding position is used for pipe welding to carry out circumferential welding (usually groove welds). The pipe axis is horizontal and the pipe is rolled so that the welding position remains flat.

1G Welding Position is mainly used for robotic welding of pipes, cylinders, and welding of circumferential seams in vessels & tanks construction.

What is a 2G Pipe Welding Position?

The 2G Pipe Welding Position is used for circumferential seams welding for groove weld of pipe where pipe axis is in the vertical position and weld axis remains in the horizontal plane.

Welding is carried out in a horizontal position. Usually, the pipe is not rolled although there is no limitation. The pipe setup of the 2G welding position is shown in the above picture.

What is a 5G Pipe Welding Position?

5G Welding Position is applicable for Pipes only. In a 5G Welding Position, the pipe axis is kept horizontal plane (similar to a 1G Welding Position), and the pipe remains fixed (not rotated like 1G) till the welding joint is completed.

The welder performs the welding all around the pipe covering Flat, Horizontal, Vertical, and Overhead welding positions combinations. During Vertical welding, the welder can use either uphill progression or downhill progression.

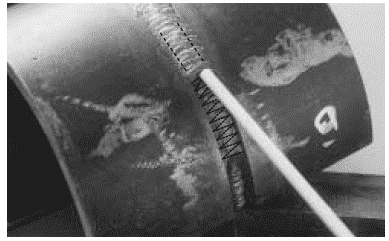

What is a 6G Pipe Welding Position?

6G Welding Position is applicable for pipe circumferential groove welding only. The pipe axis is inclined at 45° from the horizontal plane.

The pipe is not rotated until the welding is finished and the welder performs the welding from all around covering flat, horizontal, vertical, and overhead positions combined in a single pipe joint.

A 6G welding position for an actual weld joint is shown in the below picture.

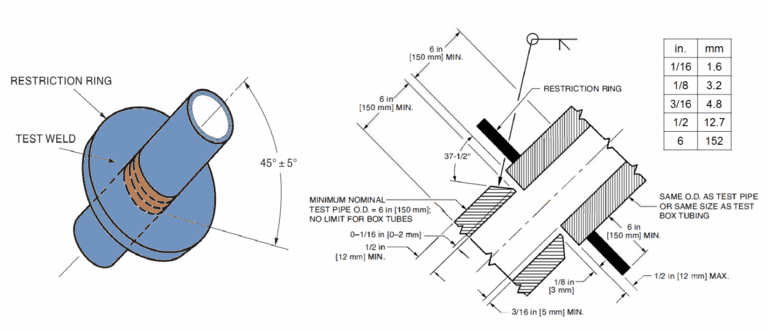

What is the 6GR Pipe Welding Position?

6GR Welding Position is similar to 6G welding in terms of weld axis and pipe axis. Although, in the 6GR position, only one pipe is having weld bevel preparation and an additional restriction ring is added to the test piece.

This ring regulates the welding access for the welder to test their skills to deposit a sound weld. A setup of the 6GR Welding Position is shown in the below figure.

6GR welding position is mainly applicable for offshore welding structures. Click the below link to learn about the 6GR welding position in depth.

What is the 6GR welding Test position? 6GR welding test tips and welder qualification

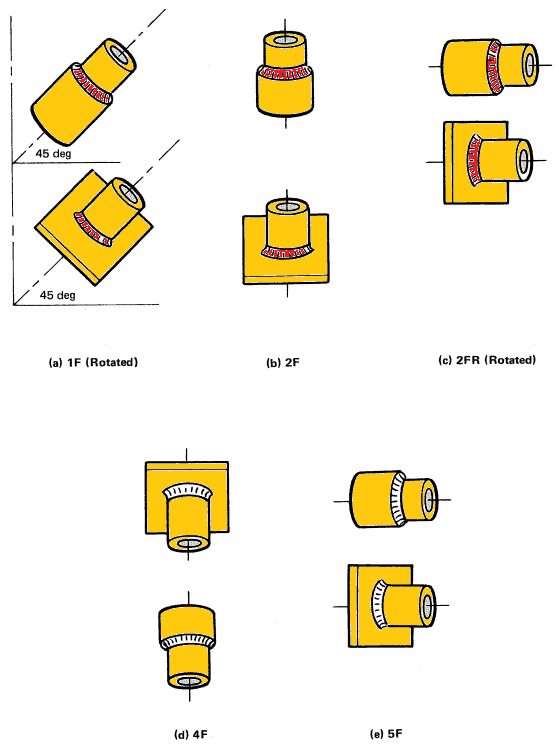

Pipe Welding Positions for Fillet Welds

There are fillet Welding Positions that are applicable for the pipe to pipe and pipe-to-plate welding. The main 5 Fillet Welding Positions for Pipe are:

- 1F (pipe rotates) Welding Position.

- 2F Welding Position.

- 2FR (Pipe rotates) Welding Position.

- 4F Welding Position.

- 5F Welding Position.

These pipe weld positions which are applicable in combination with pipe to pipe or pipe to the plate are shown in the below picture.

In the 1F, pipe welding position, the pipe is inclined at 45 degrees and rotates around its axis during welding.

In 2FR, the pipe is placed horizontal and arranged as a lap weld between two pipes, or a pipe welded transverse to the plate face is used. The test coupon rotates during the welding.

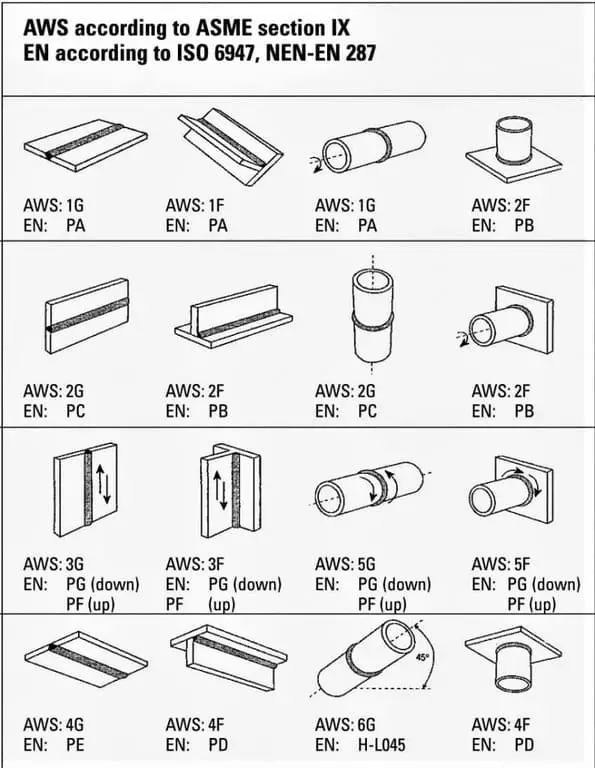

Welding Positions as per ISO 6947

ISO 6947: Welding and allied processes — Welding positions define the welding positions used in ISO, EN, DIN, BS, and NZ welding standards such as ISO 15614, ISO 15613, ISO 9606-1 & ISO 9606-2, EN15085 series, ISO 3834 series.

In ISO 6947, the welding position names are different than those used in ASME or AWS. A summary of ISO 6947 welding positions with respect to ASME Section IX is given below:

- PA: same like ‘1G’ for groove weld or ‘1F’ for fillet weld. The same Welding Position is used for Groove or fillet.

- PB: Only for fillet weld, ASME equivalent ‘2F’ Welding Position.

- PC: For groove weld only, equal to ‘2G’ Welding Position.

- PD: Only for fillet weld in the overhead position, ASME equivalent 4F Welding Position.

- PE: Only for groove weld in the overhead Welding Position, ASME equivalent 4G Welding Position.

- PF: For groove or fillet in vertical uphill progression Welding Position. ASME equivalent is 3G or 3F Welding Position.

- PG: For groove or fillet in vertical downhill progression Welding Position. ASME equivalent is 3G or 3F Welding Position.

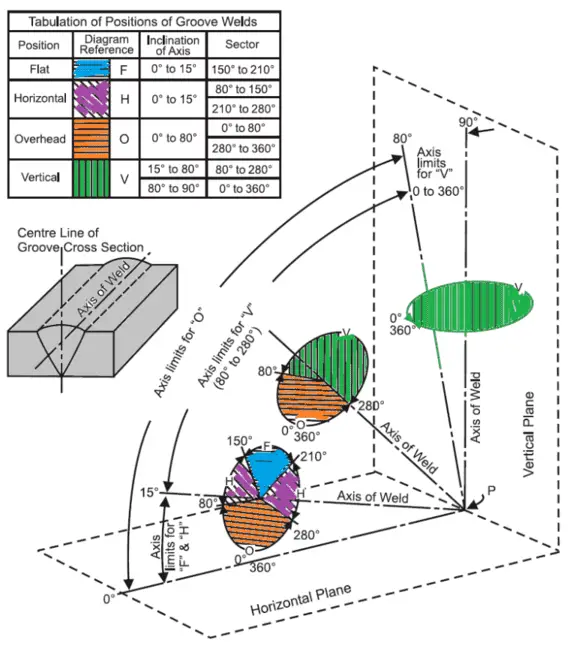

What is the allowed range for rotation and slope for welding positions as per ASME Section IX?

Here, For example- A flat position is having an inclination of axis from 0° to 15° & axis of the weld can have a slope of 150° to 210°.

Changing the angle to let us say 20° (vertical has an inclination axis of 15°- 80°), the new welding position will be Vertical even if the slope is within 150°-210°.

The below sketch shows the limitation of inclination angle and slope for welding positions.

Read more:

- Welding Positions Chart | Jasic Welding Inverters

- Welding Positions forum (aws.org)

- ISO 6947:2019(en), Welding and allied processes — Welding positions