What is a Groove Weld?

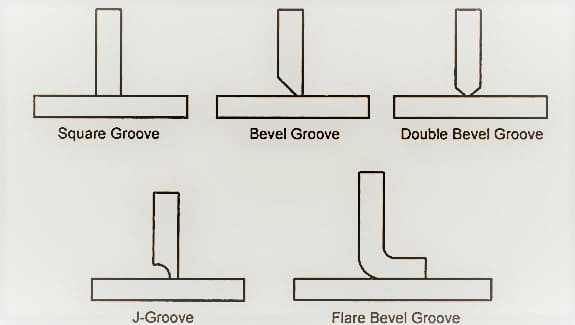

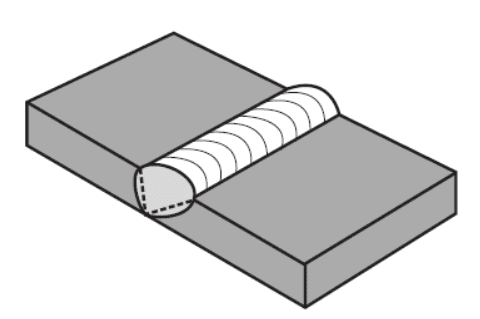

Groove weld is one of the types of weld joint (other types such as Fillet weld, Lap weld, Corner weld, etc.) where the weld is deposited in the groove obtained by two butting plates or pipe members.

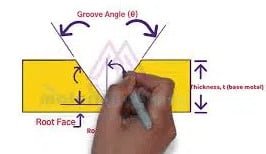

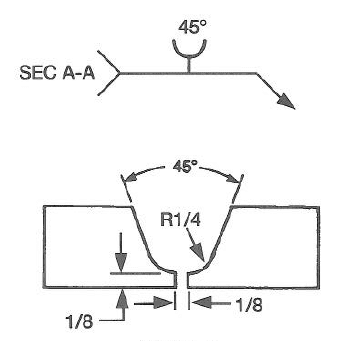

Groove weld or butt weld can be the same when butting members have grooves made on them. A simple single V groove weld is shown in the below picture.

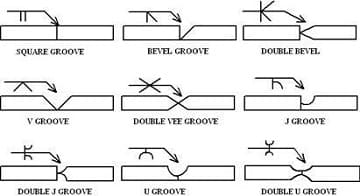

Types of Groove Weld

Groove weld has different types. The main two types are:

- Single V groove

- Double V groove

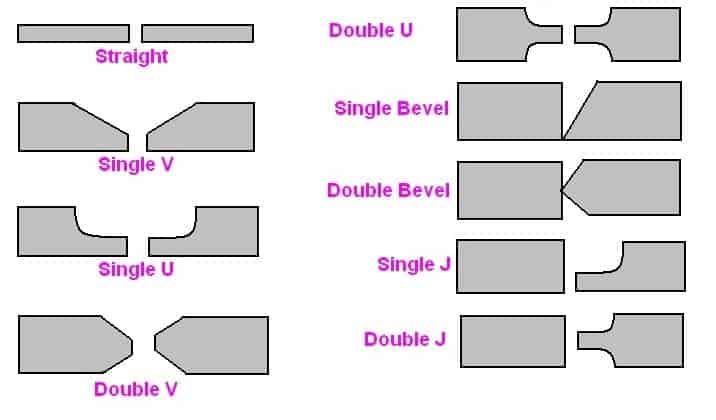

Further classification is based on the Type of Weld Groove Preparation– as shown in the below sketch for Single V, Single U, Double V, Double U, Single Bevel, Double Bevel, Single J, and Double J Groove weld.

So, the complete groove weld types are:

- Single Bevel/ Double Bevel Groove weld

- Single V/ Double V Groove weld

- Single U/ Double U Groove weld

- Single J/ Double J Groove weld

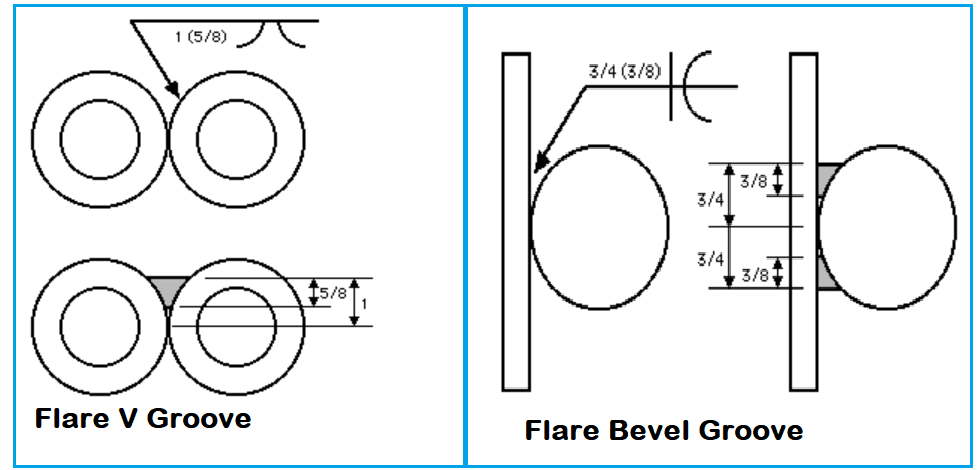

- Flare bevel Groove weld

- Flare V Groove weld

The shape of the groove preparation is the deciding factor for the type of groove weld.

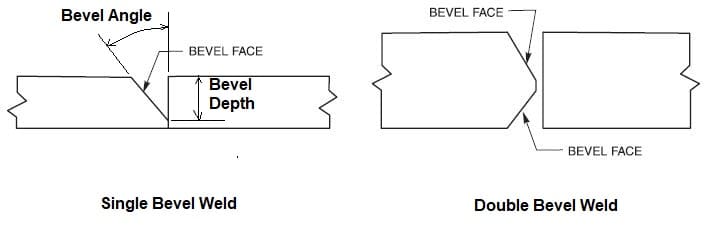

What is a Weld Bevel or Bevel Weld?

Bevel Weld means an angular edge prepared on the plate/ pipe for welding. The non-standard term used for Bevel is Scarf. The main parts of a Weld Bevel are:

- Bevel: Angular bevel shape edge.

- Bevel Angle: Angle between bevel & a plane perpendicular to the plate/ pipe surface.

- Bevel Face: Angular prepared surface of the bevel.

- Bevel Radius: Applicable for ‘J’ groove, refer to the radius of the ‘J’ Groove.

- Depth of Bevel: Perpendicular dimension from root edge or root face beginning to the top of the base material surface.

What should be the bevel for welding?

The size of the weld Bevel depends on the base metal thickness & weldability access to ensure sound weld fusion.

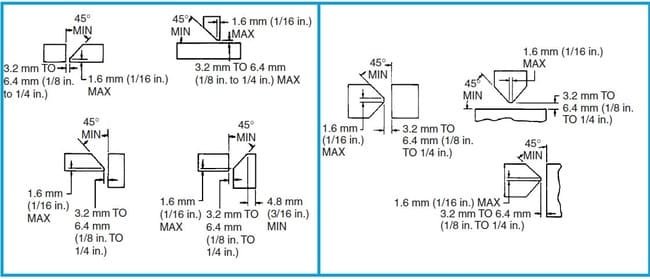

The recommended bevel angle, root face, root gap, and other important tolerances are given below for reference (Ref. AWS Handbook, Volume 1).

The bevel angle in the case of a single Bevel weld is kept usually at a minimum of 45° & maximum of 60°.

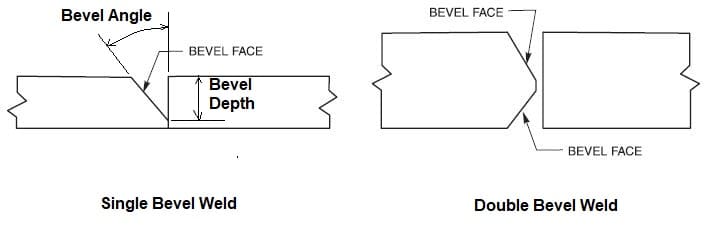

Single Bevel Groove Weld

Single Bevel Groove Weld is similar to a V Groove weld in terms of welding applications & properties. Single Bevel Groove Weld needs less joint preparation & less weld metal (usually equal to a fillet weld) compared to a ‘V-Groove’ Weld & hence more economical.

The main issue is the lack of fusion risk associated with the perpendicular face of the weld joint. Such joints are challenging to achieve full penetration in the root.

An example of a Single Bevel weld is given below. These types of joints are good for thickness up to 3/4 inches or 19 millimeters.

During welding, the face without a bevel shall be kept on the lower side to achieve a good weld fusion on the unbevel face. For higher thickness, it is advised to make a double-J groove weld.

The angle of the bevel in a Single Bevel Weld is usually 45°-60°.

Double Bevel Groove Weld

Double Bevel replicates a Double V-Joint on one side & the other side is having only a perpendicular face as shown in the above figure for the Double Bevel Weld Joint configuration.

Due to the perpendicular face of one side member, the bevel weld demands the electrode to be angled indirectly into the bevel groove near the vertical perpendicular face.

Due to this reason, bevel welds are limited to be welded only in a flat position for some welding processes.

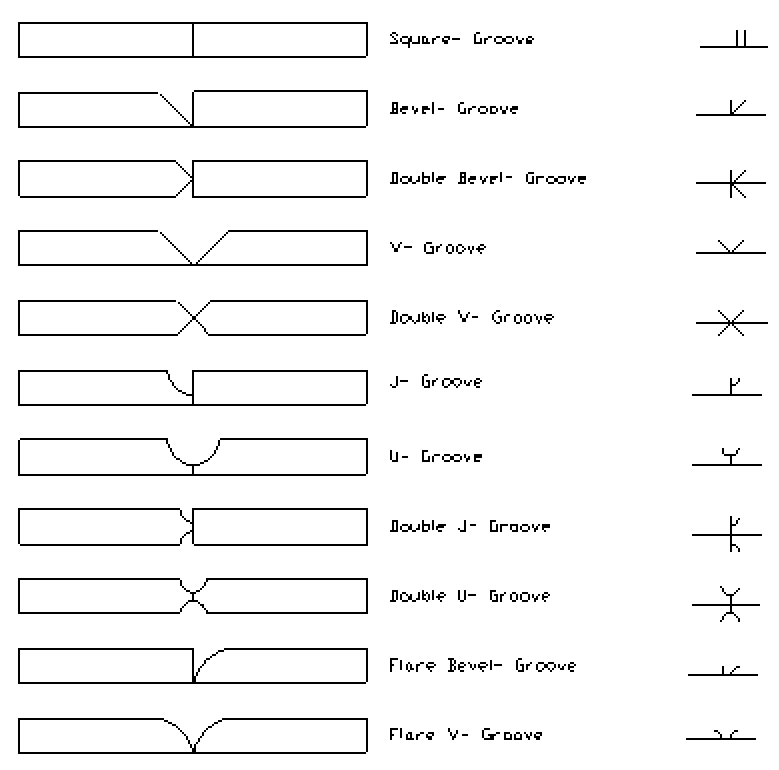

Welding Symbol for Single & Double Bevel Weld

Welding Symbols for Single Bevel, Double Bevel, Square groove, V Groove, Double V Groove, Single J Groove, Double J-Groove & Single- Double U Groove is shown in the below welding symbol example.

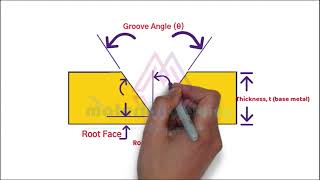

Parts of a Groove Weld

The parts of a Groove Weld (Butt Weld) are- Root face, Bevel face, root gap, bevel angle, Groove angle, or included angle.

Watch this video to learn in detail about parts of a groove weld and the types of weld beads and layers in a groove weld.

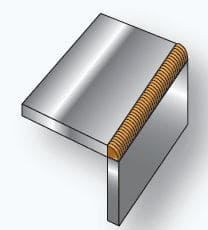

Groove weld vs Fillet weld

A groove weld is between the two members in the same plane butting to each other while in a fillet weld or T joint, the two members are joined to each other at a 90-degree angle in general, the exception is Skewed Fillet Joint. Click here to learn the types of joints- Fillet & Groove Weld.

Bevel Weld vs Fillet Weld

Bevel Weld & Fillet Weld are similar in terms of weld configuration and usually have equal weld metal volume. But Bevel Weld can be a complete joint penetration (CJP) weld but not in the case of a Fillet Weld (Exception- fillet weld with groove).

Hence, the Bevel weld is much stronger than the Fillet weld that is prone to loading failure due to a lack of through-thickness weld penetration.

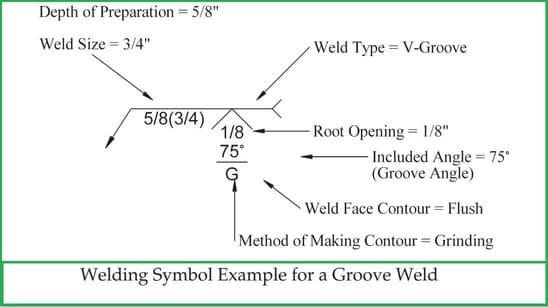

Groove Weld Symbol

A groove weld symbol consists of a reference line, arrow line, weld symbol, and additional supplementary weld symbol with tail if required.

In the below example of a groove weld symbol, the weld symbol for the ‘V’ groove of 1/8” root opening, 75 Deg included angle and face contour flush by grinding. The depth of weld penetration is 5/8 inches and weld size is 3/4 inch.

Groove weld symbols are based on the type of groove preparation. The symbol for V groove, J Groove, U Groove, flare groove, single Bevel, Double V, Double U, Double J, etc. are shown in the below picture.

Watch this video to learn Welding Symbols from scratch.

What is J Groove Weld?

J Groove Weld is a special type of Groove Weld that is more economical by lowering the weld metal volume. J Groove can be a single Bevel J-Groove or Double Bevel J-Groove as shown in the above weld joint configuration.

A Single J-Groove is Welded from one side while a Double J-Groove is welded from both sides. Compared to V-Groove, J Groove is more difficult to weld due to one side perpendicular face.

J-Groove are more economical & suited best for welding in a Horizontal welding position for higher thickness materials. The flat face side is kept on the lower side during welding.

The amount of saving in terms of welding filler justifies the cost of machining to prepare the J-Groove when welding thicker sections. For thin material, it is better to go for a Bevel weld that is easy & more economical.

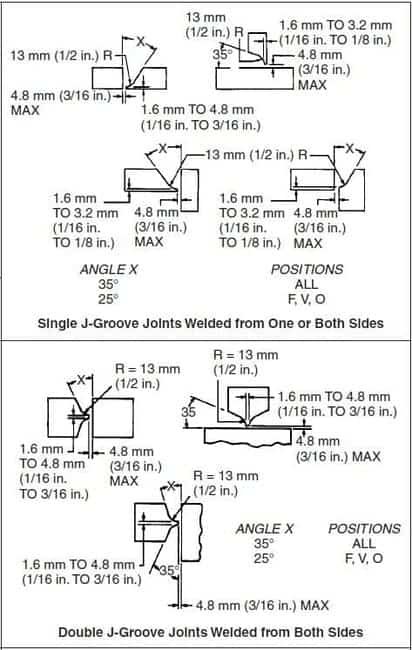

J-Groove Weld Preparation & Dimensions

The weld preparation of a J-Groove is carried out by machining or specially designed weld beveling arrangement due to its critical groove radius. The important parts of a J-Groove are given below:

- Bevel Angle (X)

- Groove Radius (R)

- Root face (R) &

- Root gap

The recommended J-Groove dimensions such as bevel angle, groove radius, root face & root gap are specified in the below figure:

U-Groove Weld

U-Groove welds are similar to J-Groove. While J-Groove represents a similar weld configuration like a Bevel Weld, U-Groove are similar to a V-Groove weld.

U-Groove preparation is also carried out by machining or specially designed weld beveling machines like a J-Groove.

U Groove Weld is having two types:

- Single U-Groove Weld

- Double U-Groove Weld

As there is a groove on both joining members, U-Groove is easy to weld in all positions & also easy to achieve complete fusions.

Contrary, the U-Groove Weld configuration increases the volume of weld metal compared to the J-Groove weld. But it is still less than a V-Groove. U-Groove is very useful for thicker sections to reduce the cost and weld metal volume.

The Welding Symbol for a Single U-Groove and weld joint configuration for Single U-Groove is shown in the below figure.

Types of loading (Stresses) in a Groove Weld

A Groove weld is used in a fabricated component usually to provide the same strength as the base metal. Most of the groove welds is full penetration weld joints subjected to bending moments and tensile stresses.

When groove welds are subjected to tensile loading, the stresses flow parallel to the base metal. Groove welds used in bridges, structures, etc. are subjected mainly to bending moments.

Similar Posts