Flare Bevel Weld

A flare bevel Weld is a type of weld where a groove is formed between a radius edge on a plane surface. In a flare bevel weld, one member have a curved surface and another is flat surface.

This post covers what is flare bevel, flare bevel weld types, flare bevel welding symbols and example of actual Flare Bevel welding application used in different industries.

What is Flare Bevel Groove weld?

A flare bevel Groove Weld is a type of weld where a groove is formed between a joint member with a curved surface and another with a planar surface.

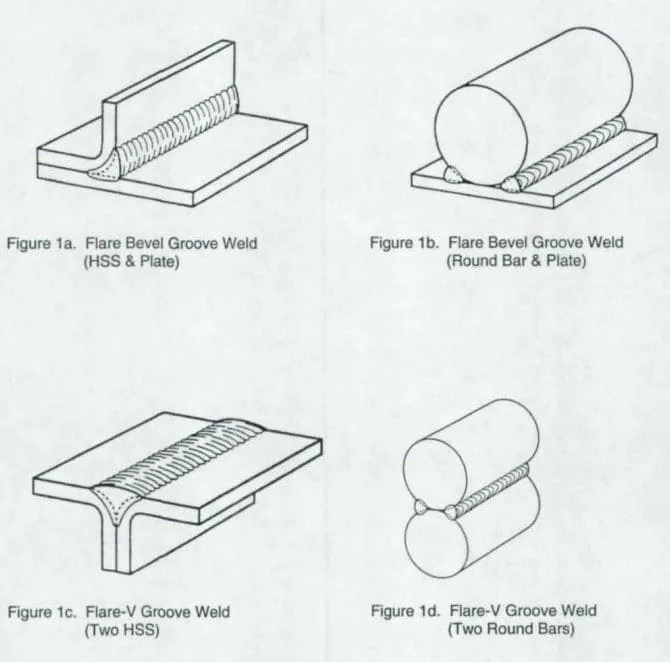

So, for a flare bevel groove to take place, atleast one joining member needs to be a tubular shape or curved edge. For example, a weld formed between a pipe and plate placed horizontally to each other or other possible combinations as shown in the below figure.

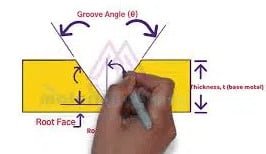

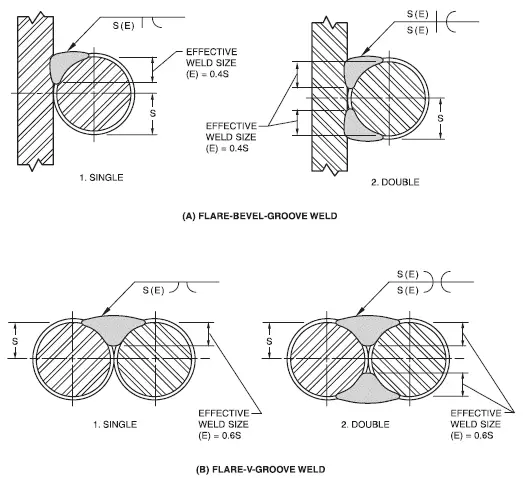

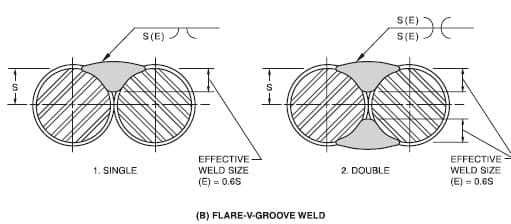

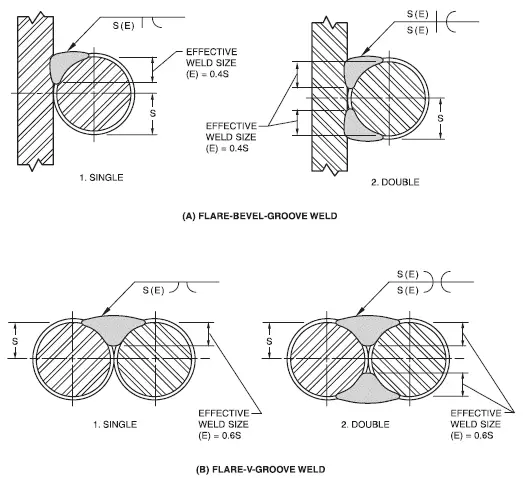

Flare groove welds arise when a convex surface makes up the joint preparation in a Partial Joint Penetration (PJP) groove weld (see Figure 1). These welds occur when one or both components of a joint consist of a round bar or 90· bend in a formed section, for example a Hollow Structural Section (HSS).

The fabrication of HSS structures involves joints where flare bevel (Figure 1a), and to a lesser extent, flare-V (Figure 1 c) groove welds are common. The deposition of sound weld metal to the bottom of the flare is very difficult because the welding puddle bridges between the two surfaces and then penetration into the root is inhibited.

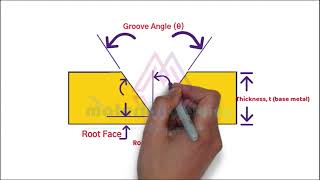

Hence, the extent of root penetration in flare bevel groove welds is dependent on the angle between the fusion faces, and therefore the outside corner radius or profile of an HSS is a major parameter determining the geometry of the weld.

Welding Symbol Chart (desk Size)

Welding Symbol Chart (Wall Size)

Alternative Names of the Flare Bevel Weld

Flare Bevel Weld is also known by many other names. Other common names include:

- Single Flare-Bevel-Groove Weld

- Double Flare-Bevel-Groove Weld

- Single Flare-V-Groove Weld

- Double Flare-V-Groove Weld

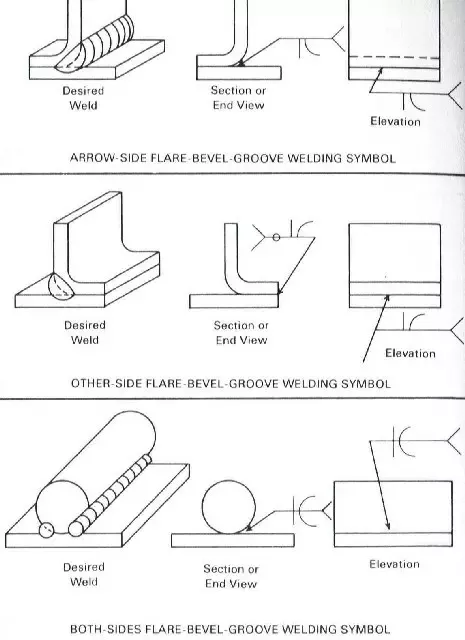

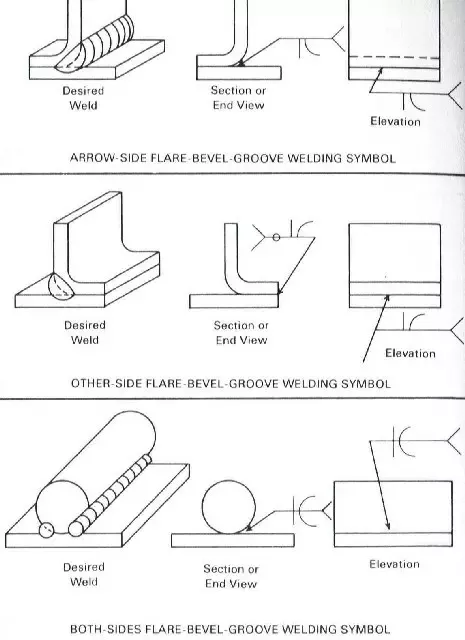

Flare Bevel Weld Symbol

The Welding Symbol for Single Flare Bevel-Groove Weld, Single Flare V-Groove Weld, Double Flare Bevel Groove Weld & Double Flare V Groove Weld is shown in the below example.

- Single Flare Bevel Weld Symbol: A single flare bevel weld symbol is formed by vertical line on left hand side & a curved flare line on right side of the welding symbol. Example 1 (top left side) in the below picture shows the welding symbol for single fare bevel weld.

- Double Flare Bevel Weld Symbol: The welding symbol for double flare bevel weld is symmetrical weld symbol of single flare as shown in the Example 2 on top right side in below figure.

- Single Flare V Groove Weld Symbol: Weld symbol for Single Flare V groove consists of two curves placed on reference line as shown in above figure 1 left hand bottom side.

- Double Flare V Groove Weld Symbol: A Double flare V groove weld symbol is shown in above figure 2 bottom right side.

You will notice that the weld Symbol of a Flare weld reflects the weld joint shape.

Flare Bevel Weld Examples

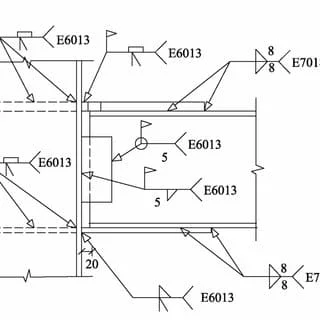

Flare Bevel and flare Groove welds are predominantly used in structural, bridge, and shipyards. In structural fabrications, welds known as -T, -K, -Y welds are formed mostly as flare bevel welds. These welds due to their critical applications require extensive inspection.

A tubular member can be made from a plate having a curved surface or it can be a round member.

Types of Flare Bevel Weld Groove

The four main types of a Flare Bevel Weld Groove are:

- Single Flare-Bevel-Groove Weld

- Double Flare-Bevel-Groove Weld

- Single Flare-V-Groove Weld

- Double Flare-V-Groove Weld

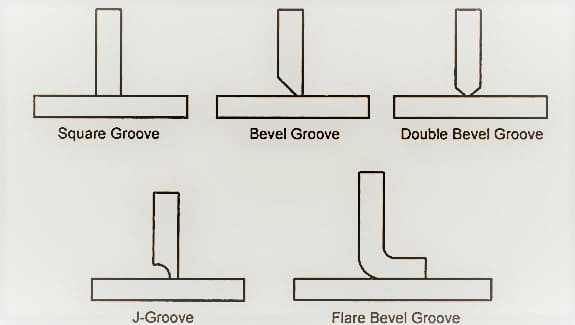

What is Single Flare-Bevel-Groove Weld?

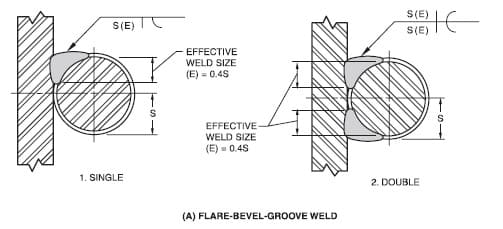

In a Single Flare Bevel Groove Weld joint configuration, a round member (Pipe/ round bar) having a curved surface is rested on a flat surface. The Flare weld is obtained by welding lengthwise to one side of the weld joint.

Refer below figure, top left for an example of Single Flare Bevel Groove Weld. The Welding Symbol for Single Flare Bevel Groove is also shown in this example.

Double Flare-Bevel-Groove Weld

A Double Flare Bevel Groove Weld is similar to a Single Flare Bevel Groove Weld except that it is welded from both sides.

Refer above figure, top right for an example of Double Flare Bevel Groove Weld. The Welding Symbol for Double Flare Bevel Groove is also shown in this example.

Single Flare-V-Groove Weld

A Single Flare V-Groove forms between two round (pipe/bar) parts that are placed side by side to each other. The welding is carried out lengthwise of these round parts. Here round parts are usually a pipe or round bars or can be rolled from the plate.

Refer Below figure, bottom left for an example of Single Flare V-Groove Weld. The Welding Symbol for Single Flare V-Groove is also shown in this example.

Double Flare-V-Groove Weld

A Double Flare V Groove Weld is similar to a Single Flare V-Groove Weld except that it is welded from both sides. Both are members are butting together and welded in the lengthwise direction.

Refer above figure, bottom left for an example of Single Flare V-Groove Weld. The Welding Symbol for Single Flare V-Groove is also shown in this example.

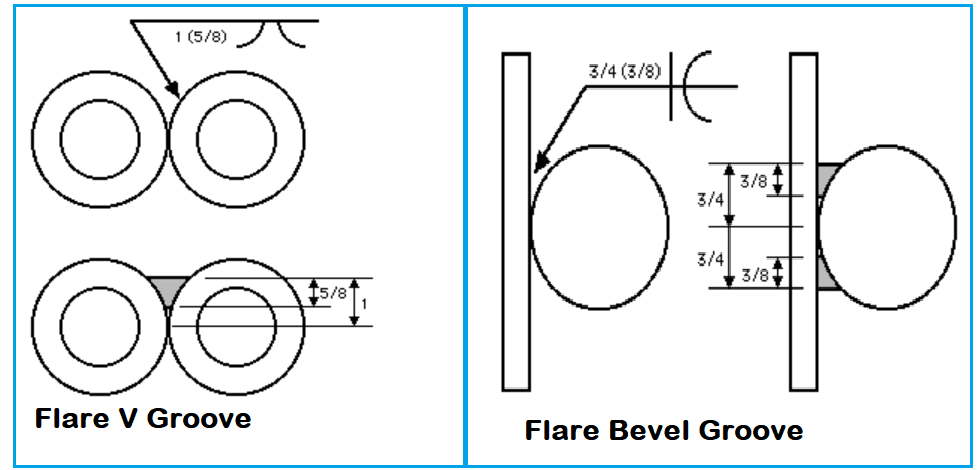

Flare Bevel & Flare V-Groove

The figure above shows a Flare V Groove weld and flare bevel groove. A flare V groove is formed between both the members having curved surface or let’s say when the members are tubular shape.

A flare bevel weld is formed one of the members is having a curved surface while another member is a flat either plate or rectangular bar, for example.

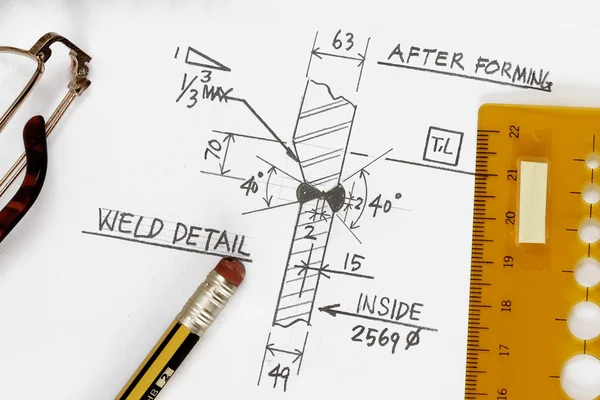

Flare Bevel Weld Size with Design Example

The effective Weld Size of a Flare Bevel Weld Size is equal to 0.4S minimum, where, ‘S’ is the radius of the round member. In the case of a Flare Bevel V-Groove, the effective Flare Weld Size is equal to 0.6S.

Effective size of Flare Weld = 0.45 x S

Where, S= Radius of the round member.

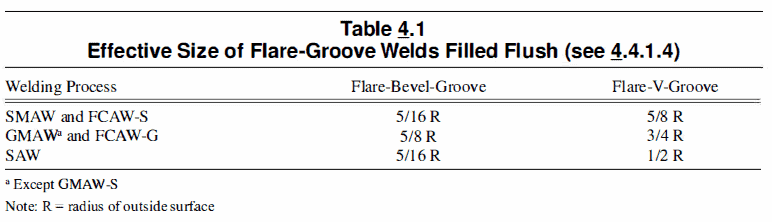

Here, you must remember that weld reinforcement is not regarded for flare bevel groove weld size. You can also refer to AWS D1.1, Table 4.1 for the effective size of a Flare Groove Weld as explained later in this post.

Refer to the below figure again to understand the design example of a Flare Bevel Weld, it’s welding symbol, and effective flare bevel weld size.

How to Measure a Flare Bevel or Flare Groove Weld?

Measurement of a Flare Bevel or Flare Groove Weld requires expertise and inspection skills. Usually, measurements are done using the leg length of the flare groove.

based on the joint geometry, a minimum leg length shall be specified. A weld filled at least minimum to the specified leg length or higher will guarantee that the weld is having the required size. Similar, practices can be adopted for Flare V Groove welds.

AWS D1.1 provides insightful information on measurements of Flare welds. Clause 4.4.1.4 provides information on the effective size of Flare Groove Welds.

Table 4.1 states the effective size of flare groove welds when filled flush.

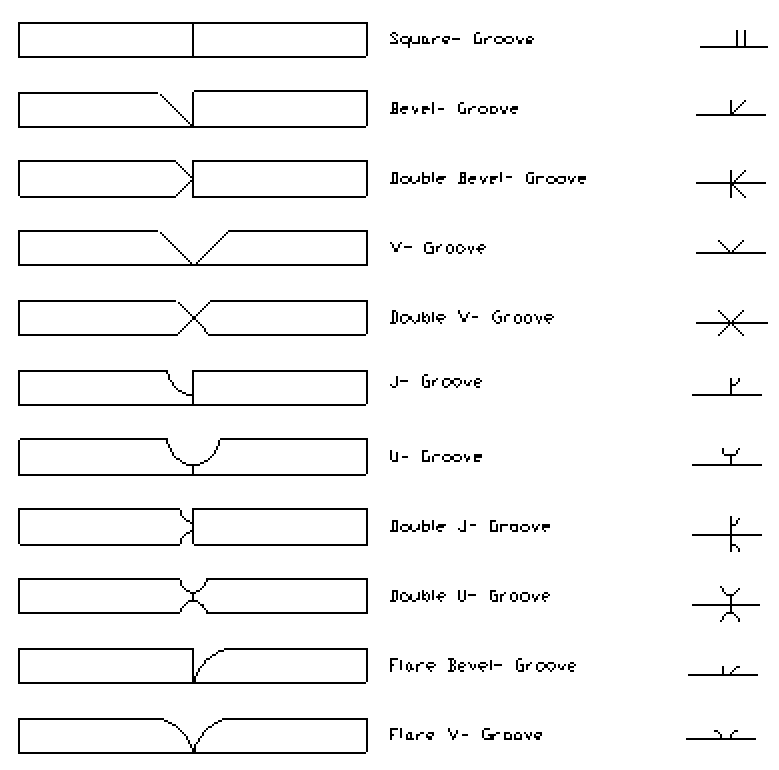

Does a Bevel Weld a Groove Weld?

A Bevel weld, whether it is a single bevel (2nd sketch in below pic) or double bevel (4th sketch) is a groove weld because a groove weld refers to the weld preparation involving the weld bevel.

Bevel means the prepared angle on an individual plate or pipe material. In the case of Single-V (4th sketch in the below picture), both plates are having a bevel angle.

A Groove weld can also occur if one plate is having a bevel angle and the other is having no weld preparation (refer to 2nd sketch in the below picture).