What is a Weld map or Weld Trace or Weld Logs?

A Weld Map tells what to weld, where to weld, and how to weld. A weld map is a type of drawing for numbering the weld joints to work as a guide for the welder & production.

Each weld on the drawing is given a specific number (you can choose any number you want, but usually we write a W1, W2, and so on or identifies as CS1, CS2, etc., in case of circumferential seams).

These numbers are then further elaborated to highlight the joint location, applicable WPS for each weld, thickness for the specific weld, and other essential variables for that specified joint, used to number each of the welds or joints on it.

Welding Map Example with sample

Weld Map Examples are important when trying to create a weldment. Often there are many parts to a weldment, and it is important to know where each weld goes & what’s the information for these welds welder needs to know.

“Weld maps help organize the welding process and make sure everything is in the right place.”

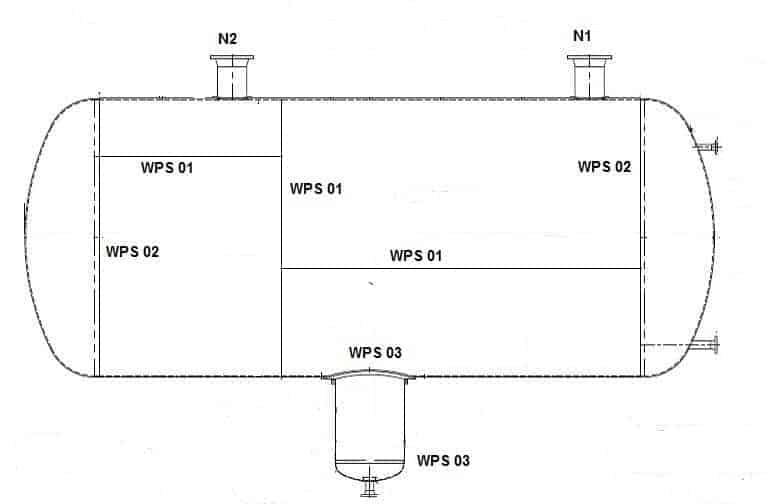

See the weld map example below; this Welding Map example includes nine welds of pressure vessels. This weld map shows welds with circumferential seam, longitudinal seam, and boot weld. Nozzle weld and support pad weld are not covered in this weld map.

The below sketch shows a weld map for a vessel. Here, four WPS’s are given for the welding of this part.

Another example of this weld can be made by numbering the weld seam and then referencing these weld seams along with their respective WPS in a table.

- WPS No. 01 is for long seams and circ-seam of the vessel.

- WPS No. 02 is for dish head to shell weld.

- WPS 03 is for the nozzle to shell.

A welded component can have a number of WPS which need to be shown on the drawing. A weld map is the best to help with it.

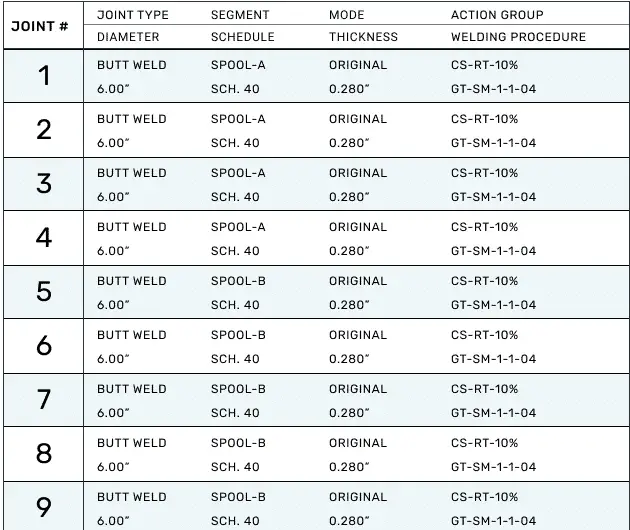

The weld map can also be made in a table showing the joint number, applicable WPS, material thickness, type of joint, welding process, and any other essential details as deemed necessary.

he weld map is a non-standard requirement and can be given in any way that suits best to the manufacturer and satisfies the client’s requirements.

How to Make Welding Map?

The first step in creating a weld map is to identify the type of joint you will be welding & give numbering to them.

There are six basic types of joints: butt, corner, tee, lap, edge, and fillet.

Once you have identified the joint type, you need to determine the size and shape of the weld area. Draw a diagram of the part you are welding and label the weld numbers.

Next, list each weld type, material, joint size, and applicable WPS against each weld number.

These weld numbers are referenced to the welding drawing and the welding log sheet provide full details of each these welds such as joint type, WPS, material, thickness & any other relevant information as deemed necessary for an effective weld mapping.

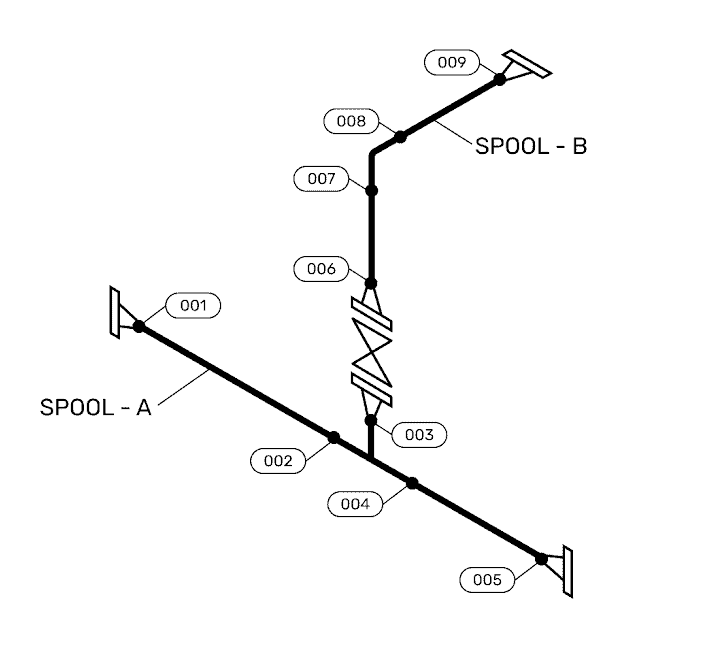

Weld map for Piping

A weld map and weld log support each other. The joints given on a weld map are transferred on the weld log with the help of both, detailed information on welding is provided to the user. A weld map tells what to weld, where to weld, and how to weld.

The weld map provides a visual of the weld joint to easily locate them during the fabrication stage. The below sketch shows a weld map of a piping spool. Here, weld joints are identified from 001 to 009 i.e. there is a total of 9 welds.

A weld log is created as shown in the below sample, which shows the applicable joint number, type of weld, segment identification, material thickness, and applicable WPS.

Such logs are very beneficial to aid a brief WPS package review to the Welding engineers, welding inspector, and shop persons.

Why weld maps and weld logs are required?

A Weld map works as a guide to the welding shop to provide necessary information for the fabrication of a component. Each welding code, client, and the company will have a standard practice to address the requirements applicable to the scope of the project.

Such logs are very beneficial to aid a brief WPS package review to the Welding engineers, welding inspector, and shop persons. A weld map tells what to weld, where to weld, and how to weld. The weld map provides a visual of the weld joint to easily locate them during the fabrication stage.

What is a weld log sheet?

A weld log sheet is a form that documents the welding process. The form includes information such as the type of weld, the size of the weld, the material being welded, and the welding parameters.

Welders use this information to ensure that the welds are consistent and meet quality standards.

Weld Map & Weld Logs Template

A Sample Weld Map Template can be downloaded from this link. You can use this or a similar format for your weld map requirements.

Sample List Detail Welding Map | PDF | Joining | Transition Metals (scribd.com)

A weld map sheet is a valuable tool for welders. It is a simple, two-dimensional drawing or a sheet that shows where all the welds will be on a particular part or structure.

Welders can use this sheet to plan their work and make sure they have all the necessary information on hand. The map should show the weld size, applicable WPS, and location of each weld.

A weld map sheet can be created in a variety of ways, depending on the welder’s preferences and capabilities.

Some welders prefer to use CAD software to create a digital weld map, while others prefer to draw by hand. No matter which method is used, the key is to ensure that the map is clear and easy to read. Welders often use a different color for each type of weld.

WELD MAPPING SOFTWARE

Weld mapping software is a computer program that helps to create digital weld maps accurately. The software creates a map of the weld area, which helps the welder to see the required welding details.

This can help to prevent mistakes and ensure that the weld meets the welding quality requirements. Weld mapping software is available for both Windows and Mac computers.

Weld Map Symbols

When it comes to weld maps, there are no standard symbols that need to be used. This allows for each shop to create their own symbols to represent the weld number in a drawing.

Read more: Learn easily How to Use WELDING SYMBOLS?

This is beneficial because it helps to ensure that everyone is on the same page and knows which welds need to be completed.

It is important to note, however, that each weld should be denoted on the drawing. These number shall be matched on the weld log to provide full information about these welds. This will help avoid any confusion or mistakes down the line.

These weld mapping symbols are can be useful for a better pictorial weld map representation for its users. In practice, people usually use a circle attached to a arrow line pointing to the weld. Welding number is placed within the circle that corresponds to the weld log.