E6013 or E7018 Rod?

Many welders and engineers get this query in their day-to-day work life. For most of them, E6013 is a good choice as it offers:

- Clean-looking welds.

- Ease in welding, good arc start.

- Easy slag removal

- Good for welding sheet metals

But, all in all, E7018 dominates in terms of good welding strength (70 Ksi compared to 60 Ksi or E6013) and sounder weld compared to E6013 type electrode.

Read more:

- Everything you should know about E6010 Rod.

- Everything you should know about E6013 Rod.

- Everything you should know about E7018 Rod.

E7018 produces welds of x-rays quality with very good weld toughness, so obviously, E7018 is an electrode of high quality. But being low hydrogen, E7018 does require Electrode Baking at a temperature of 500 to 800°F (260 to 425°C) and storage in the temperature range of 250 to 300°F (120 to 150°C).

Polarity difference between E7018 and E6013

Both E6013 & E7018 are electrodes for Carbon steel welding. E6013 electrode can be used with DCEP (Reverse polarity), DCEN (Straight polarity) and AC polarity.

The arc is stable with all polarity types, DCEN gives deeper penetration compared to DCEP polarity. The depth of weld penetration with AC polarity is moderate. Slag removal is easy with all polarity.E7018 stick welding electrode is used only with DCEP (Reverse polarity) and AC Polarity. Arc is easy to ignite but harder to maintain compared to E6013.

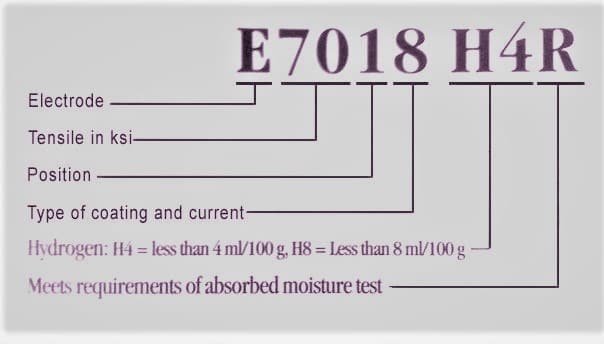

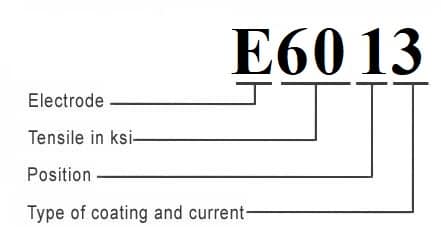

Electrode classification for E7018 & E6013

The Meaning of the E7018 electrode is given in the below diagram. H4R is a supplementary designation used to show the level of weld metal hydrogen that can be produced with this electrode if they are baked and conditioned as per the manufacturer guidelines.

The Meaning of the E6103 electrode is given in the below diagram.

E7018 vs E6013, which is good for root run welding?

Both E6013 and E7018 produce slag and are not mainly designed for root-run weldings like E6010 or E7010 rods. While E6010 and E7010 are cellulose-coated rods and do not produce any slag, E7018 & E6013 produce slag during welding.

Hence, E6010 or E7010 are good choices for root run welding as there will be fewer chances for slag inclusion in the root run welding. Nevertheless, E6013 or E7018 can be used for root run welding. The main point here is the welders skills.

A good welder will make a good weld with any of the electrodes. In the USA many welds are welded with E7018- starting from the root run to the capping passes. E6013 is ideal for new welders as well as for trainees to practice before they work on actual jobs. E7018 are used once they are good to weld using E6013 rods.

E7018 vs E6013, which is stronger?

When we consider the mechanical properties, E7018 or E7024 is the winner. E7018 gives 70KSi (70000 psi) tensile strength compared to 60 Ksi (60000 ksi) of the E6013 electrode.

E7018 having basic coating, and thus gives very good weld toughness properties, in fact, best in all Carbon steel stick welding rods. E7018 welds are more strong compared to E6013 welding rods.