What is ASTM A572 material?

ASTM A572 material specification covers steel of high-strength low alloy (HSLA) structural steel plates used for structure and bridge construction.

The ASTM A572 specification is the Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel for plates used in general construction and structural applications.

ASTM A572 specification has five material grades having minimum yield strengths of 42, 50, 55, 60, and 65 ksi, respectively.

Chemical properties of ASTM A 572

The chemical properties of Grade 42 are:

| C | Mn | P | S | Si |

|---|---|---|---|---|

| 0.21% | 1.35% | 0.030% | 0.030% | 0.15-0.40% |

The chemical properties of Grade 52 are:

| C | Mn | P | S | Si |

|---|---|---|---|---|

| 0.23% | 1.35% | 0.030% | 0.030% | 0.15-0.40% |

The chemical properties of Grade 55 are:

| C | Mn | P | S | Si |

|---|---|---|---|---|

| 0.25% | 1.35% | 0.030% | 0.030% | 0.15-0.40% |

The chemical properties of Grade 60 are:

| C | Mn | P | S | Si |

|---|---|---|---|---|

| 0.26% | 1.35% | 0.030% | 0.030% | 0.40% |

The chemical properties of Grade 65 are:

| C | Mn | P | S | Si |

|---|---|---|---|---|

| 0.26% | 1.35% | 0.030% | 0.030% | 0.40% |

Mechanical properties:

| Grade | Yield Point (ksi) | Tensile Strength (ksi) | % Elongation |

| 42 | 42 | 60 | 20 |

| 50 | 50 | 65 | 18 |

| 55 | 55 | 70 | 17 |

| 60 | 60 | 75 | 16 |

| 65 | 65 | 80 | 15 |

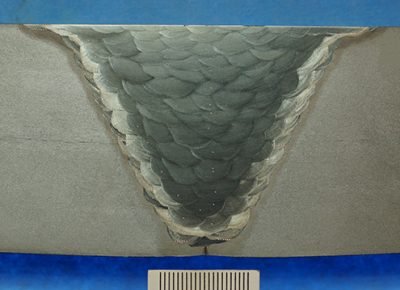

SMAW, TIG MIG welding of ASTM A 572

👉👉Get Audel Welding Pocket Reference Book👉👉

The selection of suitable welding electrodes is very essential for the welding of this grade. ASTM A 572 grades 42, 50 & 55 can be welded with SMAW or stick welding rod E7018 (SFA 5.1). Welding of ASTM A572 Grade 60 & 65 shall be carried out using the E8018-G electrode.

TIG or MIG welding of ASTM A 572 grades 42, 50 & 55 are made with ER70S-6 and for grades 60 & 65, it is welded using ER80S-G.

FCAW welding is carried out with E71T-1M to have good mechanical properties. For grades 60 & 65 FCAW welding is carried out using E8XTX-X as per SFA 5.29.

Note: When selecting consumables with G classification, find the one with minimum additional alloying elements. Electrode with G classification is available in various alloying element combinations.

Preheat/ Interpass temperature of ASTM A 572

Preheat temperature must be applied when welding thick parts of ASTM A572. The grade of ASTM A572 is also important for determining the preheat temperature.

For example, for ASTM A572, Grades 42, 50, 55- Preheat temperature of 110°C (225°F) to be applied for a thickness more than 2.5 inches (65 millimeters), for thickness above 1.5 inches to 2.5 inches preheat temperature of 65°C (150°F) to be applied. Less than 1.5 inches of preheat to ambient temperature is sufficient.

A572, Grades 60 & 65 need higher preheat temperatures. For thickness above 0.75 inches (18 mm) minimum, preheats of 65°C (150°F) are to be applied.

Preheat temperature of 150°C (300°F) to be applied for a thickness of more than 2.5 inches (65 millimeters), for a thickness above 1.5 inches to 2.5 inches preheat temperature of 110°C (225°F) to be applied.

PWHT Temperature and time for ASTM A 572

Post Weld Heat Treatment (PWHT) of ASTM A 572 is 1094 °F-1110°F (590-600°C). The micro-alloyed grades of ASTM A 572 can results in changes in mechanical properties so it is recommended to follow plate manufacturer guidelines.