Welding ASTM a387 grade 11 (EN 1.7335, DIN 13CrMo4-5)

This article covers the guidelines for Welding ASTM a387 grade 11 (EN 1.7335, DIN 13CrMo4-5).

A387 Grade 11 Class 2 is a chrome-molybdenum steel that is known for its high strength and elevated temperature properties, particularly in the oil, gas, and chemical industries.

It is commonly used in the construction of pressure vessels (columns, reactors and tanks, for example) operating at high temperatures. The steel’s high chromium content also gives it good resistance to corrosion and oxidation.

ASTM A387 Grade 11 Material

ASTM A387 Grade 11 is a chrome-molybdenum alloy steel that is commonly used in the oil and gas, petrochemical, and power generation industries.

This material is known for its high strength and excellent corrosion resistance, making it ideal for use in high-temperature and high-pressure applications.

Read more: ASTM A387 Grade 11 Material Complete Properties.

In this article, we will take a closer look at the properties, composition, and welding guidelines of ASTM A387 Grade 11.

ASTM A387 Grade 11 Class 1 and Class 2 P Number & Group Number

ASTM A387 Grade 11 Class 1 and Class 2 material P Number is 4 and Group Number 1 as per ASME Section IX. The UNS Number for ASTM A387 Grade 11 material is K11789.

ASTM A387 Grade 11 Class 1 and Class 2 Chemical & Mechanical Properties

Chemical & Mechanical Properties of ASTM A387 Grade 11 Class 1 and Class 2 are listed in the below table:

| Chemical Component | Composition (Heat analysis) | Composition (Product analysis) |

| Carbon (C) | 0.05-0.17% | 0.04-0.17% |

| Manganese (Mn) | 0.4-0.65% | 0.35-0.73% |

| Phosphorus (P) | 0.025% | 0.025% |

| Sulfur (S) | 0.025% | 0.025% |

| Silicon (Si) | 0.5-0.8% | 0.44-0.86% |

| Chromium (Cr) | 1.00-1.50% | 0.94- 1.56% |

| Molybdenum (Mo) | 0.45-0.65% | 0.4-0.70% |

| Others | Trace elements | Trace elements |

| Mechanical Properties | Value (Class 1) | Value (Class 2) |

| Tensile Strength | 55- 80 Ksi (415-585 MPa) | 75-100 Ksi (515-690 MPa) |

| Yield Strength | Minimum 35 Ksi (240 MPa) | Minimum 45 Ksi (310 MPa) |

| Elongation | min 18% in 8-inch & 22% in 2-inch | min 18% in 8-inch & 22% in 2-inch |

| Toughness | Not specified | Not specified |

Stick (SMAW) Welding ASTM A387 Grade 11

Stick welding, also known as Shielded Metal Arc Welding (SMAW), can be used to weld ASTM A387 Grade 11.

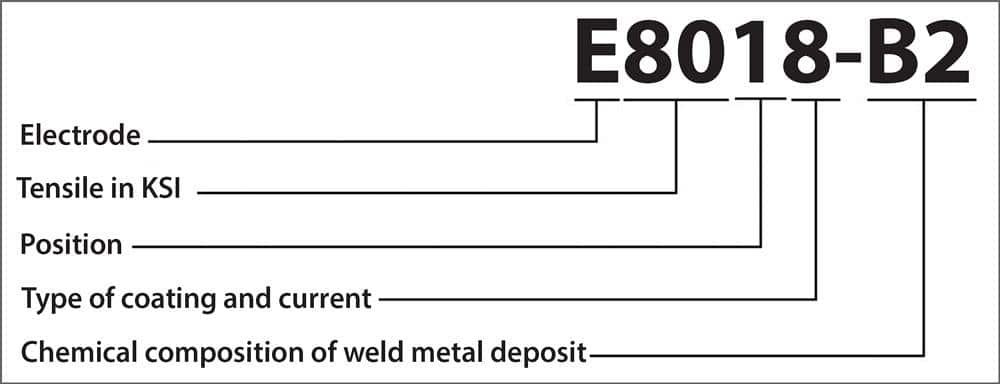

The welding electrode should be of the same composition as the base metal. The best stick welding (SMAW) rod for welding ASTM A387 Grade 11 Class 1 and Class 2 are:

- ASTM A387 Grade 11 Class 1 welding: E8016-B2, E8018-B2 (AWS A5.5 Specification)

- ASTM A387 Grade 11 Class 2 welding: E8016-B2, E8018-B2 (AWS A5.5 Specification)

Use low hydrogen welding electrode and make sure to properly bake them before use. A high level of weld deposit hydrogen can easily create hydrogen cracking in this material.

Preheating and post heating for welding ASTM A387 Grade 11.

Apply a preheat temperature of 325 to 375°F (160°C to 190°C) when welding ASTM A387 Grade 11 material. Restrict the maximum interpass temperature for welding ASTM A387 Grade 11 to 375°F (190°C).

ASME Section VIII Division 1 recommends a preheat temperature of 250°F (121°C). But it is good to keep a higher preheat to ensure hardness control.

Post weld heat treatment (PWHT) for ASTM A387 Grade 11 Class 1 and Class 2

Post weld heat treatment or PWHT for ASTM A387 Grade 11 Class 1 and Class 2 is carried out at a temperature of 1275± 25°F (690± 15°C). PWHT holding time is 1 hour per inch for thickness as per ASME Section VIII Division 1.

For more details refers ASME Section VIII Division 1 UCS-56.

TIG Welding ASTM A387 Grade 11

TIG Welding ASTM A387 Grade 11 with ER80S-B2 filler wire rod: TIG welding, also known as Gas Tungsten Arc Welding (GTAW), can be used to weld ASTM A387 Grade 11 using the ER80S-B2 filler wire rod.

This filler wire is specially designed for welding low alloy steels and it’s composition is similar to ASTM A387 Grade 11. The use of this filler wire will ensure that the welded joint has similar mechanical properties as the base metal.

When TIG welding ASTM A387 Grade 11, it’s important to use pure argon as the shielding gas. Argon is an inert gas that is commonly used in TIG welding to protect the weld pool and the electrode from oxidation.

The low chromium content of ASTM A387 Grade 11 means that purging is not required, but it’s still important to make sure that the welding area is clean and free of contaminants to ensure a high-quality weld.

The use of the right filler wire and shielding gas, and proper welding techniques, will ensure that the welded joint has similar mechanical properties as the base metal and will produce high-quality welds.

MIG Welding ASTM A387 Grade 11

MIG welding, also known as Gas Metal Arc Welding (GMAW), can be used to weld ASTM A387 Grade 11 using the ER80S-B2 (AWS A5.28) mig wire.

This wire is specially designed for welding low alloy steels and it’s composition is similar to ASTM A387 Grade 11. The use of this wire will ensure that the welded joint has similar mechanical properties as the base metal.

When MIG welding ASTM A387 Grade 11, it’s important to use a 75-25 argon+CO2 gas mixture as the shielding gas.

The use of argon and CO2 mixture is a common way to protect the weld pool and the electrode from oxidation and to stabilize the arc. The CO2 in the mixture increases penetration.

It is also important to apply a welding preheat temperature in the range of 325 to 375°F (160°C to 190°C) before starting the welding process.

Preheating the material before welding helps to reduce the chances of cracking and warping by equalizing the thermal expansion and contraction of the material.

It’s important to note that the heat input should be controlled during the welding process, and a proper inter-pass temperature should be maintained to control final weld metal microstructure. And it’s important that the welder to have proper training and experience in MIG welding for achieving the best results.

SAW Welding ASTM A387 Grade 11

SAW welding or Submerged Arc Welding (SAW) of ASTM A387 Grade 11 is carried out using the F8P2-EG-B2 Flux-wire combination.

This flux-wire combination is specially designed for welding low alloy steels and it’s composition is similar to ASTM A387 Grade 11.

A summary of welding consumables required for welding ASTM A 387 Grade 11 using stick welding, TIG welding and SAW welding is given in the below table.

| Material | Process | Classification | Welding Polarity |

ASTM A387 Grade 11 (P11) | SAW (Flux/Wire) | AWS A5.23: F8P2-EG-B2 | AC |

| ASTM A387 Grade 11 (P11) | SMAW | AWS A5.5 E8016-B2/ E8018-B2 | AC, DCEP |

| ASTM A387 Grade 11 (P11) | GTAW | AWS A5.28 ER80S-B2 | DCEN |

Welding ASTM A387 Grade 11 to AISI 321 or AISI 347 Stainless Steel

Welding ASTM A387 Grade 11 to AISI 321 or AISI 347 Stainless Steel can be achieved through various welding methods, such as SMAW (Stick welding), TIG and MIG welding. Each method requires a specific filler metal and welding wire rod to ensure the welded joint has similar mechanical properties as the base metal.

SMAW (Stick welding) can be achieved using E309LMo or ENiFeCr-3 filler metal. These filler metals are suitable for welding dissimilar metals such as carbon steel to stainless steel.

E309LMo is a low-carbon, stainless steel electrode that is ideal for welding low-alloy steels to stainless steels. ENiFeCr-3 is a nickel-iron electrode that is ideal for welding dissimilar metal.

TIG and MIG welding can be achieved using ER309LMo or ERNiCr-3 welding wire rod. These wire rods are suitable for welding dissimilar metals such as carbon steel to stainless steel.

ER309LMo is a low-carbon tig wire that is ideal for welding low-alloy steels to stainless steels. ERNiCr-3 is a nickel-chromium wire that is ideal for welding dissimilar metal.

It’s important to note that no preheat is required when welding AISI 321 or AISI 347 Stainless Steel.