What is E8018-B2 Electrode?

E8018-B2 is a low-hydrogen electrode that produces weld metal that nominally contains between 1.00–1.50% chromium and 0.40–0.65% molybdenum.

E8018-B2 is designed to give a weld deposit for high-temperature application with matching chemical & mechanical properties for Cr-Mo materials usually known as 1 and 1 1/4 Cr-1/2 Mo steel (1.25Cr-0.5Mo) steel.

E8018-B2 electrode coating type is basic iron powder. The equivalent of E8018-B2 as per ISO 3580A is ECrMo1.

E8018-B2 vs. E8018-B2L

E8018-B2 has a low carbon classification as E8018-B2L. The E8018-B2 has a carbon content of up to 0.08% while E8018-B2L, the carbon content is allowed a maximum of 0.05% only.

So, the stick welding electrode with ‘L’ are having extra low carbon. Having low carbon will increase the weld metal ductility but decreases the elevated temperature strength, hardness, and creep resistance.

It is advised to use E8081-B2 instead of E8018-B2L for high-temperature application as its creep strength is more due to its high carbon percentage.

Related Reading: ER80S-B2: Complete information you are looking for.

E8018-B2 Welding Rod Material Specification

E8018-B2 electrode is supplied as per AWS A5.5 or ASME Section IIC, SFA 5.5. The equivalent of E8018-B2 as per EN or ISO standard according to EN 1599:1997 is E CrMo1 B 4 2 H5.

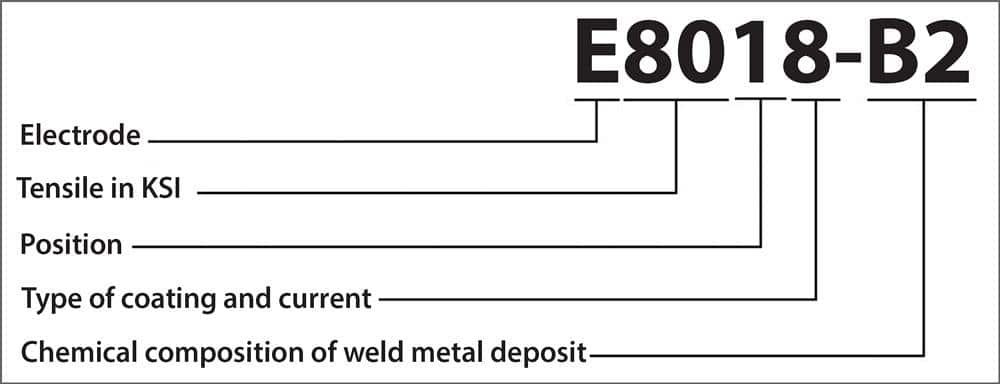

The TIG equivalent wire of E8018-B2 is ER80S-B2 as per SFA 5.28. The meaning of the E8018-B2 electrode is explained in the below figure.

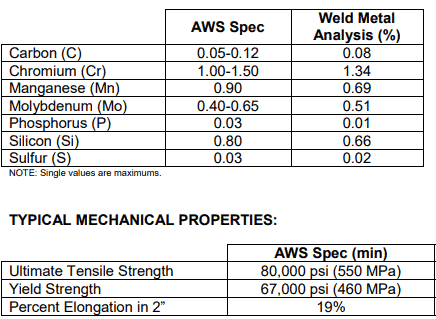

Chemical and mechanical properties of E8018-B2

The chemical and mechanical properties of E8018-B2 are shown in the below table.

The tensile strength of E8018-B2 is 80 Ksi or 550 MPa and Yield strength is 67 Ksi or 460 MPa.

There are no toughness requirements for the E8018-B2 electrode as the electrode is used for high-temperature applications only while material toughness is a concern in low-temperature service conditions.

E8018-B2 electrode coating

E8018-B2 has a basic coating and is also called low hydrogen electrodes for stick welding application used for welding of Cr-Mo materials.

The main coating elements of these electrodes are calcium carbonates, potassium, and iron powder.

A complete list of major coating elements (excluding alloying elements) used in E8018-B2 Welding rod are:

- Limestone

- Titanium dioxide

- Sodium & Potassium silicate

- Quartz

- Fluorides

- Hydroxyethyl Cellulose

- Carboxymethyl Cellulose

The minerals present in the coating resist moisture absorption and due to this these electrodes are called low hydrogen electrodes.

Use of E8018-B2 Electrode

E8018-B2 electrode is used for welding of 1.25Cr-0.5Mo steels such as ASTM A335 Gr. P11, A387 Grade 11, A193 Gr. B7, A217 Gr. WC6.

The electrode is also used for the dissimilar welding of Cr-Mo steels such as 1.25Cr-0.5Mo to carbon steel or 0.5Mo to carbon steel material.

Storage and Baking/ conditioning of E8018-B2 electrode

E8018-B2 electrode being a low hydrogen electrode requires electrode baking prior to use. Click here to learn about E8018-B2 electrode baking requirements.

E8018-B2 electrode polarity

Being a basic type electrode, the E8018-B2 electrode is used with Direct current electrode positive (DCEP) and Alternating current (AC) polarity. DCEP gives a smooth arc and minimal spatters with optimized welding parameters.

DCEP also offers higher penetration and good appearance welds. AC welding polarity is generally used with welding generator used on site welding.

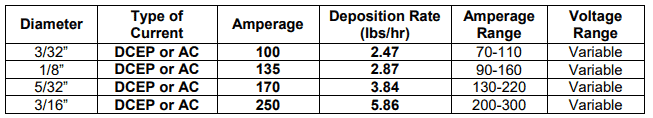

Welding parameters for E8018-B2

The typical value of current for E8018-B2 is shown in the below table. 3/32 inch electrode requires generally 100 amperes and /8 inch runs well on 130-140 ampere range.

Similar Posts:

- E8010, E8010-P1 (E5510-P1) welding rod, MTC, meaning, specification and chemical-mechanical properties

- How to Choose the Right Stick Welding Electrode and Rod Type

- E7018-1 or E4918-1-H4 electrode specification, meaning, chemical & mechanical properties with MTC

- E7024, E7024-1 Electrode Specification & its meaning