Meaning of E7018 Welding Rod

E7018 rod is one of the most frequently used SMAW/ stick welding low hydrogen electrodes for mild steel, cast steel and Carbon Steel welding. The E7018 rod coating is made with inorganic coverings that contain minimal moisture thus providing a weld deposit with the lowest hydrogen in weldment, thus giving the name to these electrodes as Low Hydrogen Electrodes.

E7018 electrodes also contain a relatively high percentage of iron powder added into the coating which gives higher productivity as you will get more weld deposits compared to E7015 electrodes of the same diameter.

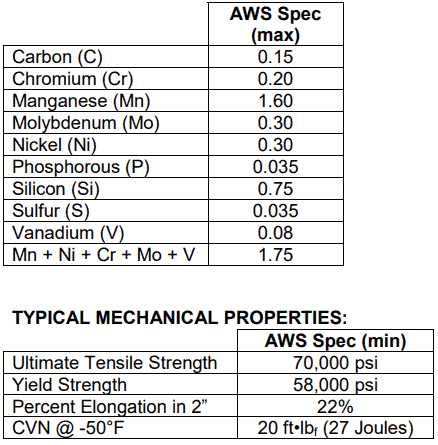

Chemical and mechanical properties of E7018 as per AWS A5.1

The chemical and mechanical properties of the E7018 stick welding rod are given in the below table. The values are the maximum chemical percentage allowed for each element. For the mechanical properties of E7018, the values are the minimum required.

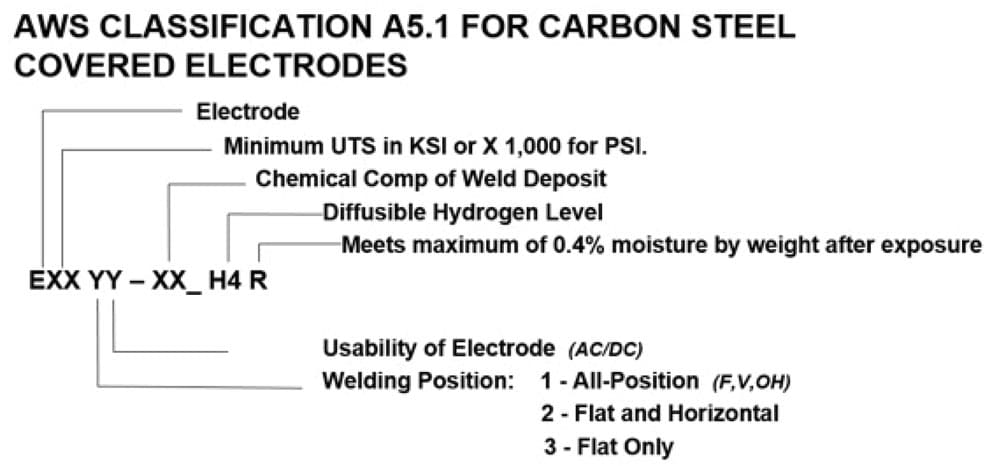

E7018 electrode Specification & classification

E7018 electrodes are classified according to ASME Section IIC, 5.1 Specification for Carbon steel electrodes for Shielded metal arc welding. Similar to other welding electrodes, each digit in the E7018-H4 electrode has its own meaning.

These digits give very valuable information about this electrode as given below:

- ‘E’ stands for Electrodes for SMAW or Stick welding.

- The next two digits i.e. ’70’ indicate the tensile strength of the weld deposit is 70 KSI or 70000psi.

- The next digit ‘1‘ indicates it is an all-position electrode.

- The last digit ‘8’ indicates it is a basic coated electrode with an improved deposition rate ( because of added iron powder in the coating ) and low hydrogen type.

E7018 electrode Optional Supplemental Designators

Now, there is an additional supplementary designation for E7018. When it is E7018 -1, So, hereby ‘1’, it means that it is suitable for low-temperature application welding as the weld deposit has improved notch toughness or impact properties.

Sometimes, an Optional Supplemental Designators suffix ‘H4’ or ‘H8’ is used which indicates possible Hydrogen content in the weld:

- H4 = Less than 4 ml/100 grams.

- H8 = Less than 8 ml/100 grams

- H16 = Less than 16 ml/100 grams.

Sometimes a suffix R is used which means the electrode meets the requirement of the absorbed moisture test. Hydrogen available in electrode coating or in the atmosphere finds its way into weld metal from moisture in the welding consumable so baking of E7018 electrode is very important. (Especially if the electrodes were left in the atmosphere, they will absorb moisture).

Electrodes shall be kept sufficiently hot in a portable oven to eliminate the chance of any additional moisture getting into the electrode.

Click here to know about the Electrode Baking requirements for SMAW/ Stick Welding Electrodes.

The diffusible hydrogen into the weld metal if presented in sufficient quantity, will cause hydrogen cracking or cold cracking as the hydrogen atoms will get trapped while the weld will cool fast due to rapid cooling caused by welding.

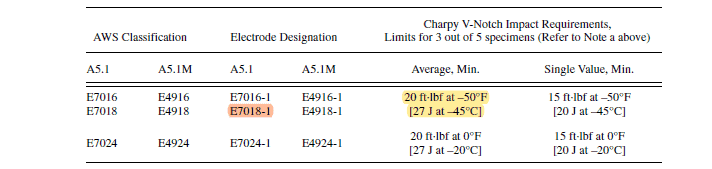

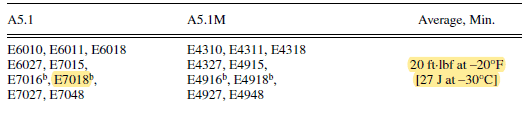

Charpy V-Notch Impact (toughness) Requirements for E7018 type electrode

E7018 Stick welding electrode requires to have minimum V-Notch toughness values of 20 ft·lbf at –20°F (27 J at –30°C) as per AWS A5.1 specification. Electrodes with the optional supplemental designations which is E7018-1 shall meet the lower temperature impact requirements of 20 ft·lbf at –50°F (27 J at –45°C).

General recommendation to avoid Hydrogen Cracking

Once the steel has been selected and purchased for welding, the options available to counter the possibility of hydrogen cracking include:

- Minimize weld joint restraint.

- Avoid notches in the area of the weld.

- Use a low hydrogen process.

- Use low hydrogen consumables and ensure their proper storage.

- Use high arc energy to reduce the cooling rate (but this may reduce other properties such as strength and toughness).

- Use preheat (and post-heat); its main function is to slow down the cooling rate below 212°F (100°C) and give more time for hydrogen to diffuse out.

- It’s recommended to provide a post-heat for 15 to 30 minutes period to allow hydrogen diffusion after welding finish @ 300 to 350 Deg C.

- Target to avoid hard microstructure – if weld cooling rates are high, detrimental phases such as martensite & bainite can form in the weld and Heat Affected Zone or HAZ which are prone to Hydrogen cracking.

- Minimize restrain to allow residual stress accommodation.

E7018 Welding electrode Polarity

E7018 electrodes are can be used with AC and DCEP polarity. The potassium-based coating allows good arc characteristics using AC as well as DCEP current with E7018 electrodes.

Related Post: Types of Polarity in Welding.

E7018 (E4918) vs E7018-1 (E4918-1)

Both E7018 & E7018-1 are carbon steel welding rod having the same mechanical strength. The only difference is the weld toughness. E7018-1 is having higher Charpy impact toughness compared to E7018 welding rod.

In E7018-1 H4 (E4918-1), ‘1’ refer to the lower weld metal toughness properties. The average impact toughness (CVN) requirement for E7018-1 H4 (E4918-1) is 20 ft·lbf at -50°F (27 J at –45°C) as shown in the below abstract taken from ASME Section IIC, SFA 5.1.

While the toughness requirement for E7018 is 20 ft·lbf at -20°F (27 J at –30°C) compare to E7018-1. So, the main difference between the E7018-1 H4 (E4918-1) and E7018 (E4918) is the impact toughness test temperature.

E7018 vs E7024 Electrode

E7024 electrodes are not suitable for all positions, as the number ‘2’ indicates, but only for horizontal and flat/plane positions while E7018 is all position electrodes. E7018 is low hydrogen potassium-based coating while E7024 is a rutile titania coating. Click here to learn deep about the E7024 electrodes.

The ASME Section IX, F numbers are different for E7018 & E7024. E-7024 (Rutile iron powder coating) has F No. 1 while E-7018 has F no. 4 (Low hydrogen-potassium-iron powder coating).

The similarities between E7018 & E7024 are:

- Both are having iron powder coating.

- Both have 70ksi minimum tensile strength.

E7018 welding rod uses

E7018 is a Stick welding rod used for welding plain carbon steel/ mild steel, carbon steel, and low alloy steel welding. E7081-1 with supplement designation is used for welding of low-temperature applications.

This rod is widely used for welding carbon steel having strength in the range of 70 Ksi. Due to the low carbon in the rod, there are no weldability issues when performing stick welding using the E7018 rod.

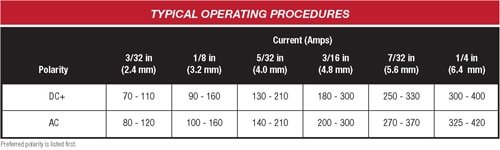

Selection of current for E7018 Electrode

The correct welding amperage (current) setting mainly depends on the electrode diameter used. For example, a 1/8-inch 7018 rod runs well from 90 to 150 ampere, while a 3/16 inch 7018-rod welds at currents up to 300 amperes.

The below tables gives the recommended welding amperage for E7018 electrode diameter 3/32, 1/8, 5/32, 3/16, 7/32 & 1/4 inch sizes.

MTC/ CMTR for E7018 Electrode

An MTC/ CMTR for the E7018 electrode contains the results of deposit weld metal chemical analysis & mechanical properties such as yield & tensile strength, percentage elongation, and toughness values.

This is a 3.1 test certificate containing actual test results for the E7018 electrode.

Click here to download MTC for the E7018 electrode. E7018 MTC.pdf

Why E7018 Welding Rod is called Low-Hydrogen Electrode?

The E7018 rod coating is made with inorganic coverings that contain minimal moisture thus providing a weld deposit with the lowest hydrogen in weldment, thus giving the name to these electrodes as Low Hydrogen Electrodes.

Low-hydrogen electrode coverings can be designed to resist moisture absorption for a considerable time in a humid environment so, even if they are kept in a humid place, they will need significant time to absorb the moisture.

Click here to Learn What is E6010 & its hidden coating elements & E6010 Classification.

E7018 Welding Rod Features

E7018 electrodes also contain a relatively high percentage of iron powder added into the coating which gives higher productivity as you will get more weld deposits compared to E7015 electrodes of the same diameter.

Note (Don’t try it on the actual job): For understanding resistance to moisture absorption, dip an E7018 electrode in water for a few minutes and weld. You will not see any porosity in the weld. Now, try a similar experiment with E7010 or E6013 types & you will observe significant weld porosity.

Due to the thick covering and deep cup produced at the arcing end of the electrode, iron powder electrodes can be used very effectively with a “drag” technique. This technique consists of keeping the electrode covering in contact with the workpiece at all times, which makes for easy handling.

However, a technique using a short arc length is preferable if the 3/32 inches or 1/8 inches (2.5 mm or 3.2 mm) electrodes are to be used other than flat or horizontal fillet welding positions or for making groove welds.