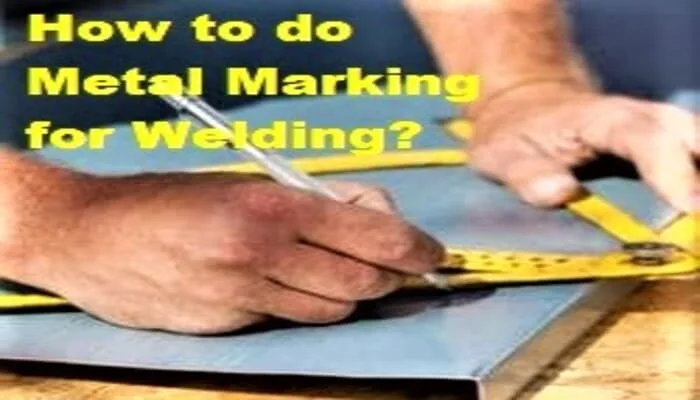

Soapstone is a soft, dense material that is perfect for use in welding applications. Soapstone for welding applications is a quick and reliable technique to serve different objectives as covered in this article.

When used to mark and fit welding assemblies, it provides a visible line that can be easily seen by the welder or fabricators during assembly and tacking.

This makes it much easier to achieve a precise fitment of different parts, which is essential for the accurate dimensional fabrication of components.

Soapstone or chalk is also very safe to use, as it does not produce any dangerous fumes or chemicals in welding applications.

Using a pencil or marker is not a viable option in welding as mostly steel plates surface will not provide sufficient contrast to lines made by the pencil. Here, using soapstone is the best and most reliable option.

So, What is Soapstone?

Soapstone is a metamorphic rock that gets its name from its soapy feel. The rock is composed of talc, chlorite, and serpentine, which give it a soft texture.

Soapstone is a natural stone that has been used for centuries for a variety of purposes. It gets its name from its soapy feel and its ability to absorb oils. Soapstone consists mostly of talc with varying amounts of chlorite and amphibole minerals.

Soapstone has been used for centuries to make sculptures, vases, bowls, and other objects. The rock is also used in the construction industry and for making countertops and flooring tiles.

How is Soapstone Used in Welding?

Welders use soapstone to mark the fitup, center marking, and cutting lines on metal pieces that they are joining together.

This helps them to get a precise weld and avoid any mistakes. The soapstone leaves a visible line that can be easily seen against the metal background.

Fabricators and fitters also use soapstone to mark lines on the metal pieces they are working with. This allows them to cut the metal precisely along the line without any mistakes.

Soapstone is a very useful tool for welders, fabricators, and fitters because it is easy to carve and leaves a visible line.

Use of Soapstone in Welding for Gas Cutting

Soapstone for welding and gas cutting has different uses. It can be used to mark the cutting path on a plate of metal. This makes it easy to cut the metal accurately and eliminates the need for punch marking.

Fabricators use soapstone to mark the cutting lines on plates or pipes as this marking will not burn during cutting which is otherwise the case if a white paint marker is used.

Marking using soapstone is fast and can also be erased easily if any correction is needed. This is the opposite if marking is made using punching or paint marker that is difficult to erase.

Soapstone is ideal for use in welding because it is easy to mark on a plate. The soapstone quickly and accurately shows the cutting path, making it much faster and more accurate than using a punch mark. This eliminates the need for costly and time-consuming mistakes when cutting metal plates.

Use of Soapstone in Welding by Fitters

Soapstone has several properties that make it useful for welding. Fitters use soapstone to inscribe the layout for critical assemblies, the layout of rolling parts, or bending jobs.

Fitters or fabricators also use soapstone to mark the centerline, endpoints, and label the individual’s part locations before they are tack welded.

The soapstone marking is easily removable and not produces any dust. it is safe to use and cloths friendly. Just shake it up if it sticks to the clothes.

Use of Soapstone in Welding by Welders

Welders have long used soapstone to mark their work. The soft rock is easy to carve, and it holds chalk well. This makes it ideal for writing on metal surfaces.

Welders use soapstone to identify their work, mark bad weld locations, and keep track of welding done by different welders.

Bad welds are often marked with a piece of soapstone so that they can be repaired later. By marking these locations, welders can avoid making the same mistake twice.

Soapstone makes it easy to create sharp lines and shapes that are visible in greyish welding areas. Soapstone is also non-toxic and safe to handle, making it a good choice for use around welding.

Use of Soapstone by Welding Inspectors

Welding inspectors rely on soapstone to help them do their job correctly and efficiently. By using soapstone, they are able to quickly identify areas that need to be repaired or improved.

Welding inspectors use soapstone to mark faulty welds, identify weldments for acceptable-not acceptable, and highlight welding defects for repairs.

Marking made by welding inspectors works as a reference for repair welders to quickly repair the unacceptable welding. The welding inspector then re-verify those locations.

Using soapstone is beneficial to mark repair instead of using paints. If paints are used, they are prone to create welding porosity as they contain oily substances. While this is not a concern with soapstone marking.

Soapstone for Welding

Soapstone is available in both round and rectangular shapes. It can be purchased from Amazon or other retailers. When using soapstone for welding, it is important to use a holder to keep the stone in place. Soapstone is easy to carry and makes marking easy.

You can find both round and rectangular shapes to suit your needs, and they’re very easy to carry around with you thanks to the holder. Plus, marking is a breeze with this soapstone.