Maximum Wind Velocity at site of Welding

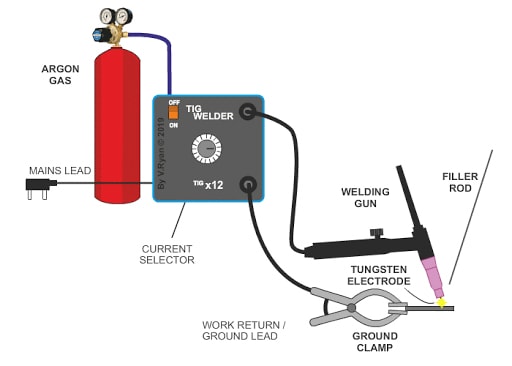

MIG- MAG (GMAW), TIG (GTAW), EGW, or FCAW-G welding processes uses externally supplied shielding gas to protect the weld puddle. Performing these welding processes in open will cause the gas blanket disturbed and leads to welding porosity & oxidation.

Hence, these above discussed welding processes (TIG, MIG, FCAW-G & EGW) shall not be carried out in a draft or wind. If required, the welding surrounding shall be covered by a shelter.

The shelter or any other arrangement shall be adequate to reduce the wind speed in weld vicinity to a maximum of 5 mph (8 km/h).

So, the wind velocity shouldn’t be more than 5 miles per hour or 8 kilometers per hour as specified in AWS D1.1 in the welding area or weld vicinity.

Other welding codes such as ASME or EN/ ISO are silent on exact maximum wind velocity. Rather, these standards call for welding conditions protected from direct air drought.

Minimum Ambient Temperature for Welding

Any Welding work should not be done under the following weather conditions pertaining to temperature:

- When the ambient temperature is lower than 0°F (-20°C), or

- When welding areas are wet or subjected to rain, snow, or

- High wind speeds (velocity), or

- When welder are exposed to adverse weather (snowy, storm) conditions.

NOTE: Here, Zero °F (-20°C) does not mean the ambient environmental temperature, but the temperature in the immediate nearby the welding.

The ambient environmental temperature may be below 0°F (-20°C), although having a covered area or heating arrangement near the weld can help to maintain temperature for the welding joint above the minimum required.

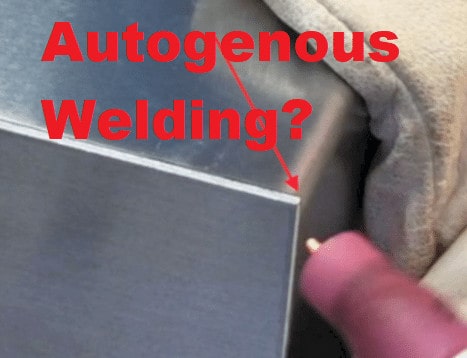

Does Stick Welding or SMAW safe to carry out in open area, Is it safe to weld in windy?

In the Stick Welding or SMAW process, the shielding gases are released by the burning of electrode coating.

The gases produced due to intense burning heat release a high gaseous pressure, which makes Stick welding the least prone to air blow or wind effects on welding arc.

Although, too high wind can make the welding arc unstable due to improper gas blanket. So, Stick welding or SMAW also shouldn’t be done in the high windy conditions.

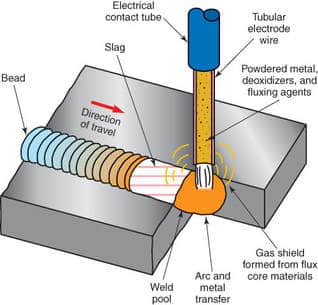

What about Gas Shielded Metal Arc processes?

Gas Shielded Metal Arc processes such as GMAW- MIG & MAG and FCAW use externally supplied shielding gases.

These gases provide a basic gas shielding without a strong shielding effect like in Stick Welding, SMAW. Hence, they are easily losing their gas shielding blanket if exposed to high wind conditions.

Thus, GMAW & FCAW should be carried out in-house or when proper blankets or welding area coverage is available on the sites.

in GMAW & FCAW, the gas shielding at the point of welding is to be protected from the wind to prevent interruption in shielding and resulting contamination of the weld by the atmosphere.

Stick Welding in the Wind

Stick Welding or SMAW welding can be carried out in wind or windy weather up to 20 mph without any adverse effect on the weld quality.

The shielding created by the electrode coating has very high gas pressure as these gases are produced in high quantity during electrode burning.

However, higher wind speed tends to influence the gas shielding blanket created by the electrode coating and is prone to have weld porosities.

Other welding processes such as TIG, MIG, or PAW must not be carried out in the wind as they depend upon an externally supplied shielding gas with low pressure.

Stick Welding in the Rain or High Humidity

Any welding process either stick welding or TIG, MIG or FCAW shall not be carried out in the exposed rainy conditions.

The obvious reason is- the wet surface will create weld porosity. Apart from there, it poses an electric hazard if the power source can get water inside it or there is no proper insulation that can protect the welder.

If there is right protection of welding machine and welder, and welding is essential to be carried out in the rainy weather, then in such cases- stick welding is a better option to perform emergency welding work in the rain.

but try to make the work minimal and complete the full welding in the right welding conditions so that the weld integrity can be of high quality.