What is Open Circuit Voltage or OCV?

Welding processes require voltage in the range of 15 to 40 volts, and current in the range of 50 Amp to 400 Amp, normally for Stick Welding or SMAW, Gas Tungsten Arc Welding (GTAW), MIG-MAG, and Flux-cored arc welding or FCAW.

But what about the Voltage when there is no Welding but the Welder is running?

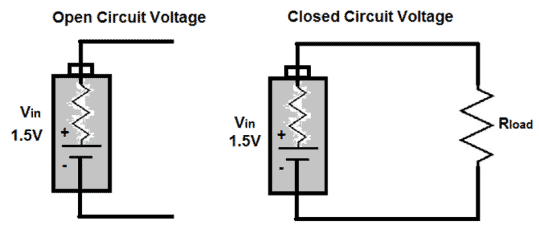

Open Circuit Voltage, also called OCV in Welding refers to the voltage when there is no arcing. The Welder supplies the voltage with zero amperage.

When the welder switches on the welding machine, and without making any actual welding, there remains the OCV between the negative and positive terminal.

As you can see in the below example, Open Circuit Voltage means the voltage when the circuit is open which means no welding.

The closed-circuit voltage takes place during welding & is explained further in this article.

Why OCV values kept maximum 80 Volts?

As we know, the maximum safe limit of voltage is 80 volts for a human body. A higher voltage above this limit can be lethal for living organisms.

Simply, the higher the open-circuit voltage or OCV, the easier it is to strike an arc because of the initial higher voltage pressure, but more risk to electric shock.

Being 80 Volts is a safe limit of electric hazard for humans, welding power sources are designed to have a maximum OCV of 80 Volts.

What is the maximum safe open circuit voltage for Welders?

The maximum safe open circuit voltage for welders is 80 volts. This is the maximum voltage a human body can be safe under ideal conditions excluding a wet area or not using proper insulation.

Duty cycle in welding and how to calculate duty cycle of welding machine?

How to check OCV on welder/ Welding Machine?

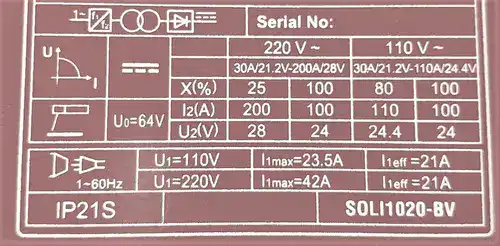

On a welder, OCV can be find on the rating plate affixed to the welder/ welding machine. Refer the below snap of a welder rating plate.

Here, U0 refer to the OCV of the welder. So, for this example open circuit voltage or OCV is 64 volts.

As all welders have this rating plate put by the manufacturer, you can easily find OCV for any welder/ welding machine.

What is the value of open circuit voltage (OCV) of a welding transformer/ Welding machine?

Typically values of open circuit voltage (OCV) for welders/ welding machines are within the range of 50V – 80V for Stick Welding or SMAW, MIG-MAG, Flux cored arc welding or FCAW & Submerged Arc Welding (SAW).

An open circuit voltage (OCV) within the range of 50 to 80 volts helps in the easy striking of the arc, thus benefiting the welders in an easy weld start.

open circuit voltage for arc welding is of the order of 50 to 80 Volts that makes easy to strike an arc.

What is close circuit or operating voltage (OCV)?

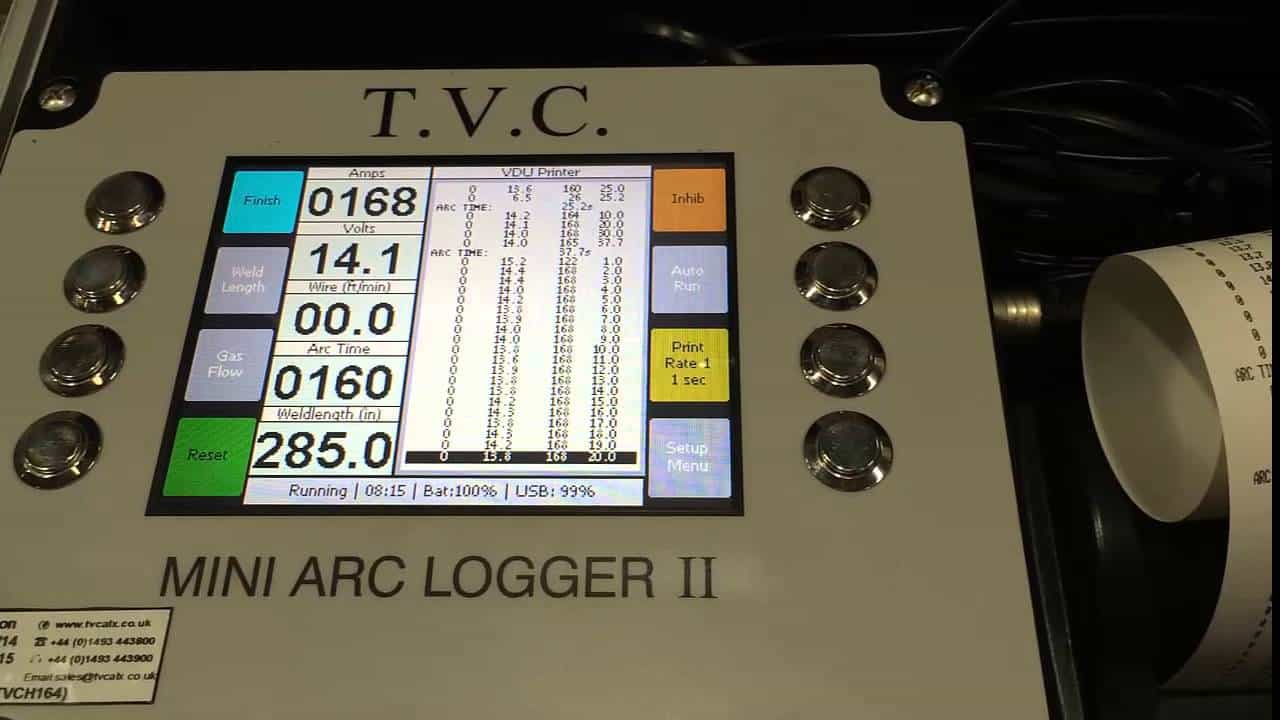

Closed circuit voltage (OCV) is the voltage measured across the arc during welding that means the voltage found among the work-piece and the electrode holder during welding.

It will vary depending upon type of electrode, polarity, arc length & current type. Typically, the closed circuit voltage is runs between 15 – 40 volts.

How is open circuit voltage OCV different from Welding Voltage?

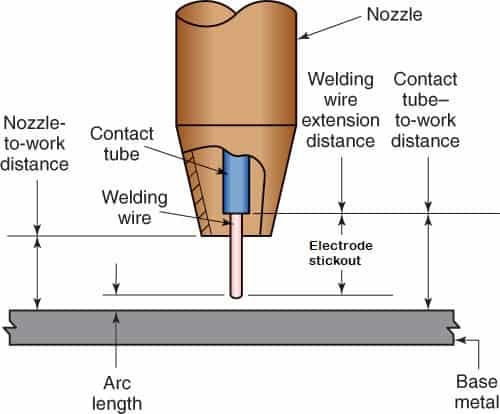

Open Circuit Voltage should not be confused with Welding Voltage (V). When we say welding voltage it refers to the voltage that runs from the welding electrode to the workpiece during welding.

Simply, it is the voltage we can measure during welding between the workpiece and welding rod during welding is ON.

This voltage is lower than the open-circuit voltage (OCV) as you can observe during welding.

In stick welding, we use around 15 to 22 volts and in MIG we use around 17 to 25 volts typically. Welding voltage is affected by arc length, shielding gas, and electrode diameter for example.

What uses a low open circuit voltage to start the arc?

Open-circuit voltage, or OCV, is the voltage between the electrode and workpiece when no welding current is flowing.

In TIG welding, a HF unit is used to start the arc with a low open circuit voltage. The HF unit produces a high-frequency electrical field that ionizes the gas around the electrode, allowing current to flow and starting the arc.

Welding Voltage vs Amperage

Welding voltage and amperage are two important factors that determine the quality of a weld. The right combination of these two factors can result in a strong, and quality welds.

- Voltage values are kept lower due to safety concerns while amperage is high on welding machines to give high heat input within electricity safe limit.

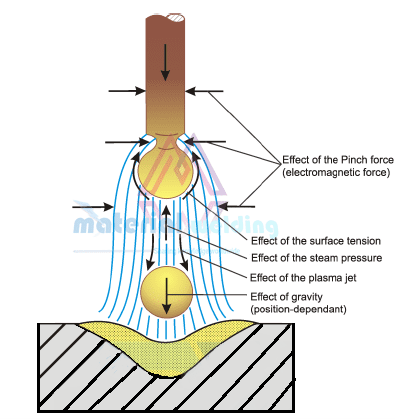

- Voltage is responsible for weld bead width while amperage gives welding penetration depth.

- Manual welding processes such as TIG and Stick welding, relies on constant current type machines to accommodate manual arc length fluctuation while semi-automatic and automatic welders (e.g., MIG and FCAW) uses constant voltage.

What is a typical open circuit voltage for an arc welding machine?

The typical open circuit voltage for an arc welding machine is 50 volts to 80 volts. This is required for easy welding arc initiation.

Reference: Open-circuit voltage – Wikipedia