There are many types of welding machines available on the market today. Each type of machine has its own unique capabilities and features. Here is a look at some of the most popular types of welding machines in this post.

When it comes to welding machines, there is a lot of variation in terms of both price and features. This post will help you understand the different types of welding machines on the market and what their key features are.

What is a welding power source or welder?

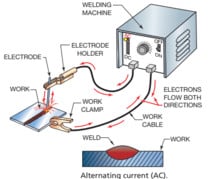

All arc-welding processes need a nonstop supply of electrical current in adequate quantity (amperage) and of correct voltage to sustain a welding arc.

This current may be either alternating (AC) or direct (DC), but it must be provided to the welding electrode by using a device that enables its precise control.

Only when the welding current is cautiously controlled, we can have the best welding arc characteristics and thus maximum welding efficiency – be obtained. This controlling device is called a Welding Power Source or Welder or Welding Machine.

Welding machines are an important tool for any welder. They are used to create the welds that hold together the pieces of metal being worked on.

There are many different types of welding machines, each with its own set of strengths and weaknesses. Some welders prefer one type of machine over another, but there is no one perfect welding machine.

It is important to choose the right machine for the job at hand, and to understand how it works so that you can get the best results from it.

5 Best Welders

Welding machines are an important tool for any welder. There are a lot of different welding machines on the market, so it can be hard to know which one is the best for you. In this article, we will discuss the best welding machines on the market and what makes them so great.

The first welding machine on our list is the Hobart Stickmate 160i Welder. This machine is perfect for light & medium duty projects. It is easy to use and has a lot of great features, such as an arc force adjustment knob and a thermal overload protection system.

Read more: Tips for buying a Welding Machine for home use

The second welding machine on our list is the YESWELDER ARC-145DS Welder. This machine is perfect for light & medium-duty projects. It has a lot of great features, such as dual operation i.e. it can be used for Stick welding & TIG welding.

A quick comparison of the best available Welders is listed below. You can easily buy these welders online. Check out these different Types of Welding machines.

| Image | Product | Details |

|---|---|---|

| Hobart Stickmate 160i | Reliable & Rugged Quality Portable (only 15 pounds) DCEP & DCEP Polarity 120V/240V input power. |

| YESWELDER ARC-145DS | Cheapest Welder for Stick & TIG Lift arc 110/220V Dual Voltage IGBT Inverter Hot Start |

| PRIMEWELD TIG225X | AC DC Tig/Stick Welder with Pulse Function 3 Year Warranty Best for Welding thin sheet, aluminum & stainless Steel |

| Lincoln Electric Stick Welder (AC-225) | AC/DC Stick Welder, 240 Volts Input, Ideal for Welding Rig |

| ESAB MINIARC Rogue ES 180i | Hi-Lo Welding Gauge Gage Both Inch and Metric Stainless Steel body |

Type of polarity and Welding process

The following are helpful tips to select the proper welder (power source) based on the type of welding current:

DC Welder (DCEP Power source) are used with the following welding process & Stick welding electrodes classification:

1. GMAW (Gas metal arc welding) also called MIG-MAG Welding

2. FCAW (Flux-cored arc welding) either FCAW-G or FCAW-S

3. Exx60 type electrodes e.g. E6010, E7010

4. Exx15, EXX18 type electrodes e.g. E7015, E8015, E7018

DC Welder (DCEP Power source) are preferred for:

1. Fast freeze applications

2. Fast follow applications

3. Welding stainless steel

4. Nonferrous electrodes

5. Surfacing with high alloy electrodes

AC Welder (AC Power Source)preferred for:

1. Fast-fill applications

2. Iron powder electrodes except out of

3. position welding

4. Where arc blow is a problem 5. Aluminum Welding

Alternating Current or Direct Current depending on the application is used with:

1. GTAW (Gas tungsten arc welding) also called TIG Welding

2. SAW (Submerged arc welding).

Types of Welding Machines or Welder

Different types of welding machines are used in industries. These machines provide welding current & voltage for a broader range to suit various welding needs.

The currents supplied through the power source may range from less than 10 amperes to 1500 amperes & voltage from 10 volts to 40 volts, or more, for example, a higher current for automatic welding.

Based on power type, polarity types, and functions, the Welding Power source or welder (4 types of welding machines) are classified into:

- Welding Transformer

- Welding thyristor

- Welding Rectifier

- Welding Converter

- DC Generator

- Switched-mode power supplies

Now, all the welding machines no matter which welding process are based on these above 4 types.

Further, based on the welding process the main types of welding machines used for welding operations in industries are:

- Stick Welding or SMAW Welding Machine

- Gas welding Machine

- TIG Welding Machine

- MIG-MAG or FCAW Welding Machine

- SAW Welding Machine

- Plasma arc Welding Machine

- Laser Welding machine

- Resistance Welding Machine

- Stud Welding Machine

- Plastic Welding Machine

- Friction Welding Machine

- Projection Welding Machine

- Electron Beam Welding Machine

- Electroslag welding Machine

- Seam Welding Machine

- Flash Welding Machine

- Ultrasonic welding Machine

- Spot Welding Machine

Types of Welding Machines or Welders based on Electrical/ Electronic Characteristics

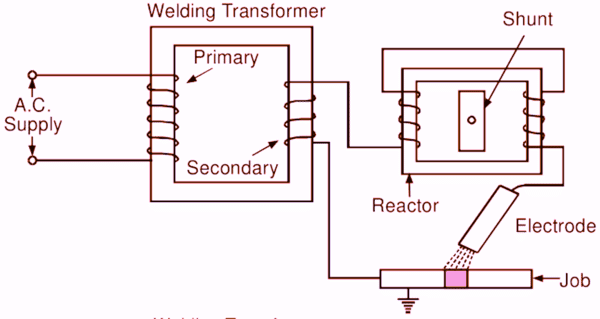

Transformer Welder (AC Transformer Power Source)

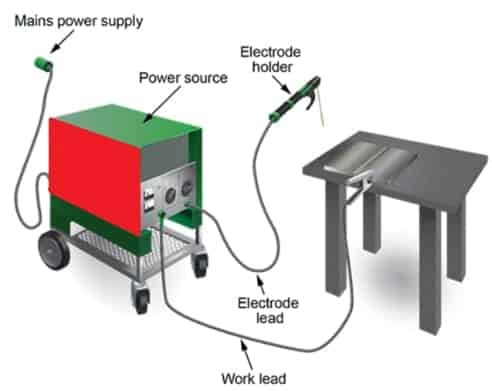

A transformer welder is a voltage step-down transformer that changes high voltage, low-amperage AC input current to low voltage, high-amperage AC welding current.

Transformer welders generally run on single-phase power. Most AC power made in the United States is 60 hertz, and each time the polarity changes the voltage goes through zero, which tends to create an unstable condition in the arc.

This problem, however, has been solved by designing better brief characteristics in the welder and better AC electrodes. An example of a welding transformer is shown in the below figure.

Transformer-Rectifier Welders

In a welding machine, the Rectifier converts input AC to output DC so it can have negative and positive polarity.

A single-phase rectifier welder is a transformer welder with a rectifier added to obtain a DC output. The output characteristic can be either constant or variable voltage.

Welders or welding machines built using rectifier technology for MIG-MAG welding have controls for adjusting the current, voltage, and polarity for good welding performance.

Rectifier Welder

Rectifier welder is the step-down transformer, in which three-phase AC is fed to rectifier units which, in turn, feed DC to a single output circuit.

The output in a welding rectifier is always direct current (DC). This can be either constant or variable DC.

Rectifier uses either a diode or thyristor or transistors for converting the AC to DC for welding output.

Direct current (DC) offers to use welding polarity for welding operations either DCEP (Direct current electrode positive) or DCEN (Direct current electrode negative). A choking device at the end allows current and voltage adjustment.

DC Generators

The DC motor-generator welder is driven by AC utility power. DC Generators are useful for field welding applications such as welding of cross-country pipelines or in mines.

They provide both constant and variable DC for welding. The DC generator motor is generally a three-phase induction motor. Usually, gasoline is required to run the DC generator.

Welding Analog Power Supply

Analog power supplies are the latest technology in welding power sources by using dedicated and sophisticated electronic circuits.

This allows very fine-tuning of welding parameters such as current, voltage, arc length, type of current, pulse current output, and storing the welding programs in the welder database. These machines also offer a synergic welding supply.

A single welder (welding machine) can be used for AC, DCEP & DCEN along with pulse welding parameters controls, thus allowing good welds.

Although, the cost of such machines is very high compared to others such as welding transformers or welding rectifiers.

These are all the main types of welding machines used in welding industries, home uses and site works. Before making a purchase, make sure to read our tips for buying a welding machine.

How Welding Machine Works?

A welding machine is a device that uses electrical current to create heat, which melts metal and allows it to be joined together. Understanding how this process works can help you select the best welding machine for your needs.

A welding machine consists of three main components: the power supply, an electrode holder, and cables that connect the power supply to the electrode holder and workpiece.

An input AC supply (High voltage and low current) is supplied to the welding machine which is converted to low voltage and high current using a transformer in the welder.

The output is low voltage to make it safe while a high current is useful to provide high heat input to melt the filler wire.

The power source provides electricity to heat up the materials being welded, while the electrode holder holds an electrode connected to one side of the power source. The cables allow for electricity to flow between all three components. When current passes through the electrodes, it produces an arc that melts both materials being welded together at their surfaces.

The most common type of welding machine uses Direct Current (DC) power from a generator or mains electricity supply to produce an electric arc between the electrode and workpiece.

This arc produces intense heat, up to 6500 degrees Celsius, which melts metal at the joint. The molten metals are then allowed to cool and form a strong bond between them.

Different types of welding machines exist for different materials and applications; some use alternating current (AC) instead of direct current (DC) as explained earlier in this article.

Types of Welding Machines based on Automation

Welding is an essential skill used in a variety of industries, from automotive repair to construction. Welding machines are a key component of the welding process, and there are several types available based on automation capabilities.

The most commonly used welding machines include

- Manual welders (Stick Welding & TIG Welding),

- Semi-automatic welders (MIG welders),

- Automatic welders (SAW Welders), and

- robotic welders (Robotic MIG).

The most basic type of welding machine is a manual welder which requires the user to manually operate the equipment for performing welding tasks.

- Manual welders can be used for a variety of applications and provide high-quality results when operated properly.

- On the other hand, semi-automatic welders use some level of automation to reduce operator fatigue, improve accuracy and provide faster throughput rates than manual welders.

- Semi-automatic welders automate some parts of the welding process but still require an operator to control certain aspects, such as selecting the proper settings or guiding the torch along the desired path.

- Automatic welders are designed for specific applications and do not require any human intervention; they are completely automated and use sensors to adjust parameters based on their environment.

Welding Systems

Welding systems are an essential component of any fabrication process. From large-scale industrial applications to small repair jobs, welding is a powerful technique used to join two or more metal parts together in a permanent fashion.

A welding system consists of the following components: welders, power sources, control units, and consumables.

With so many types of welding machine systems available on the market today, it can be difficult to select the right one for your needs. Newer welding machines are also more energy efficient than traditional models, allowing operators to complete tasks without wasting resources.

Different welders provide different levels of power output, duty cycles and other features that can affect the efficiency and quality of your welds. To find a welding system that best suits your project requirements you should take into consideration factors like budget, portability, safety features and the type of material being joined.