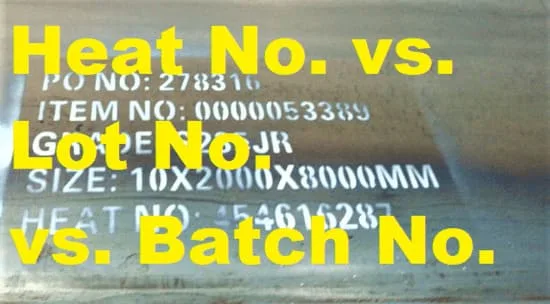

When purchasing steel products (E.g., Plate, Pipe, Bar), the steel manufacturer must deliver the material certificate, known as Mill Test Certificate (MTC), to the buyer.

This MTC includes all the specifications of steel products, including weight, dimensions, chemical composition, mechanical properties, heat treatment status, test values, heat traceability, etc.

This information declares that the quality of steel products has been reliably satisfied. The inspection document and certification were earlier specified in the German standard DIN 50049.

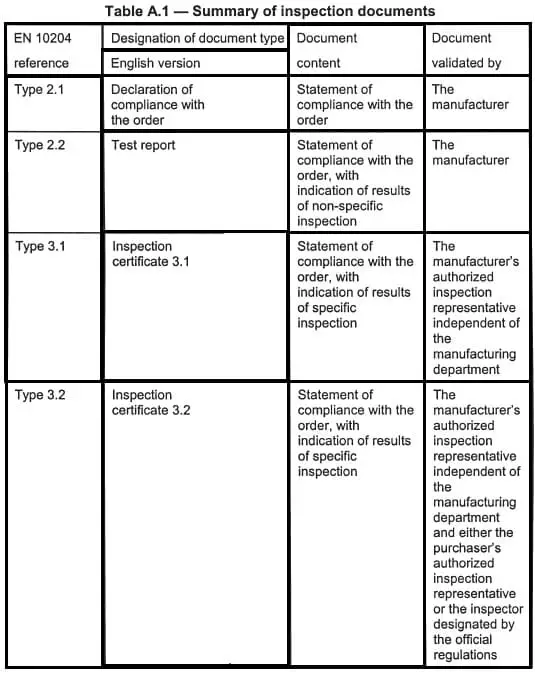

The definition of material testing and certificate type in DIN 50049 was adopted in 1991 as the European standard EN 10204, which led to the classification definition of certificate types 2.1, 2.2, 2.3, 3.1A, 3.1B, 3.1C, and 3.2 while following the definition of the German standard DIN 50049.

What is a material certificate?

A Material Certificate, or MTC, is a document that certifies the chemical, mechanical and physical properties of a material. It is also known as a Mill Certificate or TEST CERTIFICATE.

The MTC is an important document for manufacturers and suppliers, as it guarantees the quality of the material.

The certificate includes the material’s chemistry and heat treatment, as well as its physical properties such as density, strength, and hardness.

BS EN 10204 or DIN EN 10204 is a European standard that describes the types of Inspection documentation requirements for the supply of metallic products.

It can be used for non-metallic products also as agreed during ordering. In EN10204, the following certification types are given:

- Type 2.1

- Type 2.2

- Type 2.3 (incorporated in Type 3.1 certificate)

- Type 3.1

- Type 3.2

Changes in EN10204 Material Inspection Document

Finally, EN 10204 was revised again in October 2004 and issued as BS EN 10204:2004. EN10204:2004 further simplified inspection documents (certificate types) into four categories under the title “Metallic Products—Types of Inspection Documents”, leaving only 2.1, 2.2, 3.1, and 3.2 at this time.

| EN 10204:1991 | EN10204:2004 |

| Certificate type 2.3 | deleted |

| Certificate type 3.1B | Changes to Certificate type 3.1 |

| Certificate type 3.1A, 3.1B, 3.2 | Consolidate changes to Certificate type 3.2 |

What is the Difference Between 2.2 and 3.1 Material Certificates?

A 2.2 Test Certificate is a Test Report as a compliance statement based on previous test results data & the actual material is not tested.

The manufacturer certifies that the material supplied under a Type 2.2 certificate will meet the requirements. Type 2.2 certificate is validated by the manufacturer.

On the other hand, a 3.1 certificate supply the material with actual test results. The product manufacturer certifies the test certificate and declares that the product shall meet the material standards requirements.

Type 3.1 certification is an Inspection Certificate validated by the manufacturer-authorized inspector (Inspector is independent from manufacturing department).

A summary of inspection documents as per EN10204 for Type 2.1, Type 2.2, Type 3.1 & Type 3.2 are given in the below table.

Difference Between 3.1 and 3.2 Material Certification?

Both 3.1 & 3.2 certificates are inspection certificates providing the compliance of the product supplied with actual material test results.

Type 3.1 Inspection Certificate is the actual test value of a material in a lot of steel products supplied.

Type 3.2 Inspection Certificate is similar to Type 3.1 but additionally will be signed and verified by an independent inspector from a third party that approves the material.

A 3.2 certificate is validated by the manufacturer-authorized, inspection personnel e.g., QC Engineer and there is no role of the manufacturing/ production department in the certificate authority. The inspector can be purchased authorized inspector or an inspector from the regulatory body.

This above personnel declares that the product is in compliance with the minimum specified requirements of the material standard. The product under 3.2 certification has been tested under quality requirements.

On the other hand, a 3.1 certificate supply the material with actual test results. The product manufacturer certifies the test certificate and declares that the product shall meet the material standards requirements.

Type 3.1 certification is an Inspection Certificate validated by the manufacturer-authorized inspector (the Inspector is independent of the manufacturing department).

Difference Between 2.1 and 2.2 Certification?

A type 2.1 material certificate is a certificate of compliance (Known as COC) or simply a declaration of compliance.

A type 2.1 certificate is a document certified/validated by the manufacturer that it shall meet the requirements without any actual test. There is no mention of test results on the test certificate.

A Type 2.2 certificate is a test report. It is a document in which the manufacturer certified that the product supplied complies with the requirements of the purchase order.

The result of the non-specific test is provided in the test report instead of the actual material results.

Difference Between 2.1 and 3.1 Certification?

A 3.1 material certificate is a document that verifies the chemical and physical properties of a material.

The certificate is issued by an accredited testing laboratory and includes information on the material’s composition, mechanical properties, and thermal properties.

A 3.1 material certificate is essential for ensuring that materials meet safety and performance requirements.

A type 2.1 material certificate is a certificate of compliance (Known as COC).

A type 2.1 certificate is a document certified by the manufacturer that it shall meet the requirements without any actual test. There is no mention of test results on the test certificate.

What is a 3.1 Material Certificate?

A 3.1 material certificate is a document that verifies the chemical and physical properties of a material.

The certificate is issued by an accredited testing laboratory and includes information on the material’s composition, mechanical properties, and thermal properties. A 3.1 material certificate is essential for ensuring that materials meet safety and performance requirements.

A 3.1 Certificate ensures the material supplied is tested to confirm the minimum requirements. The test is carried out on the same material that is supplied to the purchaser.

There are two types of Type 3.1 certification based on the issuing authority level:

- Type 3.1

- Type 3.2

What is a 3.2 Material Certificate?

In a type 3.2 certificate, both an inspector, independent of the manufacturer certification department, appointed by the manufacturer and also an inspector appointed by the purchaser or an inspector named in the official regulations, confirms that the supplied products meet the requirements specified in the purchase order, including the test results details.

A 3.2 material certificate is a document that verifies the chemical and physical properties of a specific material.

This certificate is often used by manufacturers and suppliers to ensure that the materials they are using meet specific industry standards.

The 3.2 designation refers to the fact that the document has been created in accordance with European standard EN 10204.

What is a 2.1 Material Certificate?

A type 2.1 material certificate is a certificate of compliance (Known as COC).

A type 2.1 certificate is a document certified by the manufacturer that it shall meet the requirements without any actual test. There is no mention of test results on the test certificate.

So, the manufacturer takes the responsibility that the material is having the minimum required mechanical & chemical properties, for example, but there is no actual test conducted on the supplied material.

What is a 2.2 Material Certificate?

When the manufacturer certifies that the respective products meet the requirements specified by the purchaser in the order, he issues certificates of compliance containing test results based on other inspections and tests.

A Type 2.2 certificate is a test report. It is a document in which the manufacturer certified that the product supplied complies with the requirements of the purchase order.

The result of the non-specific tests are provided in the test report instead of the actual material results.

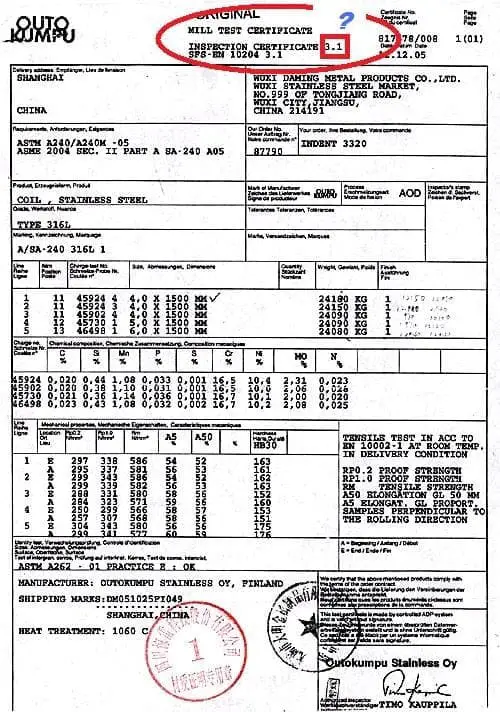

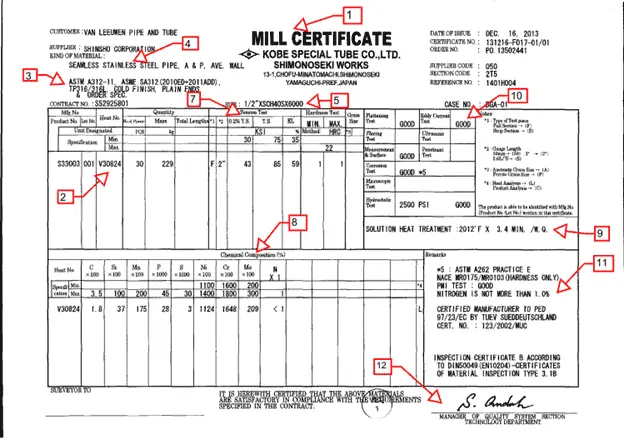

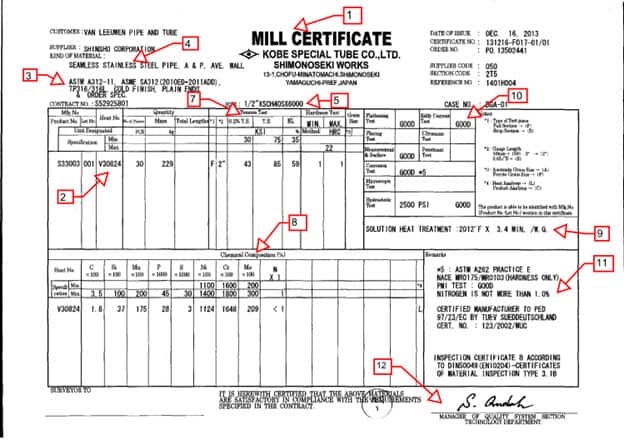

EN 10204 type 3.1 certificate example

An EN 10204 type 3.1 certificate is a document that is used to certify the quality of a product.

This type of certificate is usually issued by the manufacturer and it indicates that the product has been manufactured according to certain standards.

The certificate also provides information about the product, such as its dimensions and weight.

An EN 10204 type 3.1 certificate can be used to demonstrate the quality of a product to potential buyers or suppliers. An example certificate for 3.1 certifications is given below.