What is Fracture?

A fracture is a material split that encompasses the entire cross-section of a material, component, or complex technical system, causing it to fall apart with irregular surfaces. In many cases, fractures can start as cracks.

Where crack refers to a material split that does not encompass the entire cross-section of a material, component, or complex technical system, not yet causing it to fall apart. Cracks are in many cases starting points of a fracture.

The cause of numerous cases of damage, such as the sudden breaking of a series of “Liberty ships” and “T2 tankers” in the 1940s, or the numerous spectacular crashes of the DeHavilland DH 106 “COMET”, the world’s first production jet engine airliner, in the 1950s were finally explained by evaluating the fracture mechanisms.

Types of Fractures

All fracture types involve combinations of the parameters listed in this summary and depend on the type of stress, type of deformation, and type of fracture mechanism operating in the relevant material.

The main types of fracture mechanisms observed in engineering materials are shown below:

- Forced fracture

- Fatigue related fracture

- Ductile fracture (ductile failure)

- Brittle fracture (cleavage fracture)

- Sliding fracture

- Cleavage fracture fracture

What is Forced Fracture?

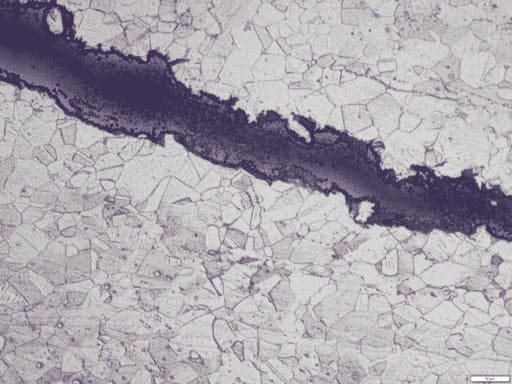

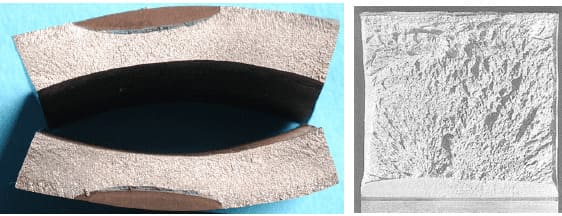

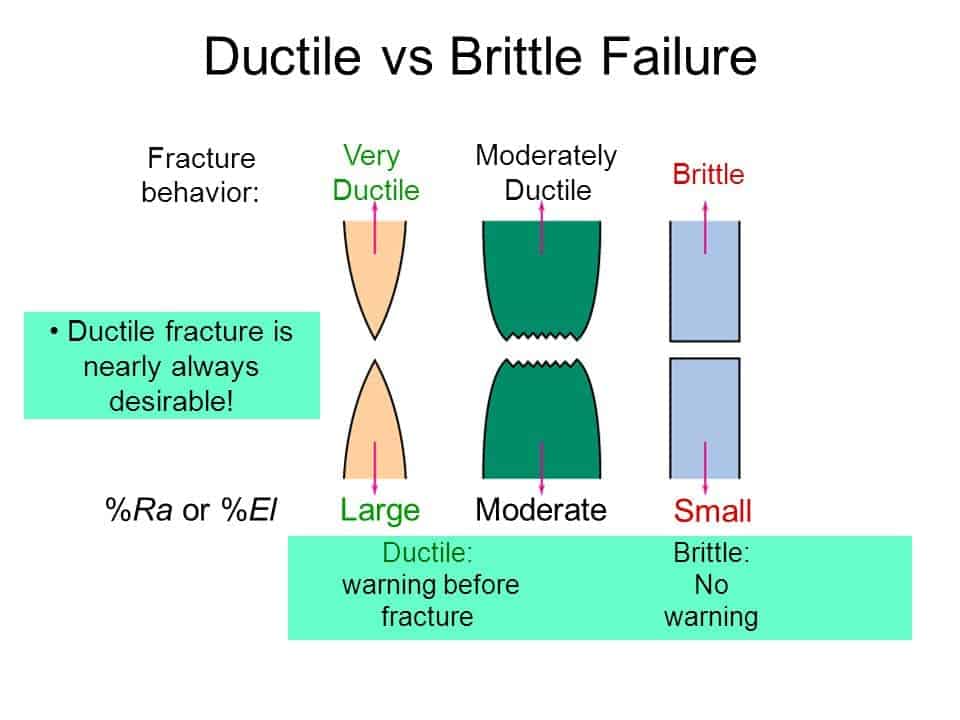

Forced fractures are the types of fractures where external stresses make a material break. Forced fractures can be divided into brittle fractures and ductile fractures. As is evident in the below picture, brittle material characteristics result in brittle destruction.

This can occur in both transgranular and intergranular. On the other hand, ductile fractures are characterized by a more or less distinct reduction of area.

The fracture can begin as an internal honeycomb formation but, with sufficient flowability, this is not necessarily the case.

What is Ductile Fracture?

The flow of a material can be seen as the sliding of the crystal planes across one another and therefore the movement of dislocations.

The material behaves plastically and is therefore ductile. The crack starts with the confluence of dislocations (linear lattice faults) at grain and phase boundaries.

As a result, local stress concentrations are developed. Finally, in this way the fracture is linked to high local deformations.

What is Fatigue Fracture?

Fatigue or cyclic fractures are formed if, due to applied load changes, micro-plastic processes take place at the smallest internal or external surface notches.

These can lead to stress peaks on a microscopic or macroscopic level.

Consequently, yield strength and elongation excesses lead to small or microscopic cracks in the microstructure. The formation of these cracks depends on many parameters.

These include:

– the intensity of the load,

– the duration of the load,

– the type of load,

– the form of the notch,

– the size of the notch.

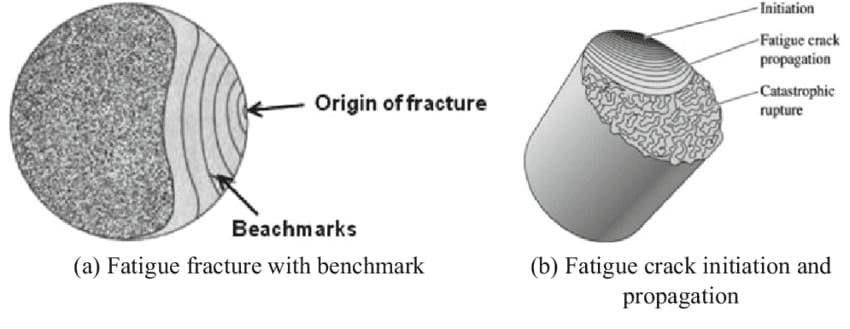

The result is a crack with wedge-shaped sections. In addition, fatigue fractures feature a smooth, brittle main fracture surface with numerous “lines of rest” as well as a rugged, coarse residual forced fracture which can occur both ductile and brittle.

Fatigue Fracture appearance

The fatigue fracture is characterized by a deformation-poor, flat, brittle surface. On this surface, lines of rest are often recognizable which describe the stopping and the crack propagation.

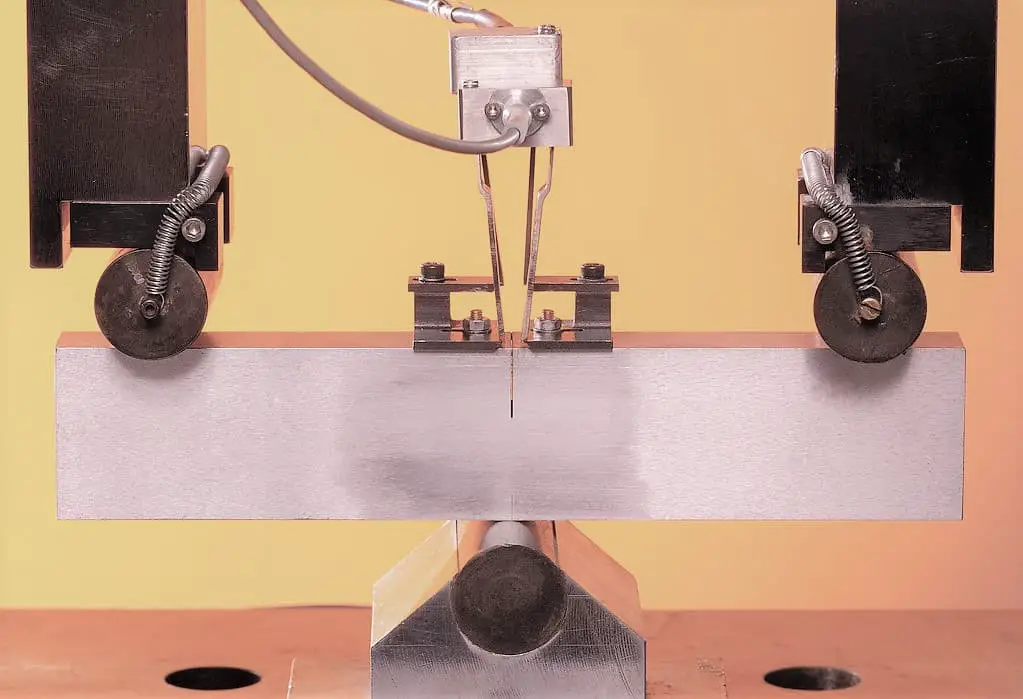

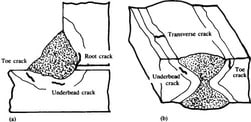

The position of the first initial crack is at the notch base of a surface notch (root-notch, transition surface-notch weld metal -base metal, an imperfection in the weld, etc.) containing high-stress concentrations.

The surface of the residual fracture depends on the ductility of the material. In ductile materials, this particular surface resembles the residual fracture area of a ductile fracture where plastic deformations can be recognized.

In the case of brittle materials, the residual fracture is also brittle.

Factors affecting fatigue strength of a material

The following factors affect the fatigue strength of material:

- The maximum stress

- the minimum stress

- the mean stress

- the stress amplitude

- the number of cycles

- the stress ratio and

- the stress collective.

These are mainly parameters that are easy to record. Beyond this fatigue strength is determined by yet a variety of other parameters. These are among others:

- the material,

- the structural-related stress concentrations

- the surface quality,

- the stress concentration due to surface notches,

- the weld quality,

- the type of load,

- the direction of load,

- the presence of residual stresses,

- the scale effect,

- corrosion and

- temperature.

What is Creep Fracture?

What is Creep failure and stages of creep?

At constant stress and above a so-called transition temperature Tt or Tü, transgranular (e.g. due to dislocation movements/ vacancy diffusion) and intergranular (e.g. grain boundary-slide/ diffusion) processes take place in the microstructure.

This is firstly associated with a linear increase followed by an exponential increase in strain. This phenomenon is referred to as creeping.

However, sooner or later the material will no longer be able to compensate for the constant increasing strain and cracks that occur that form the start of fractures, known as creep fractures.