What is Nick Break Test

A nick break test, also known as a fracture test, is a welding quality assurance test used to determine the soundness of a weld. The test involves taking a small sample of the weld and breaking it apart to check for any cracks or other defects.

Nick Break Test is applied to a welded butt joint in a plate or pipe to check weld soundness. The typical specimen dimensions for plate and pipe. It is not necessary to remove the weld reinforcement.

How do you perform a nick break test?

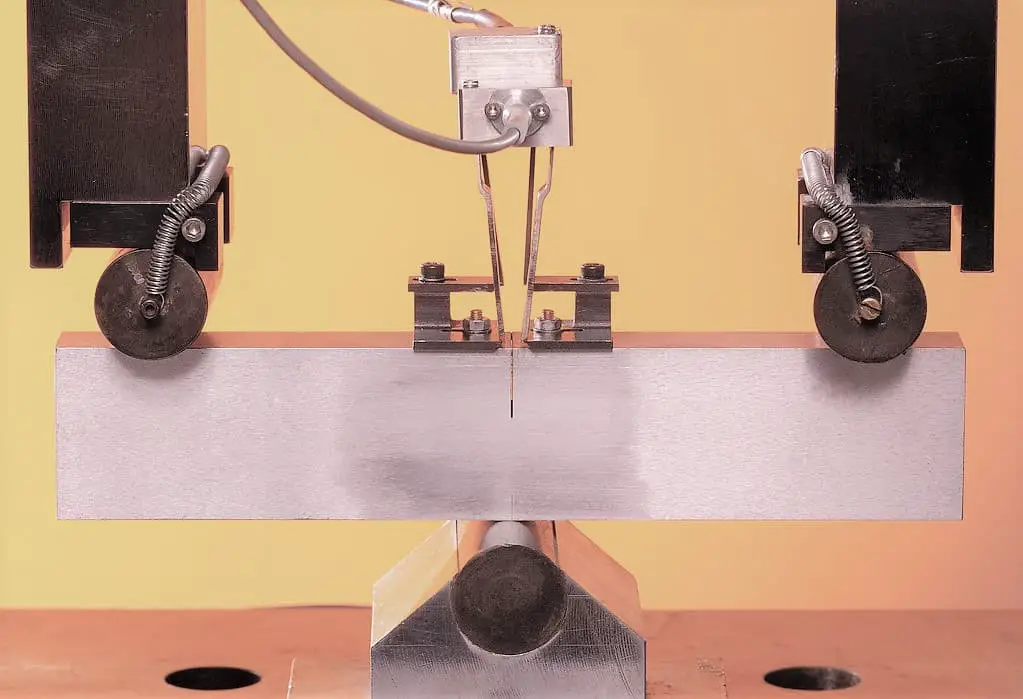

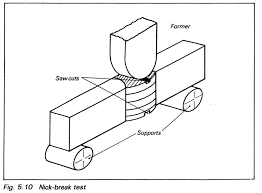

The sample is braced as shown in the Below figure and ruptured by giving one or more sudden heavy blows with a hammer at the point of the nick or the notch as indicated.

Force to break the specimen in Nick break test can be applied by:

- Pulling

- Striking with a hammer

- Bending

The rate of applying the force is not critical, because it has no effect on the appearance of the fractured surface.

Related Reading: Weld Testing Methods & Welding Test Types

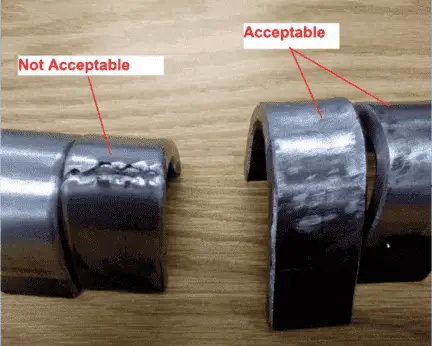

Nick Break Test Defects

The surface of the fracture is examined for the presence of internal defects, such as lack of fusion, slag inclusions, and porosity. Fisheyes during examination of nick break test is not a reason for rejection as allowed in API 1104.

This test can be conveniently carried out in shops and at Sites for quick assessment of weld quality, since no elaborate equipment is necessary, and the interpretation is relatively simple.

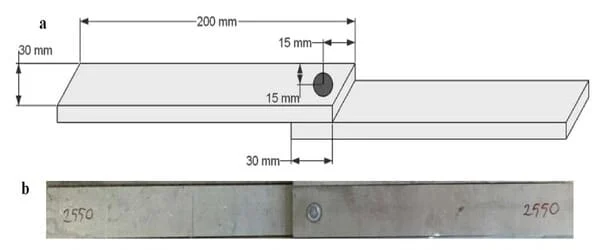

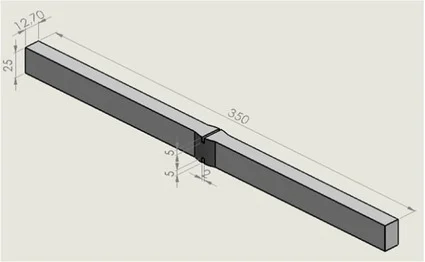

Nick Break Test Specimen

Nick break test specimen are similar to bend test specimens. The only difference is the presence of artificial notch prepared by grinding on the nick break test specimen.

As per API 1104, nick break test specimen dimensions are:

- Length: Approximate 9 inch (230 mm)

- Width: 1 inch (25 mm)

- Depth of notch: 1/8 inch (3 mm)

The specimen can be cut by machining or gas cutting.

Nick break test specimen can have notch in three possible ways as:

- Side Notch (most commonly used)

- Face Notch

- Root notch

Similar to bend test, Nick break test or Fracture test can be carried out to break the specimen from side, face or root side to reveal the internal welding defects.

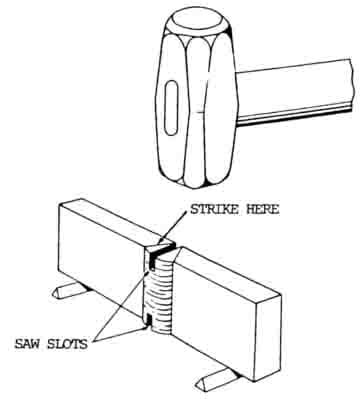

Fracture Test (Nick Break test) in Workshop

You can perform the fracture test in welding shop with minimal efforts. The test is performed by holding the specimen in a vice and then blowing with a hammer on the transverse side to make it fracture.

Nick Break Test Code

Nick break test is defined in API 1104 standard. In API 1104, Clause 5.6.3, Nick break test is defined. This clause covers sample preparation, Nick break test method, and test requirements.