Welding Bend Tester

Welding Bend Tester is a device that is used to measure the quality of welds. This quality verification is usually required either for:

- Welder Performance Testing– Welder Test

- Procedure Qualification Testing– PQR Test

It is also used to measure the degree of bend that a weld can withstand. The Welding Bend Tester is made up of two clamps. One clamp is fixed and the other clamp moves. The weld is placed between the two clamps and the amount of bend is measured.

Why does Welder Use Weld Bend Tester?

Welders use a welding bend tester to check the welds they make for soundness and to identify any flaws. A welding bend tester is a simple tool that consists of a metal plate with a hole in the center and two clamps. The welder places the welded piece in the test jig, pulls it tight between the clamps, and then bends it. By watching how the weld bends, the welder can tell if it is strong enough.

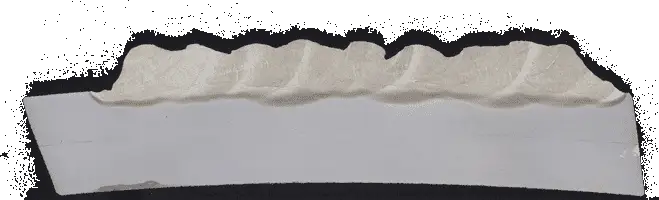

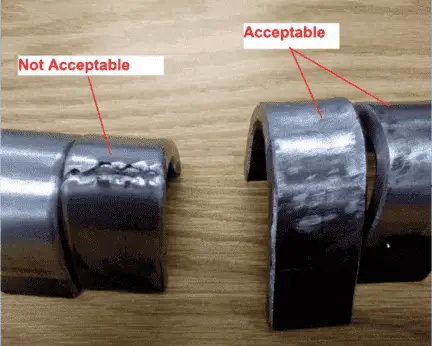

The welder needs to pass the bend test to get a certified welder tag. The test specimens are cut from the welder test coupon and tested on a bend tester. During bending, if any internal weld imperfection or welding defect is present, it gets elongated and breakout to the specimen surface as shown in the below picture.

Bend Tester For Welding

Welding bend testers are an essential tool for welding professionals. They are used to test the weld’s ductility and its ability to resist bending. This is important because it helps ensure that the weld is strong enough to withstand stress and strain. There are a variety of welding bend testers on the market, so it is important to choose one that is suited for your needs.

The most common type of welding bend tester is the universal type. This type can be used to test both butt joints and fillet welds. It has two arms that are adjustable, so it can be used for different-sized welds. The arms are also equipped with clamps so that the specimen can be securely held in place during testing.

Another type of welding bend tester is the plate-type tester. This type is designed specifically for testing plate welds.

Homemade Weld Test Bender

Welders are always looking for ways to make their lives easier, and one way to do that is by having a homemade weld test bender. The weld test bender is a simple way to improve the quality of your welds, and it’s easy to make your own.

A homemade weld test bender is a simple piece of equipment that can be made using a hydraulic cylinder and a mandrel. The hydraulic cylinder is used to push the mandrel through the material to be bent, and the amount of force required to do this can be used to measure the ductility of the material. This type of bender is quick and easy to use, and it can be modified to suit specific needs.