What is Brittle Fracture?

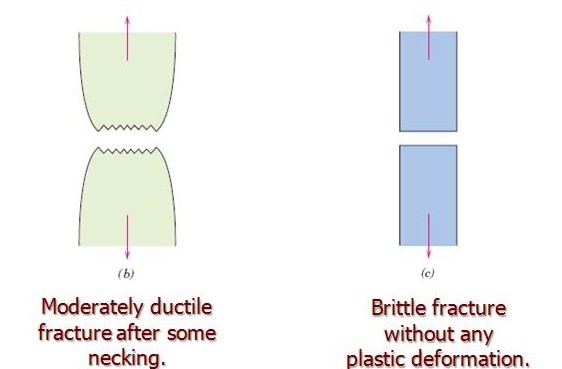

The term ductile and brittle is used to distinguish failures of materials characteristics by high and low toughness respectively.

Brittle Fracture is the sudden & very fast cracking of material or equipment under stress. A brittle fracture occurs without any plastic deformation (No thinning or necking) or little deformation only by direct separation along crystallographic planes due to a simple breaking of atomic bonds.

In brittle fracture, materials show no warning before failure, hence brittle fracture can be catastrophic in nature. After failure material broke into many pieces with little to no deformation in shape.

The surface appearance of brittle fracture is relatively smooth and is often shiny in appearance. Although not all brittle fracture is perfectly smooth some brittle fracture demonstrates Chevron markings appear in the fracture area.

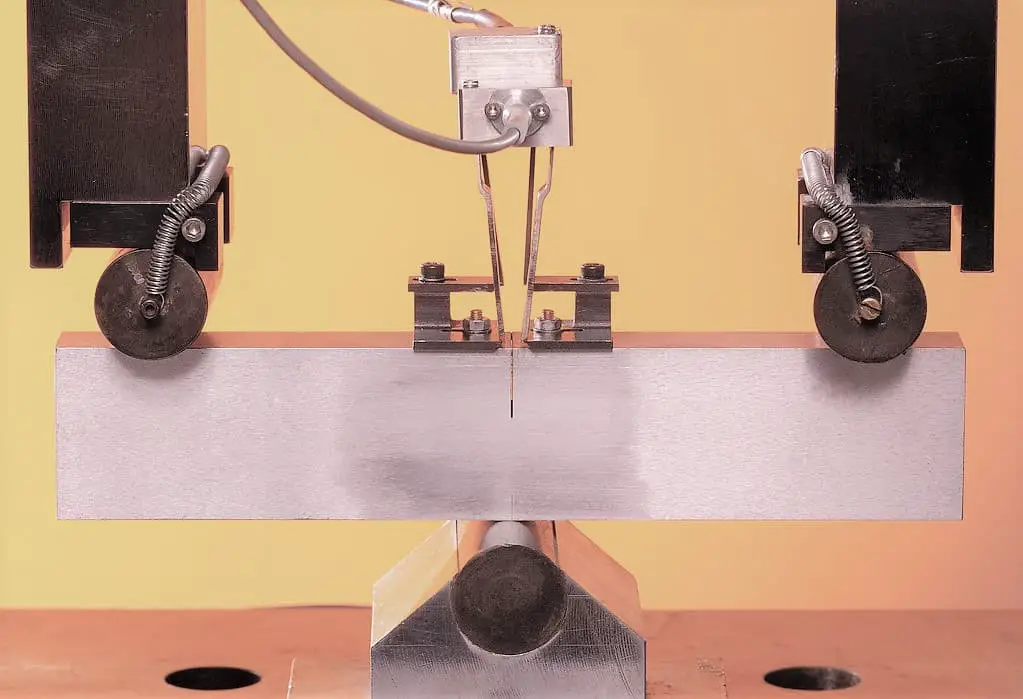

In a Charpy Impact test, brittle metal will absorb a small amount of energy when impact tested, while a tough ductile metal absorbs a large amount of energy. Pure brittle fracture is called cleavage fracture.

Mechanism of Brittle Fracture

Brittle fracture is usually due to low temperatures in ferritic & martensitic materials whereas austenitic materials exhibit ductile behavior even at low temperatures.

If the material temperature or let’s assume Steel is at or below its brittle-to-ductile transition temperature, then it will be highly susceptible to brittle fracture.

This situation can be aggregated by the presence of defects (e.g. notch or crack) and high stress on this defect (either applied or residual), -which will most likely result in brittle fracture.

Factors affecting Brittle Fracture in a material

Below are the factors that can increase the susceptibility to brittle fracture:

Metallurgical Degradation

Materials properties degradation (Temper embrittlement, sigma phase embrittlement, graphitization, and 885°F or 475°C embrittlement) resulted due to elevated temperature applications. These failure mechanisms if present will aid in material failure by brittle fracture.

Material Cleanliness and Grain Structure

In the case of steel, material toughness can be decreased due to large grain sizes and steel contaminants, thus making the material more brittle.

The addition of alloying elements which can affect its microstructural properties are can also make the material brittle. For metals, the microstructure grain size is a strong determinant of notch toughness.

The grain size has a profound effect on the yield stress and strain hardening rate and it is, hence, logical to expect grain size to influence fracture toughness.

Microstructure with fine grains possesses high mechanical properties while coarse grain microstructure is prone to brittle fracture. Example- Cast iron having coarse grain is highly brittle while a forging with fine grain offers high mechanical properties.

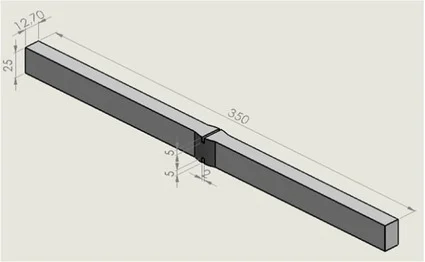

High Material Thickness

Both geometry of cross-section and its size can influence the nominal strength of a material. Actually most of the materials show a marked size effect, for example, large sections are more prone to brittle fracture.

The determination in the strength of thick sections has been attributed to the increased amount of impurities, flaws, and discontinuities present in thick sections.

Thick materials are more prone to brittle failure due to the high tri-axial force working on them. Thick plate thickness has high restraint and can absorb more residual stresses without showing any significant deformation.

High residual stresses

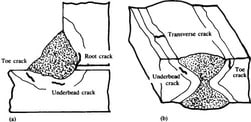

The heating and cooling cycles of welding result in the development of residual stresses. The stress level in a welding joint could be large enough to reach the yield point of the material and may lead to brittle fracture in the presence of any crack.

The combination of welding residual stresses and material strain aging is considered to be a known cause of brittle fracture.

Brittle fracture is more likely in the presence of high residual stresses or if the structure is highly loaded, particularly under a high strain rate (impact loading).

Stress concentrations (from weld toes, change of section, notches) and weld defects (such as cracks or lack-of-fusion) can have a major effect on the likelihood of brittle fracture. Susceptibility of brittle fracture could be induced by a triaxial stress state like imposition of a high strain rate.

Low temperature

The ductile to brittle transition in steels at low-temperature influences whether a failure will be ductile or brittle. At low temperatures, the material has lower fracture toughness and is more prone to brittle fracture.

Low toughness is more likely in materials with a crystalline structure which is body-centered cubic (bcc) ferritic steels because they show the toughness transition, compared with those with face-centered cubic (FCC) crystal structures, such as austenitic stainless steel or aluminum which do not show a marked transition between ductile and brittle behavior.

Low toughness can result from the steel’s microstructure as a fine grain size has high toughness whereas martensite or coarse grain HAZ have low toughness.

Material thickness also has an effect on the fracture toughness with thick material having lower effective toughness than thinner plate made from the same material.

Brittle fracture surface appearance

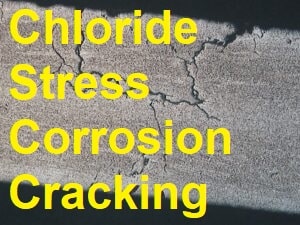

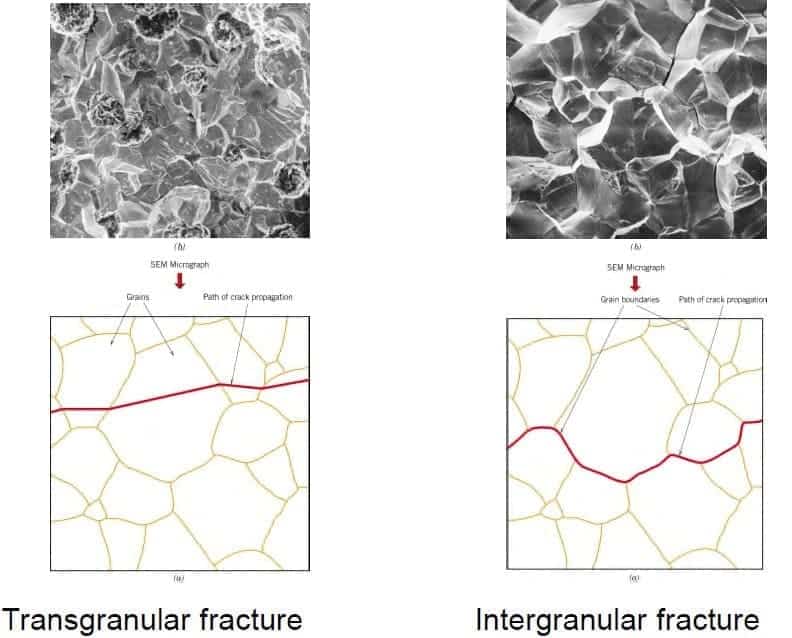

Brittle fracture can appear intergranular (between grains) and transgranular (within grains).

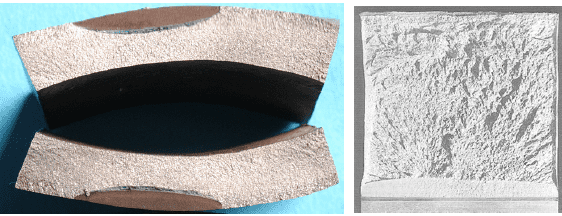

The characteristic of brittle fracture is that there is little or no plastic deformation (necking or thinning) before failure.

The fracture surface can reveal chevron marks or river lines pointing back to the fracture starting point as stated earlier in this post.

In a brittle impact fracture, the fracture face is rough but not torn and will sometimes have a crystalline appearance (particularly under high strain rate loading, for example in a Charpy specimen).

The fracture surface of a brittle material will typically have a distinct appearance, characterized by a lack of plastic deformation and a smooth, glassy surface. Some common features of a brittle fracture surface include:

- Flat, smooth surface: The fracture surface is often smooth and flat, with minimal signs of plastic deformation.

- Lack of deformation: Unlike ductile materials, brittle materials do not undergo significant deformation before breaking. As a result, the fracture surface will typically show little or no signs of deformation.

- Sharp edges: The edges of the fracture surface will often be sharp and well-defined, as there is little or no deformation around the edges.

- Lack of shear lips: Brittle materials typically do not exhibit shear lips, which are characteristic of ductile materials.

- Intergranular fractures: In the case of brittle materials, such as ceramics, often show intergranular fractures, which occur between the grains of the material.

- Cracking pattern: brittle materials tend to have a more complex cracking pattern, with multiple small cracks branching off from the main fracture.

- Transparent or translucent appearance: Brittle materials often have a glossy, transparent or translucent appearance when viewed under a microscope.

Types of Brittle fracture

There are two main types of brittle fractures in materials:

- Transgranular and

- Intergranular.

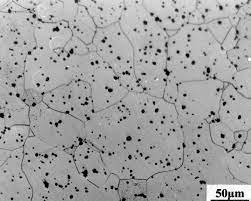

In transgranular fractures (within grains) as shown in the below picture- the fracture occurs through the material grains.

The path of fracture changes from one grain to another because it follows the least resistance during fracture.

Intergranular brittle fracture (Between grains)- appears along the grain boundaries as shown in the above picture. This type of fracture occurs due to weak & brittle grain boundaries.

This usually occurs when there has been a process to weaken the grain boundaries.

Intergranular or intercrystalline fracture involves pulling apart the individual crystals from their adjacent crystals. Such fractures are caused by the presence of impurities at the grain boundaries.

Prevention of brittle fracture shall be taken into consideration during the component design stage.

The operating temperature of the material must be at or above its brittle-to-ductile transition temperature during service and testing. Anticipated repairs of brittle materials must be considered and preventive measures shall be put in place before commencing the repairs.

brittle fracture vs ductile fracture

Brittle fracture of material refers to the type of failure mechanism where material shows little or no deformation and it’s a sudden failure without any warning.

Breaking of rock, glass, cast iron is an example of brittle fractures as they break without any deformation.

A ductile fracture means fracture of material with large plastic deformation (Thinning or necking) before fracture. Fracture of mild steel and other ductile metals such as copper, nickel, rubber, and plastics is an example of ductile fracture.

What is the difference between brittle and ductile fractures?

What materials are prone to brittle fractures?

What materials are prone to ductile fractures?

What are the characteristics of brittle fracture surfaces?

What are the characteristics of ductile fracture surfaces?

Why is it important to be able to distinguish between brittle and ductile fractures?

Brittle fractures can be caused by factors such as low temperature, high stress, and a lack of corrosion resistance, while ductile fractures can be caused by factors such as high temperature, low stress, and a lack of toughness.