885°F or 475°C Embrittlement

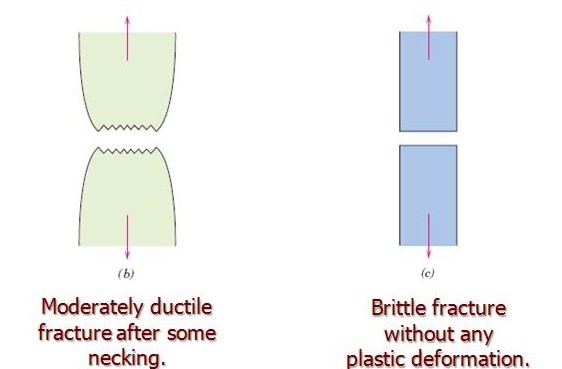

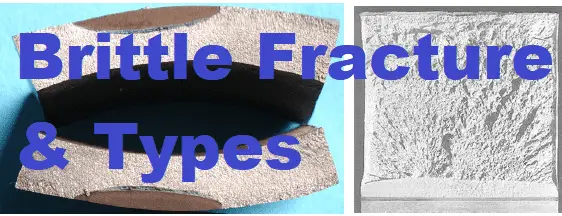

It is a loss of ductility and fracture toughness of the material, because of the metallurgical change, that can take place in stainless steels, containing a ferrite phase, as the result of the application of these materials in the temperature range of 600 °F to 1000 °F or 315 °C to 540 °C. This type of embrittlement can lead to cracking failure.

Watch this YouTube video for full classroom training on API 571 Damage Mechanism- 885°F or 475°C Embrittlement.

When the stainless steel material is subjected to a temperature of 400 – 550°C (maximum effect at 885°F), the material exhibits a rapid decrease in the material toughness after an increased time period. The reason behind this is the chromium-rich domains that form and precipitate at this temperature range within the Fe-rich matrix by ferrite perishing. Once the chromium content rises, the effects are more pronounced.

This phenomenon is termed 475°C or 885°F embrittlement as the rate of embrittlement is highest at 475°C/ 885°F. It is also called thermal aging embrittlement.

Which materials are being affected by the 885°F Embrittlement

400 series SS (for example 405, 409, 410, 410 S, 430, and 446).

Duplex stainless steel such as Alloys 2205, 2 304, and 2507.

Austenitic (300 series) stainless steel weld metals, which normally contain up to about 10 % ferrite phase to prevent hot cracking during welding.

Critical Factors for the 885°F Embrittlement

a. Alloy composition, particularly chromium content, amount of ferrite phase, and Operating temperature.

b. The lower-chromium alloys, (For example SS405, SS409, SS 410, and 410 S) are less susceptible to embrittlement. The higher chromium ferritic stainless steels [for example SS 430, which contains 16 % to 18 % Chromium) and SS 446 containing 23 % to 27 % chromium and duplex stainless steels (22 % to 25 % Cr) are much more susceptible.

In 300 series, alloy SS308 and SS347H have found evidence of 885 °F embrittlement in Charpy impact testing. These alloys weld metals were aged in approx. 850 to 885 °F.

- Higher the ferrite in Duplex stainless steel, higher the risk of 885 °F embrittlement. This is why it is important to control welding conditions when welding duplex stainless steel, especially to have high cooling rate to avoid excess ferrite formation during solidification.

- Embrittlement takes place at only High-temperature exposure. The highest rate of embrittlement occurs at 885 °F. For lower temperature for example at 600 °F or 315 °C, it requires thousands of hours for embrittlement to take place.

- The effect on toughness is not pronounced at the operating temperature but is significant at lower temperatures experienced during plant shutdowns, start-up, or upsets.

- 885 °F Embrittlement can also be caused due to heat treatment in case if the alloy is kept within embrittlement temperature range.

Affected Units or Equipment’s in Refinery

- All susceptible alloys operated at embrittlement temperature range.

- Fractionator trays and internals in high-temperature vessels in FCCU, CDU, VDU etc.

- Duplex stainless-steel heat exchanger tubes.

Appearance or Morphology of Damage

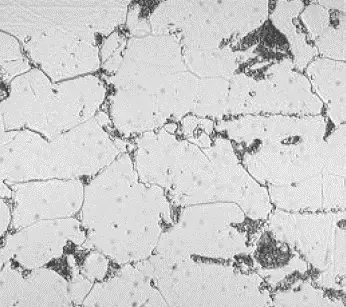

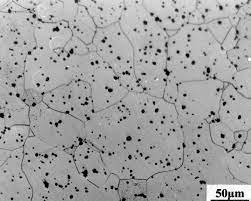

- 885 °F embrittlement is a metallurgical variation that can be found via a metallographic test.

- The existence of 885 °F embrittlement can possibly be identified by an increase in hardness in affected areas. The best method to verify the embrittlement in the material in service is by bend test or CVN impact test.

- Mainly embrittlement issue is observed during plant shutdown or startup as the material transit from high temperature to low temperature and embrittlement is severe at low temperature compared to high temperature where material still behave ductile.

Prevention / Mitigation of Graphitization

- The best approach to prevent 885 °F embrittlement is not to subject the material to this high-temperature range or use a material that is immune to 885 °F embrittlement.

- Using proper start-up and shutdown practice by having a temperature control can avoid the cracking in the suspected embrittled material.

- Heat treatment can be used to reverse the effect of 885 °F embrittlement. For bringing the affected material to its original state, a heat treatment is carried out at a temperature of 1100 °F or 595 °C or higher. The heat treatment is solution annealing that prevent the re-formation of hard phases. The risk is, once this material exposed to high temperature again, the rate of embrittlement will be more faster although.

Inspection and Monitoring

- 885 °F embrittlement is difficult to locate until the part is failed. Due to time dependent failure, it takes time for the material to have embrittlement. Online inspection is not possible for this mechanism.

- The best method to verify the 885 °F embrittlement by bend test or CVN impact test. A sample from affected material need to be cut and tested using bend or impact test to verify the 885 °F embrittlement. If the sample fail then the material is said to be embrittlement.

- VT can also be carried out the check any crack due to 885 °F embrittlement.

- Hardness testing can also be carried out to differentiate between embrittlement and non-embrittlement material. The hardness testing itself can cause cracking in the material depending on severity of 885 °F embrittlement.

- Hammer testing usually carried out in the refineries for corrosion testing should not be carried out in case 885 °F embrittlement. Any impact can make the material to crack eventually. If you reject the embrittlement material, then hammer testing can be carried out as go & no-go check for the affected material.