What is SS310 material?

SS 310 stainless steel is a type of Austenitic Stainless steel with a medium carbon percentage similar to the carbon steel range and used mainly for high-temperature services for example furnace parts, pipelines, and heat-treated components.

The material can withstand up to 2100°F 1150°C for continuous service. 310 type of austenitic stainless steel offers excellent oxidation resistance, good creep properties at high temperatures, and general corrosion resistance.

The low carbon variant of 310 is 310S grade which has good weldability compared to SS310. SS310 is also used for cryogenic temperature services up to the temperature of -268°C (-450°F).

Material Specification

- ASME P. Number: ‘8‘

- Group Number: ‘2‘

The UNS Number of the SS310 material is UNS S31000, for 310S UNS number is UNS S31008 and for 310H UNS Number is UNS S31009. The material is supplied as per the below specifications:

- ASTM: A-240

- ASME: SA-240

- AMS: 5521

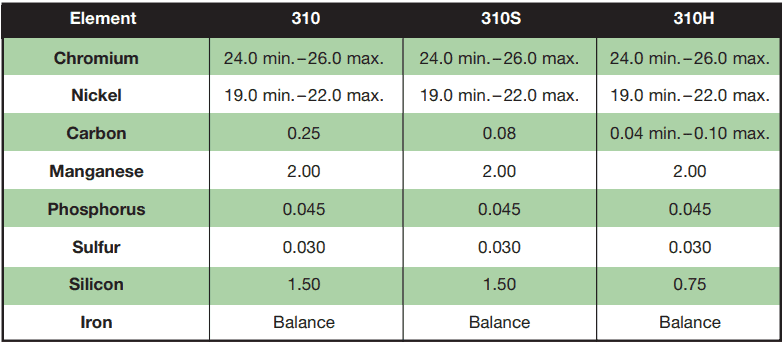

Chemical and mechanical properties of SS310

The chemical properties of SS310, SS310S, and SS310H are shown in the below picture. The main difference between 310, 310S, and 310H is the amount of Carbon%.

SS310S has the lowest carbon i.e., 0.08% maximum while SS310 has the maximum carbon percentage.

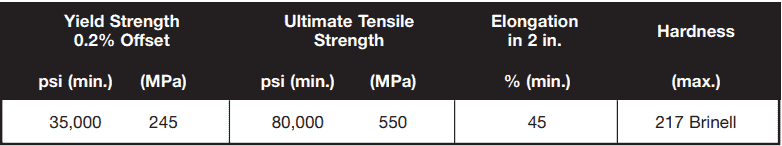

The standard tensile and yield strength of SS310 at 68°F or 20°C i.e., ambient temperature is given in the below table.

The typical hardness of SS310 is 217 HB and elongation is a minimum of 45%, a typical characteristic of austenitic stainless steel.

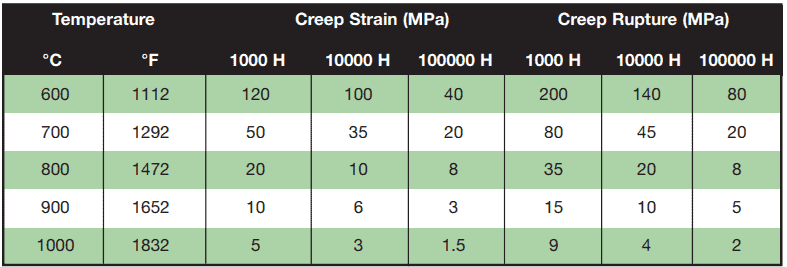

The creep properties of SS310 are given in the below table at various temperatures. The creep strain and creep rupture strength are shown in MPa for 310 stainless steel.

SS310 Temperature Range

SS310 Temperature Range for cryogenic service is up to -450°F (-268°C). The high temperature limit for SS310 is 2100°F 1150°C.

SMAW or Stick Welding of 310 alloy

Stick welding or SMAW welding of SS310 is carried out using the E310-15 electrode. Stick welding of E310H is carried out with an E310H-15 type electrode.

E310H Stick Welding/ SMAW Electrode properties: The chemical composition of the E310H rod is the same as the base metal of SS310 except for the carbon percentage which is 0.35% to 0.45%. E310H stick welding rods are mainly for welding SS310 material.

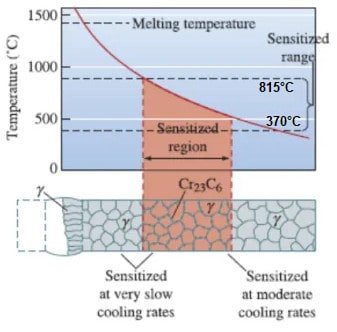

When the 310 or 310H material is exposed to high temperature (in the temperature range of 1202–1742°F (650–950°C) it gets sigma embrittlement.

The one solution to regain its ductility back is by solution annealing but often it’s not feasible to do so at sites or big vessels made of SS310 material.

In these cases, any welding work or repair shall be carried out with the E16-8-2 electrode only. E16-8-2 stick welding electrodes offer high crack resistance compared to E310-XX type electrodes.

310 Stainless Steel Tig Wire

310 Stainless Steel Tig Wire for welding is ER310 (AWS A5.9). Other Filler wire for welding 310 stainless steel using TIG wire is ER16-8-2 (AWS A5.9). More details on this are covered below.

TIG-MIG welding of SS310

TIG or MIG welding of SS310/ SS310H/SS310S material is carried out using ER310-type filler wire as per SFA 5.9. ER16-8-2 is also used for materials exposed to high temperatures.

ER16-8-2 is also suitable for welding new materials without any concerns. Flux core welding (FCAW) is carried out using SFA 5.22-E310T-X type cored wire.

Pure argon is usually used for shielding purposes. To know more about Shielding gases of TIG MIG and FCAW welding of stainless-steel duplex steel, Click here.

When welding open root with TIG or MIG gas purging is required and needs to be pure inert gas to avoid the oxidation of the root side.

Read more: Difference between gas shielding, gas purging & gas trailing?

Welding of SS310 to Carbon Steel

SMAW or stick Welding of SS310 to carbon steel is carried out using E309L-15/16/17 or with AWS SFA/A 5.11, Classification ENiCrFe-2 or -3 or ENiCrMo-3 type electrodes.

Welding 310 to 304 or 316 Stainless

Welding of SS310 to SS304 or SS316 stainless steel is carried out using AWS SFA 5.4, Classifications E309-15/16/17 or E309L-X 15/16/17.

Click here to know the Difference between E309L-15, 16 17, E316L-15,16 and 17

Preheating & interpass temperature

Preheating is generally not required for welding 310 material either its S310S or 310H. Interpass temperature shall be kept to a maximum of 400°F or 200°C. It is recommended to use low heat input to avoid deformation during SS310 welding.

Material exposed to high temperature and prone to have sigma embrittlement will lack ductility. So, preheat can be applied to these materials to avoid cracking during welding.

PWHT of SS310

PWHT of SS310 is not required. The heat treatment process used only is solution annealing at 1832–2101°F (1000–1150°C) to restore material ductility and original microstructure when it is exposed to high temperatures.

Sigma embrittlement in SS310

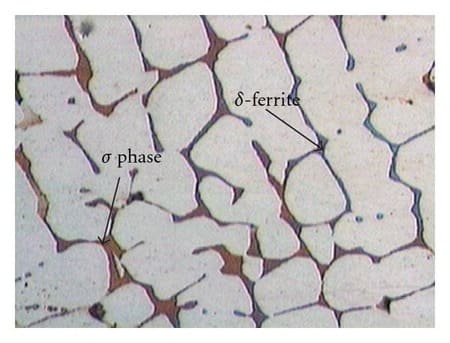

SS310 alloy when exposed to a temperature range of 1202–1742°F (650–950°C), the microstructure is prone to sigma phase precipitation (? phase) due to the high carbon present in the material.

Sigma phases are hard microstructures that reduce material ductility. A high amount of sigma precipitation in the material will make it brittle & reduce toughness and the material can easily crack if any impact is applied to the materials.

To overcome the effect of sigma embrittlement, a heat treatment known as solution annealing heat treatment is applied to the material at the temperature range of 2010-2100°F (1100–1150°C) to restore back material ductility and toughness.

310 Welding Rod Uses

310 Welding Rod uses are:

- Welding of SS310 grade materials.

- Welding of SS310S materials.