What is A36 Steel?

A36 steel is a Carbon Steel supplied according to the SA-36 or ASTM A36 (American specification) material specification.

The materials are available in various shapes, plates, and bars of structural quality. A36 material is commonly used for making general fabrication, welding structural works, in shipbuilding & oil- Gas.

The equivalent of A36 material is S275 (As per EN10025, European material specification), where S stand for structural steel. IS2062 in India also equivalent to A36 material.

For welding, The P Number of A36 material is P1 and the Group Number is G-1.

What is P-Number in Welding and ASME?

What is Group-Number in Welding & ASME?

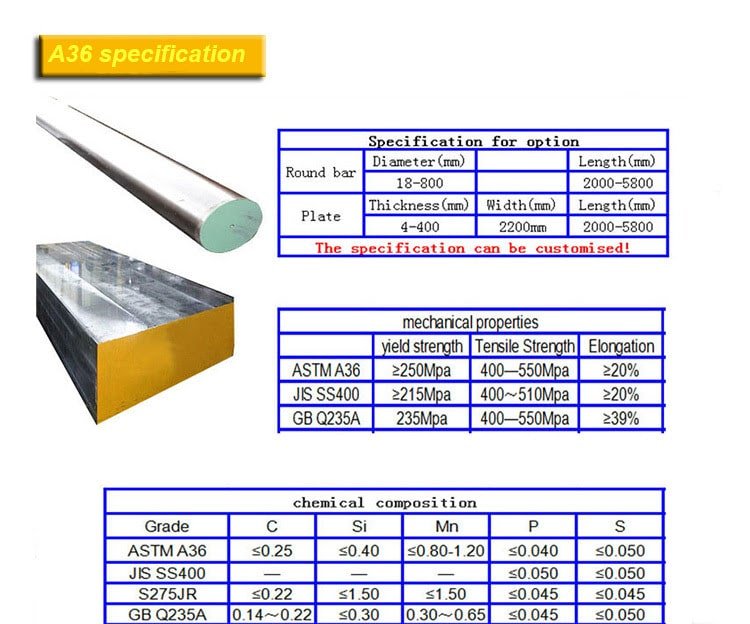

Chemical and mechanical properties of A36 material

The Tensile strength of A36 material in ksi is 58–80 while in MPa is 400–550. The Yield point or Yield Strength is 36 ksi or 250 MPa.

The detailed material equivalent of A36 material, their grade, and chemical and mechanical properties are shown below.

Welding of A36 Material

SMAW or stick welding of A36 to A36, A36 to SA516 or SA106 or any other carbon steel shall be made using E7018 or E6013 type electrodes.

TIG or MIG welding of A36 to A36, A36 to SA516 or SA106, or any other carbon steel shall be made using ER70S-6 or ER70S-2 type solid wire.

Preheating is not required usually although for higher thickness, preheat of 150 to 200 Deg F is beneficial to avoid distortion.

Welding of A36 Material to Stainless steel or Duplex Stainless Steel

Welding of A36 to SS304 or SS316 or any other stainless steel shall be made using an E309L type SMAW electrode. TIG or MIG welding can be carried out using ER309L type filler wire. No special precaution is needed when joining these combinations.

It is recommended to avoid high heat input which can otherwise be detrimental to the stainless steel or Duplex stainless steel material. Use of stringer bead is recommended.

To Learn More About various dissimilar welding, Click below:

How to weld stainless steel to mild steel

Welding Electrode/ Filler wire/ Filler metal Selection Chart

Preheat, Interpass and PWHT

No preheat is required unless you are welding at a temperature below 5 Degree Celsius or 40 Degree Fahrenheit.

The higher thickness of carbon steel material can be preheated as stated above. No preheat is required for austenitic stainless steel or duplex stainless steel material.

Use Online Welding Preheat Calculator to Calculate preheat temperature for welding.