What is Hardox 400 material?

Hardox 400 is abrasion-resistant steel material created by the SAAB company having a hardness value of 400 HBW or 589 HV or 54 HRC level. The hardox material provides high hardness for abrasion resistance, has good toughness, ductility and weldability.

Material Specification

Material specification of Hardox is EN 10029, EN 10051.

Hardox 400 equivalent

There are a number of different steel grades that are equivalent to Hardox 400. These include:

- Abrazo 400,

- Fora 400,

- Q345B and

- Dillidur 400.

All of these steels offer excellent wear resistance, making them ideal for applications where abrasion is a concern.

Hardox 400 is typically used in construction and mining equipment, as well as in dump trucks and excavators.

It can also be used in a variety of other applications where wear resistance is important.

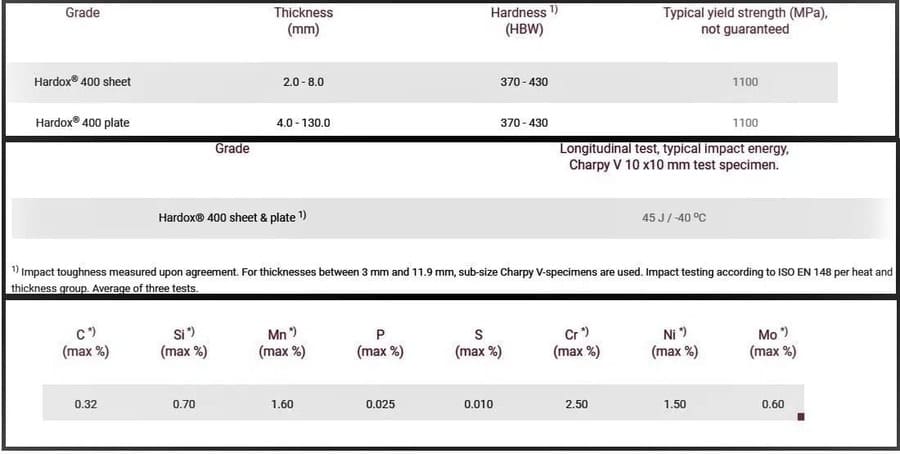

Chemical and mechanical properties Hardox 400

The chemical and mechanical properties of Hardox 400 material are given in the below Table.

| C% | Si% | Mn% | S% | P% | Cr% | Ni% | Mo% |

|---|---|---|---|---|---|---|---|

| 0.32 | 0.70 | 1.60 | 0.010 | 0.025 | 2.5 | 1.5 | 0.6 |

The hardness range for Hardox 400 is 370- 430 HBW for sheet and plates.

The typical yield strength of hardox 400 is 1100 MPa with a toughness requirement of 45 Joules at -40 Deg C.

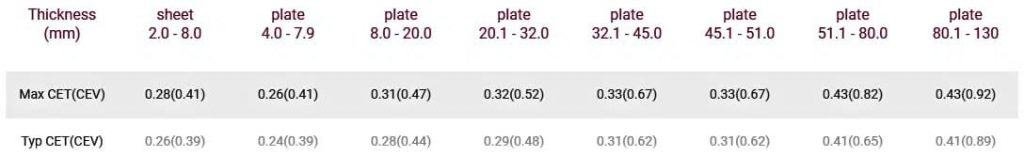

Carbon Equivalent for Hardox 400 Steel

The CE Value of Hardox 400 is usually dependent on the material thickness.

The CE value increase with the increase in plate thickness. The hardox CE value can be 0.41 to 0.92 as given in the below table.

Hardox Welding Rods for Hardox 400

Hardox welding can be carried out using different welding processes. The most common hardox welding are SMAW, TIG and MIG Welding.

SMAW or stick Welding of Hardox 400 can be done using E7018 or E8018 type electrode.

TIG and MIG welding of Hardox shall be done using ER70S-6 or ER80S-G type consumables.

These low alloy or carbon steel consumables have low hardness thus good to weld hardox to avoid hydrogen cracking during welding.

The final layer or also called the capping layer needs to be deposited using hard metal (Hard facing) which needs to be having similar hardness to Hardox material. Usually, Hard facing is one on the top surfaces for this purpose.

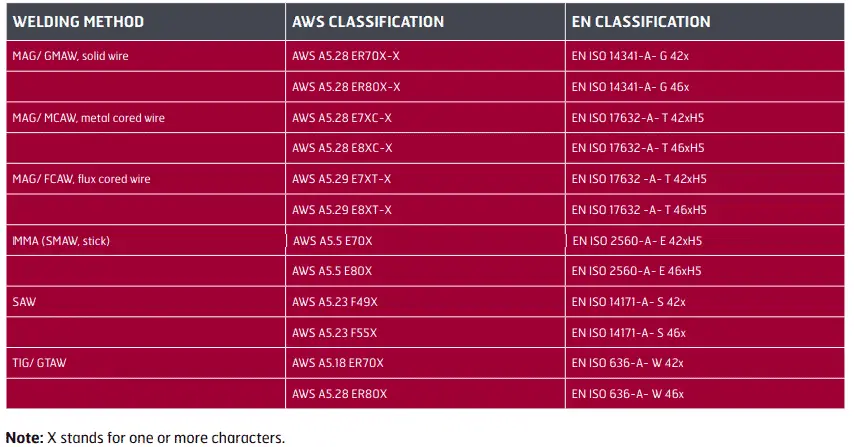

Hardox welding: Welding electrode for hardox 400

The below table gives the summary of welding consumables for Hardox welding.

Welding hardox to mild steel

Welding hardox to mild steel can be done using one of several methods.

Hardox is a wear-resistant material, but it is also brittle. Mild steel is less wear-resistant, but it is tougher. When welding the two materials together, it is important to take into account their different properties.

The first step in welding hardox to mild steel is to prepare the surfaces of both materials.

Carry out the welding of hardox to mild steel using E7018 rod or ER70S-2 TIG-MIG filler wire rod.

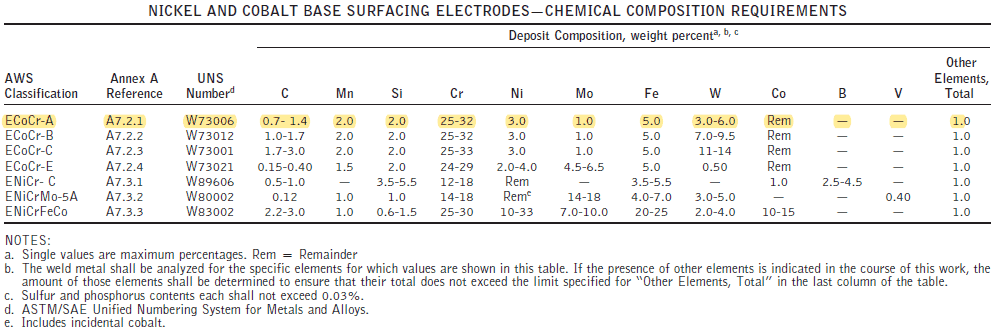

Hard Facing consumables for Hardox material

Different types of consumables can be used for hard-facing Hardox materials such as Iron base, Nickel and Cobalt base, and copper base.

A summary of mostly used Nickel and cobalt base consumables is given in the below table.

More details about these consumables can be found in ASME Section IIC, SFA 5.13.

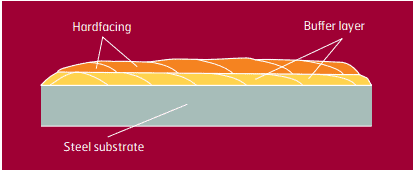

Before depositing the hard-facing weld metal, it is advised to weld a buffer layer of E307 or E309L (SFA 5.4) with SMAW or stick welding.

TIG or MIG welding buffer layer can be deposited using ER307 or ER309L according to SFA 5.9 as shown in the below figure.

The selection of electrodes for hard facing is based on the hardness value required for the weld deposit.

The usual weld hardness of multilayers weld deposits with cobalt-base Stick Welding or SMAW rods are:

1. ECoCr-A 23–47 HRC

2. ECoCr-B 34–47 HRC

3. ECoCr-C 43–58 HRC

4. ECoCr-E 20–32 HRC

Hardness values for single layer deposits will be lower because of dilution from the base metal.

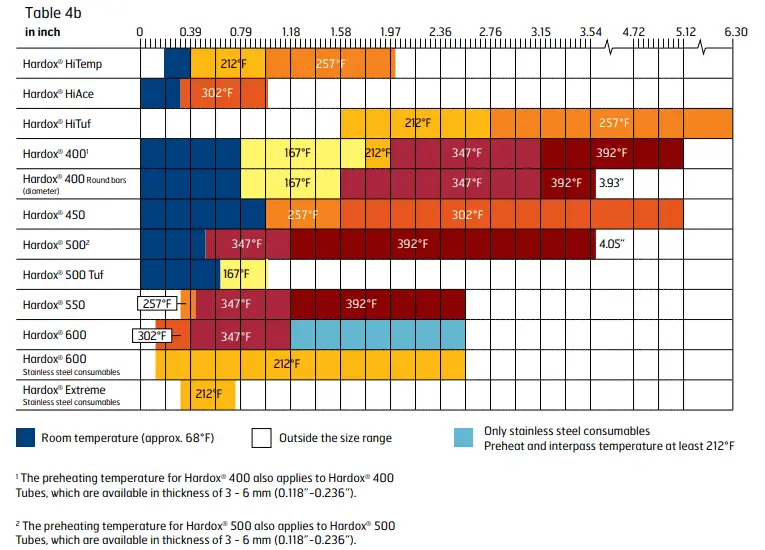

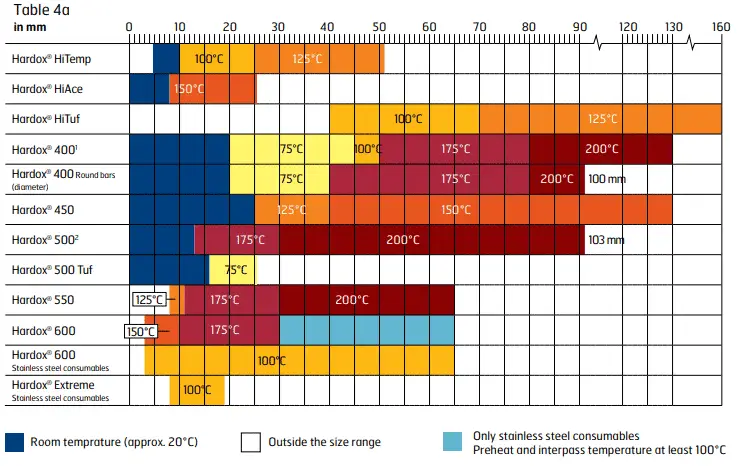

Hardox welding Preheat and interpass temperature

Preheat and interpass temperature control are very important for Hardox welding.

Due to their high carbon equivalent, they are very prone to weld cracking. so high preheat is usually required.

Preheat temperature for Hardox material is given in the below table in inches Fahrenheit.

The temperature is dependent on material thickness. The higher the thickness, the higher the preheat temperature.

The below table gives the temperature in mm-Celsius.

Post-Heating of Hardox material

Post heating of hardox 400, 500, or other materials is not required and also not recommended.

As PWHT can change the mechanical properties of the base material.