Knowing how to weld 17-4 PH stainless steel is very important as this alloy requires careful welding consideration, right welding filler wire & PWHT for desirable weldment properties.

What is Precipitation Hardened Stainless Steel?

Precipitation-hardening stainless steels, often designated with the suffix PH, are types of stainless steels that get their strength from precipitation reactions.

17-4 PH steel is alloyed with controlled elements that form fine precipitates when heat treated. Hardening of most of these steels is also accomplished by the formation of martensite.

They are grouped into:

- martensitic,

- Semi-austenitic, and

- austenitic.

17 4 ph Stainless Steel

17 4 ph Stainless Steel is a high strength, corrosion resistant steel that is widely used in the aerospace, chemical, and oil & gas industries. It is easily welded and formed, making it an ideal choice for many applications.

This versatile steel has a wide range of properties that make it an excellent choice for a variety of applications. It is highly corrosion resistant, making it ideal for use in the aerospace and oil & gas industries.

Additionally, it has a high strength-to-weight ratio and is easily welded and formed, making it suitable for many different applications.

17 4 PH is a martensitic precipitation hardened stainless steel having high tensile strength, corrosion resistance, toughness, and good machinability up to 600°F (316°C). You can find 17 4 PH in semi-austenitic grade also & this is obtained by minor chemistry change in the alloy.

Delivery Specification for 17 4 PH Steel

The material specification for 17-4 PH is ASTM A693 (Grade 630 UNSS17400), AMS 5604. The UNS Number of 17-4 PH is UNSS17400.

17-4 PH is an unclassified material, hence no P-Number as per ASME Section IX or AWS D1.6.

17 4 ph stainless steel chemical composition

The nominal compositions of 17-4 PH grades are given in the below table:

| Martensitic type | ||||||||

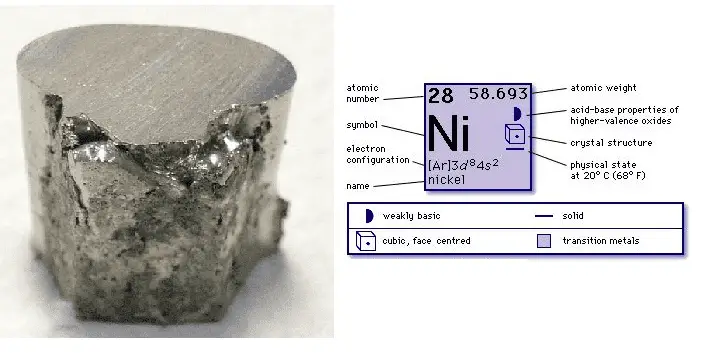

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | Cu% | Nb% |

| 0.07 | 1.00 | 1.00 | 0.040 | 0.030 | 15- 17.50 | 3-5 | 3-5 | .015-.045 |

| Non-Martensitic type | ||||||||

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | Al% | Cu/ Nb |

| 0.09 | 1.00 | 1.00 | 0.040 | 0.030 | 16- 18 | 6.5-7.75 | 0.75-1.50 | 00 |

17 4 ph Hardness Range

17 4 ph is a precipitation hardening stainless steel that can be heat treated to a wide range of hardness values.

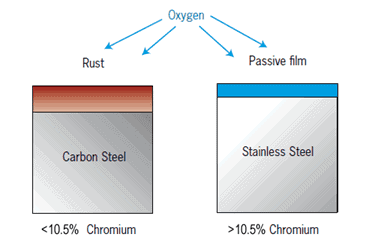

It has a high chromium content and is often used in applications where corrosion resistance is important.

17 4 ph is typically supplied in the annealed condition and can be hardened by a variety of methods, including age hardening and heat treating.

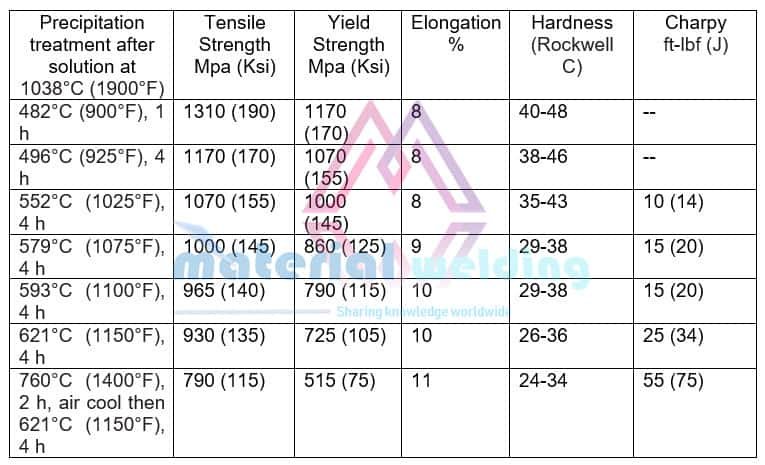

The 17 4 ph hardness range is typically from 24 to 48 HRC depending upon the precipitation treatment temperature after solution annealing as given in table later in this post.

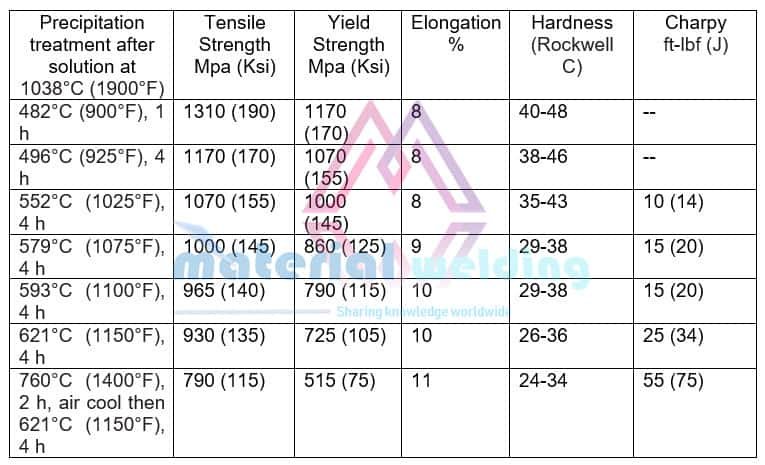

Mechanical properties vs. heat treatment conditions:

The mechanical properties of 17-4 PH stainless steel depend on precipitation treatment. Table 2 shows the various precipitation treatment temperatures and their corresponding mechanical properties of 17-3 PH grade material.

The hardness of 17-4 PH also depends on the heat treatment. The maximum hardness of40- 48 HRC for 17-4 PH is obtained by precipitation treatment at 482 Deg C after solution annealing.

A detailed hardness chart for 17-4 PH at various heat treatment temperatures is given below.

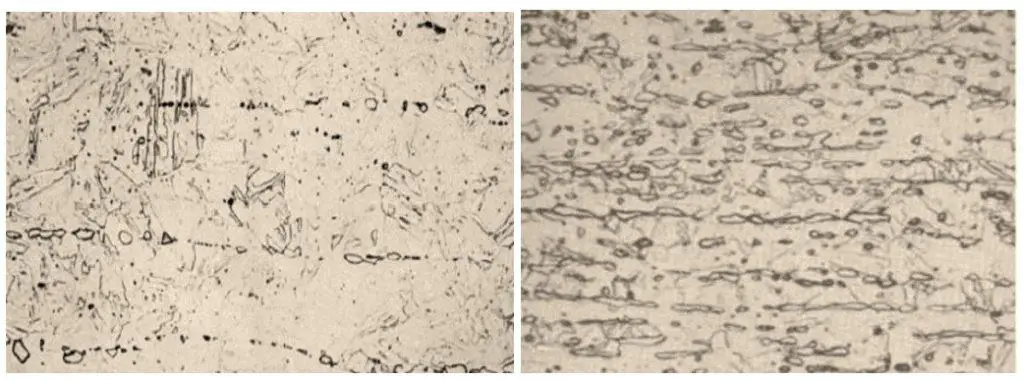

Microstructures of hot rolled 17-4 PH stainless steel (martensitic type) & 17-7 PH stainless steel (Semi-austenitic type)

17-4 PH Welding Consideration: How to weld 17-4 PH stainless steel

- When welding 17-7 PH or 17-4 types, higher heat input is advised to obtain high dilution. By this, 17-7 PH steel will get a reasonable heat treatment response due to base metal dilution.

- A short arc during welding shall be used to minimize the oxidation, loss of chromium, and nitrogen pickup from the atmosphere.

17-4 PH Metallurgy consideration

MS Temperature: 132°C (270°F),

Mf Temperature: 32°C (90°F)

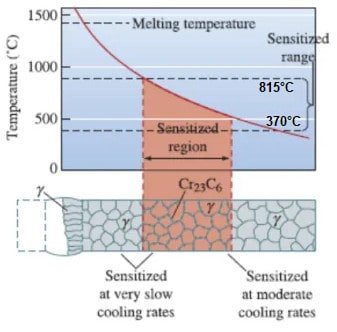

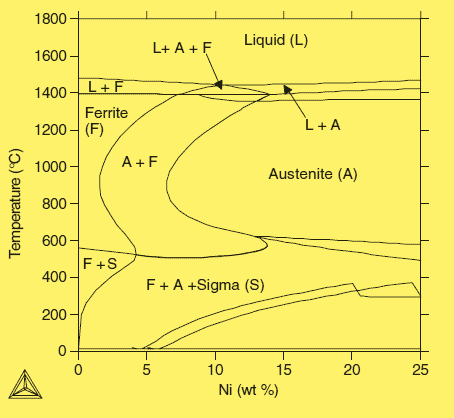

The martensitic and semi-austenitic precipitation-hardening stainless steels solidify as primary ferrite in either the FA or F mode as shown in the below figure.

It can be seen that they all solidify as virtually 100% ferrite. During solidification, ferrite converts to austenite however slight residual ferrite can remain in the microstructure after solidification.

Although, during welding of 16-4 PH material, most of the austenite will convert to martensite.

Welding of PH steels shall be done in the solution-treated condition before precipitation takes place. At this tage, the martensitic type PH stainless steels are little hard but still somewhat ductile.

Because the weld metal cools rapidly, virtually no precipitation normally occurs in the weld metal, so that in the as-welded condition, the weld metal is not unlike the solution-annealed base metal in terms of its microstructure and properties.

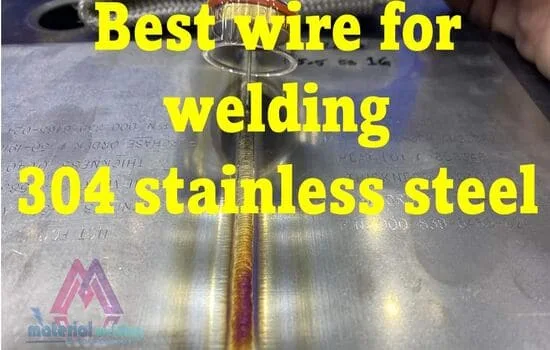

Best Welding consumables/ rod for 17-4 PH:

The best welding rod for 17-4 ph stainless steel is an E630 stick welding or SMAW rod and ER17-4 PH / ER308 is used for TIG/ MIG welding of 17-4 PH steel.

👉👉👉👉Get Welding Metallurgy and Weldability of Stainless Steels Book👉👉👉👉

17-4 PH can be successfully welded using Stick welding (SMAW), GTAW & GMAW processes.

Usually, after welding, 17-4 PH steel is heat-treated by full solution heat treatment and aging (Precipitation treatment).

17-4 Welding:

Stick Welding or SMAW welding of 17-4 PH is carried out using an E630 rod. For TIG and MIG Welding of 17-4 PH, the suitable welding rod/ filler wire is ER17-4 PH and ER308.

The table below shows the welding electrodes and filler wires combinations:

| Designation | UNS Number | SMAW Electrode | Solid wire (GTAW/GMAW) | Dissimilar welding of 17-4PH to SS/ CS |

| Martensitic types PH-steel | ||||

| 17-4 PH or 15-5 PH | S17400/ S15500 | E630 (17-4PH) or E308 | 17-4 PH or ER308 | E/ ER309 or E, ER309 Cb |

| Semi-Austenitic types PH-steel | ||||

| 17-7 PH | S17700 | E630 (17-4PH) or E308 | 17-4 PH | E/ ER310, ENiCrFe-2 or ERNiCr-3 |

Welding 17-4 PH to carbon steel & SS304, SS316L

Welding of 17 4 PH to carbon steel is carried out using an E309L type stick welding rod. TIG/ MIG welding of carbon steel to 17-4 PH can be done using ER309L.

Stick Welding or TIG/ MIG Welding of 17 4 PH to SS304L or SS316L is carried out using Er309L or ENiCrFe-2 or ERNiCr-3 type welding rod and filler wire.

Preheating for 17 4 PH Steel Welding

Preheating in the range of 150 to 200 degrees C is recommended to avoid any weld cracking issues.

17-4 PH PWHT after welding:

Improving the strength of 17 4 PH steel is a critical process and it needs precise control of the heat-treatment process.

The martensitic alloys, after welding, are usually given a single PWHT in the range of 480 to 620°C (900 to 1150°F).

This heat treatment both tempers the martensite and promotes precipitation strengthening.

At high PWHT temperatures [over 540°C (1000°F)], some austenite may re-form in the final structure.

17 4 ph stainless steel heat treatment

17-4 PH stainless steel is a precipitation hardening martensitic stainless steel. It combines high strength, hardness, and corrosion resistance.

17-4 PH can be heat treated to a wide range of mechanical properties. The mechanical properties of 17-4 PH stainless steel depend on the heat treatment temperature and time.

The heat treatment for 17 4 ph stainless steel is quite simple. The steel is first solution heat treated at 1050°F (566°C) for one hour. This step provides uniformity to the microstructure and should not be used to change the properties of the alloy.

After solution heat treating, alloy is subjected to precipitation treatment at different temperature range to meet required properties. The main heat treatment for 17-4 PH is precipitation hardening. This heat treatment is carried out after solution annealing of the material.

Find here detailed heat treatment requirements for 17-4PH stainless steel.

17-4 ph heat treat chart

The detailed precipitation treatment temperature and corresponding mechanical properties are given in below 17-4 heat treat chart. The hardness range for 17 4 ph stainless steel is from 24 HRC to 48 HRC.

17-4 hardness chart

The 17-4 hardness chart is a valuable tool for anyone working with this versatile alloy.

This precipitation hardened stainless steel is widely used in the aerospace, petrochemical and nuclear industries due to its high strength and corrosion resistance.

The chart lists the nominal hardness values for various tempers of 17-4 stainless steel.

17 4 ph stainless steel corrosion resistance

17 4 ph stainless steel is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium.

17 4 ph stainless steel has high strength and hardness properties, and good corrosion resistance. The alloy is double tempered to achieve a wide range of mechanical properties.

17 4 ph stainless steel is widely used in the aerospace, chemical, and petrochemical industries for its high strength and good corrosion resistance. The alloy is also used in the medical, food processing, and marine industries.

It has a low carbon content for a martensitic stainless steel, which enhances its weldability. In addition, it contains between 3% and 5% nickel, which improves its corrosion resistance.

And finally, it contains between 15% and 18% chromium, which gives it good overall corrosion resistance.

17 4 ph stainless steel tensile strength

17 4 ph stainless steel tensile strength is 115 Ksi (790 MPa) to 190 Ksi (1310 MPa).

17 4 ph stainless steel Mechanical properties can be optimized with heat treatment. Very high yield strength up to 790-1300 MPa can be achieved based on heat treatment temperature as shown in chart earlier.