AISI 4140 Steel Welding Procedure

AISI 4140 Steel Welding can be carried out using SMAW (Stick Welding), TIG, MIG and FCAW process. Stick welding of AISI 4140 is carried out using E8018-B2 or E7018 electrode while TIG or MIG welding is carried out using ER80S-B2 or ER70S-2 welding wire. Check this article for detailed guidelines for welding 4140 steel including preheat & interpass temperature and post weld heat treatment procedure.

AISI 4140 is high-strength medium carbon steel. 4140 can be easily welded with the right precautionary steps being applied. Other steels in this category as AISI 4130 (AISI 4130 Welding Procedure) and 4340 (AISI 4340 Welding Procedure) follow the same welding advice.

This article provides a detailed introduction to the AISI 4140 materials, their properties, welding, and PWHT requirements.

What is AISI 4140 steel?

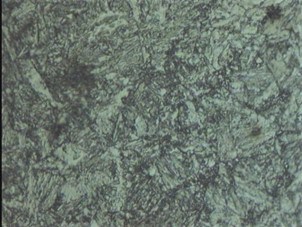

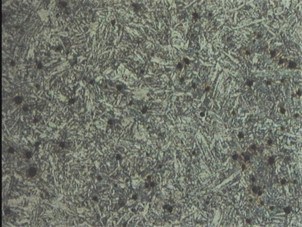

AISI 4140 is a Cr-Mo-Mn-based high strength low alloy steel offering high fatigue strength, toughness, abrasion & impact resistance. Being a medium carbon steel range, AISI 4140 gets hardened during welding repair especially in the heat-affected zones (HAZ) due to thermal cycles and microstructural transformation along with locked residual stresses produced by the welding heat.

This results in the formation of bainite and martensite depending on the cooling rates. The high hardness in the HAZ is associated with the locked residual stresses and the martensite transformation of the AISI 4140 microstructure.

Material Specification for supply for AISI 4140

ASTM A322, ASTM A331, ASTM A506, ASTM A513, ASTM A519, ASTM A646, ASTMA752, SAE J404, SAE J412, SAE J1397 etc.

4140 Steel Equivalent

The 4140 steel equivalents are 42CrMo4, SCM440, and 1.7225. These three alloys are very similar in terms of their chemical composition and properties. They are all high-strength steels that can be heat treated to achieve a wide range of hardness levels. The 4140 alloy is the most widely used of the three, and it is typically used in applications where strength and toughness are required.

Chemical properties of AISI 4140 (4140 steel properties)

The table below shows the typical chemical properties of AISI 4140 steel material in as supplied conditions. The material is usually available in quenched and tempered condition and designated as AISI 4140HT. Although it’s available in annealed condition too.

4140 steel carbon content is a maximum of 0.40%, silicon maximum of 0.30%, Mn 0.88%, Cr 1.10%, and Mo 0.24% maximum.

| Carbon | Si | Mn | Cr | Mo | S | P |

| 0.40 | 0.30 | 0.88 | 1.10 | 0.24 | 0.015 | 0.021 |

Weldability of AISI 4140 (4140 Steel Welding)

Being Low alloy steel along with high carbon content & high carbon equivalent (C.E.) of around 0.8, welding becomes a challenge due to the propensity of high hardness in the heat-affected zone and weld metal resulting in weld cracking (Types of Crack in Welding & their prevention) If the right precautions are not considered.

Can 4140 be welded?

Yes, 4140 steel can be easily welded when right welding procedure is followed. We have welded a lot of 4140 steel successfully ranging from shafts, pipes and tubing materials. I have qualified 4140 steel welding procedures for various clients using SMAW, TIG, FCAW and SAW processes.

The figures show the typical microstructure of AISI 4140 material and weld metal.

How to weld AISI 4140 Steel (AISI 4140 Welding Procedure)

What welding rod to use on 4140 steel?

We recommend to use E8018-B2 or E7018 welding rod for 4140 steels when welding with Stick or SMAW Process. while TIG or MIG welding is required for 4140 steels, use ER80S-B2 or ER70S-2 welding wire.

Chrome-Moly wire as mentioned above match the chemistry of the 4140 steel and also provide similar microstructure as the base metal. Hence, as per my understanding, E8018-B2 or ER80S-B2 is the best welding rod for 4140 steel.

Continue this post for more in-depth information on welding 4140 steel to other materials.

Selection of Welding Consumables:

The selection of filler wire is based on the chemical and mechanical properties of the AISI 4140 material. The best filler wire or electrode is E8018-B2 for stick welding or SMAW electrode or ER80S-B2 when welding with TIG (GTAW) or MIG (GMAW).

👉👉👉👉👉Buy ER80S-B2 TIG & MIG Welding Wire👉👉👉👉👉

The table below shows the typical chemical properties of ER80S-B2 filler wire.

| Carbon | Si | Mn | Cr | Mo | Ni | S | P |

| 0.07- 0.12 | 0.4- 0.70 | 0.4- 0.70 | 1.2- 1.50 | 0.40- 0.65 | 0.20 | 0.025 | 0.025 |

The AISI 4140 can also be successfully welded using E7018, ER70S-2 (undermatching consumables), or other most common carbon steel welding consumables although they result in softer weld metal as well as reduced mechanical properties of the weld compared to AISI 4140.

Stick/ SMAW Welding of AISI 4140

Stick welding or shielded metal arc welding (SMAW) of AISI 4140 is carried out using the E7018 or E8018-B2 electrodes. E8018-B2 offers a similar to the 4140 base metal alloy deposit weld.

While welding with E7018, remember it will provide a softer weld metal compared to AISI 4140 material. Also, note that all low-hydrogen type electrodes shall be properly baked prior to use as per the recommendation stated in AWS A5.1 or AWS A5.5 welding electrode specification.

Check out my this article to guide you on Recommended baking-dring temperatures and guidelines for welding electrodes.

TIG/ MIG Welding of AISI 4140

TIG or MIG welding of AISI 4140 shall be carried out using ER80SB-2 or ER70S-2 depending on the requirements. For material that requires similar weld composition as base metal, it is good to weld using ER80S-B2. For a simple joining application, welding is carried out using ER70S-2 TIG/ MIG filler wire.

Preheating for AISI 4140 Welding:

AISI 4140 steel must be preheated to avoid the:

- Formation of hard microstructures such as martensite and Bainite in the weld and HAZ.

- Allow weld to slow cool thus helping to release residual stresses.

- Allow the release of weld metal hydrogen to eliminate hydrogen cracking risk.

The AISI 4140 steel is recommended to preheat:

- Up to ½ inch (12 mm) thickness: 400- 500℉ (200- 250℃ approx.)

- Above ½ inch (25 mm) thickness: 500- 600℉ (250- 300℃ approx.)

The above preheat temperature is based on the recommendation given in Welding handbooks such as ASM and AWS. You can use our Online Welding Preheat Calculator to find the right preheat temperature for a variety of materials based on alloy chemistry, plate thickness, and hydrogen level.

Watch our YouTube video to Learn what is Preheat, Inter-pass & post-heating.

Interpass Temperature for AISI 4140 Welding:

Usually, the interpass temperature is kept above the minimum preheat temperature. In no case, the interpass temperature shall be allowed to cross the tempering temperature of the supplied materials as it will damage the material properties.

After Weld Finish:

Allow the welding area to slow cool using a heating blanket is a good practice. It will prevent fast cooling thus preventing any weld cracking, supporting soft microstructure, and removing hydrogen from the weld.

Welding AISI 4140 to 1045 & 1018

Welding of AISI 4140 to 1045 or 1018 material can be carried out using an E8018-B2 stick welding rod or E7018 type electrode. All low hydrogen electrodes must be baked prior the use. TIG (GTAW) or MIG (GMAW) welding of AISI 4140 low alloy steel to 1045 material, 1018 material and ASTM A36 (Carbon steel) is carried out using ER80S-B2 or ER70S-2 type filler wire.

Click here for Welding Rod sizes and amperage chart.

Preheating is required for AISI 4140 side material only. Although, it is beneficial to preheat the 1045 material, 1018 material and A36 material in case of thicker materials only. The reason is to provide a slow cooling due to the high thickness. Interpass temperature control shall be followed as stated earlier.

Welding of AISI 4140 to A36 (Welding 4140 to mild steel)

Welding of AISI 4140 to A36 (4140 to mild steel) can be carried out using an E8018-B2 stick welding rod or E7018 type electrode. All low hydrogen electrodes must be baked prior the use.

TIG (GTAW) or MIG (GMAW) welding of AISI 4140 low alloy steel to ASTM A36 (Carbon steel) is carried out using ER80S-B2 or ER70S-2 type filler wire. Preheating is required for AISI 4140 side material only.

Although, it is beneficial to preheat the A36 material in case of thicker materials only. The reason is to provide a slow cooling due to the high thickness. Interpass temperature control shall be followed as stated earlier.

Post Weld Heat Treatment of AISI 4140 Steel:

PWHT is a process that is performed after welding to relieve stress in the material. It involves heating the steel to a specific temperature and then cooling it at a controlled rate.

Stress relieving 4140 after welding

Post weld heat treatment of AISI 4140 steel shall be carried out from 1225 to 1275℉ (660- 690℃). In case the material is quenched, and tempered (Q & T), the PWHT temperature shall be below the tempering temperature usually 50 to 60℉ (10- 15℃) below it.