Welding 4130 Chromoly Steel

Welding 4130 steel or Chromoly is not difficult, provided welding procedures and subsequent post-weld heat treatment (PWHT) are carried out in accordance with approved procedures.

When welding 4130 steel, it is important to use the correct electrode, right preheat and interpass temperature and suitable heat treatment.

AISI 4130 Steel aka Chromoly Steel

AISI 4130 alloy steel contains chromium and molybdenum to work as strengthening elements.

It is available in the market as a round bar usually in the Quenched and tempered condition having a hardness of 18-22 HRC. AISI 4130 Q &T low alloy steel is used in oil & gas drilling and production components such as wellhead and Christmas tree parts.

AISI 4130 is made with high carbon and added chromium and molybdenum. The alloy responds very good to heat treatment and it is possible to achieve a high strength with toughness using the right heat treatment process.

AISI 4130 Material Specification

Material specification for AISI 4130 steel are AMS 6350, 6360, ASTM A331, ASTM T506, 507, A518 etc. The UNS Number for AISI 4130 steel is UNS G41300.

AISI 4130 Chemical Properties

AISI 4130 contains 0.28 to 0.33% carbon, 0.8o to 1.1% Chromium and 0.15 to 0.2% molybdenum as main alloying elements. These are also the main elements that affect the weldability of AISI 4130 material.

| Percentage | Carbon | Silicon | Mn | Chromium | Moly | Sulfur | Phosphorus |

| Minimum | 0.28 | 0.15 | 0.40 | 0.80 | 0.15 | 0.00 | 0.00 |

| Maximum | 0.33 | 0.35 | 0.60 | 1.10 | 0.25 | 0.035 | 0.025 |

Mechanical Properties of AISI 4130

NACE MR0175: maximum hardness of 22 HRC as per API 6A. The Tensile strength and Yield Strength of 4130 steel are given below.

| Properties | MPa | Ksi |

|---|---|---|

| Tensile strength, | 560 MPa | 81.2 |

| Yield strength, | 460 MPa | 66.7 |

Welding of AISI 4130

AISI 4130 is having very high tensile & yield strength due to its quenched and tempered (Q & T) conditions.

When welding with the SMAW electrode, the matching or higher properties are achieved with the E10018-D2 electrode.

GTAW (TIG) or GMAW (MAG) welding shall be done using ER100S-G type filler wire. These electrode or wires gives higher mechanical properties than the base metal for AISI 4130 welding.

AISI 8620 (21NiCrMo2) welding procedure & guidelines

4130 Filler Rod

One of the most important things to consider when welding 4130 steel is what type of filler rod or wire to use.

For 4130 steel, the recommended filler rod is ER100S-G. This TIG welding filler rod is made specifically for 4130 steel that provides a high tensile & yield strength for the welding joint.

4130 Tig Rod

ER100S-G is a TIG welding rod specifically designed for welding 4130 steel. It has a low carbon content which makes it ideal for welding thin sections of 4130 without the risk of cracking or other issues if right preheat is applied.

ER100S-G TIG rod is available in a range of diameters, so it can be used for both thick and thin sections of 4130 steel. It can also be used on other low alloy steels such as 4140 and 4340.

AISI 4130 Weldability

AISI 4130 weldability is achieved by preheating prior to welding, keeping recommended interpass temperatures during welding, and post heating after welding.

This alloy is particularly prone to hydrogen cracking, which can be minimized by using an appropriate filler metal and ensuring that the weldment is properly cooled.

Preheating prior to welding is necessary in order to avoid cracking. The recommended preheat temperature for AISI 4130 is between 400-570°F (200-300°C).

The upper end of this range should be used when welding thicker sections (>1 inch/25 mm), or when operating in a cold environment. Slower cooling rates after welding will also help to reduce the risk of cracking.

The use of an appropriate filler metal is important for preventing hydrogen cracking. Following point should be considered for 4130 weldability:

- Meeting NACE MR0175 hardness limits for low alloy steel as the maximum hardness allowed is 250HV. Careful selection of the preheat & post heat (Stress relieving) temperature is a critical step.

- Avoid hydrogen cracking by ensuring fully baked welding consumables.

- Produce a ductile & high-strength weld metal.

Welding 4130 to Mild Steel

Welding 4130 to Mild steel materials such as EH36, SA516, or SA105 can be carried out using TIG/ MAG filler wire ER70S-6 or SMAW electrode E7018.

If a high-strength filler is needed, welding can be done with E10018-D2 or ER100S-G filler wire.

Preheat of AISI 4130 steel

preheat temperature shall be kept around 200 Deg C to 250 Deg C ( 400-570°F) for AISI 4130 material. Click here to use our Free online Preheat temperature Calculation tool.

4130 steel Heat Treatment

Heat Treatment of AISI 4130 steel should be carried out at around 600 deg C for a holding time of 1inch/ hour of material thickness.

A higher holding time can be kept but it must not decrease the tensile strength below its minimum specified limit.

Also, another important criterion for the selection of PWHT temperature is that the PWHT temperature must be kept below the tempering temperature of the material. as a high PWHT temperature will destroy the tempering effect in the base material.

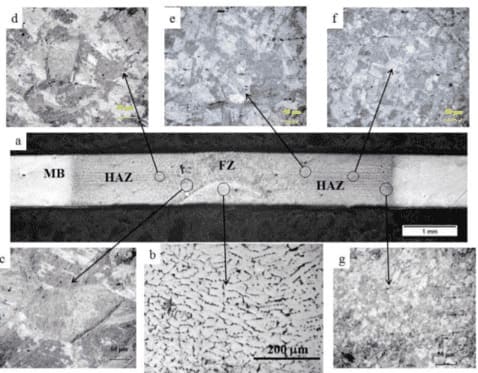

The below picture shows the microstructure obtained during TIG welding of AISI 4130 at various locations.