What is a Welding Bead or Weld Bead?

The Welding Bead or Weld Bead is produced by depositing the weld metal on a base material to make a weld joint or give a weld overlay deposit (e.g. hard facing, buttering, cladding, etc.).

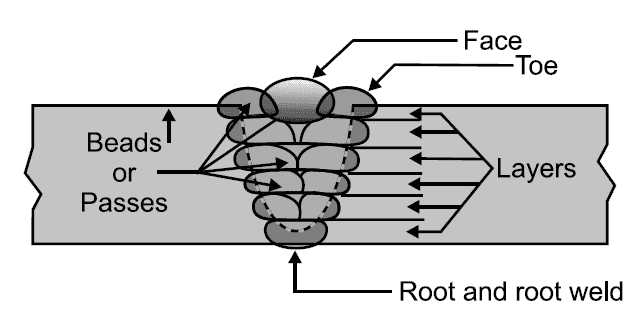

In the below joint you can see multiple weld beads deposited in a groove weld to form Welding layers. (Welding Layers are explained in this article later in detail).

The Weld bead & weld pass is two terminologies that are used interchangeably. A Weld Bead is a result of a deposited weld pass.

Where a Weld Pass can be defined as the single welding progression along a welding joint.

A Bead weld is a nonstandard definition used for surfacing weld.

Welding Bead Types

The main types of Welding Bead are:

- Stringer Bead

- Weaving Bead

- Whip Motion (Used in Stick Welding)

- Walking the Cup (Used in TIG Welding)

- Fill Bead

- Cover Bead

- Cosmetic Weld Bead or Smoothing Bead

- Back Bead/ Backing Bead

What is a Stringer bead weld?

A Stringer Bead Weld is a type of weld deposition technique performed by a welder without any welding rod weaving (cross weld axial movement).

In a Stringer Weld Bead, Welder welds straight weld passes without appreciable weaving motion.

Stringer Beads can be placed using the pull or push technique without using weaving motion.

As the weld beads are deposited in a straightforward path, Stringer Beads are very effective for welding in out-of-position welding (overhead, 6G position).

Benefits of Stringer Bead Weld

The Stringer Weld Bead takes place without appreciable weaving motion thus reducing the total time requires for each weld bead deposit.

This result in fast welding speed, low heat input, less distortion, lower residual stresses, and higher weld toughness (in the case of carbon steel material).

Stringer beads are very helpful when welding thin materials especially welding gauge sheets (Carbon steel, stainless steel, galvanized sheet, or aluminum). Although they are not beneficial for gap bridging.

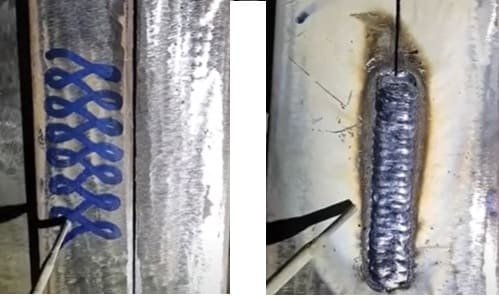

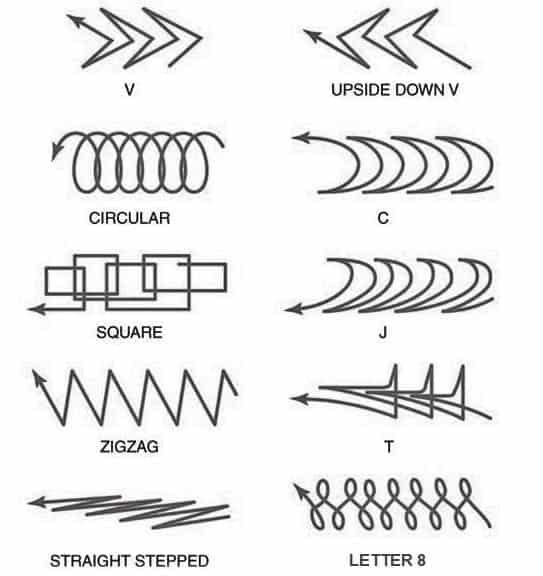

Weave bead welding

Weave Bead Welding is opposite to Stringer Bead Weld. In a Weave Bead Weld, the welder uses cross weld axial motion with a combination of weld torch & filler rod patterns, or also known as Weaving patterns as shown in the below sketch.

Stick/ TIG-MIG Welding Bead Patterns

Welder has their own choice for Weave Patterns where they have a mastery for producing high quality & appearance welds.

This pattern selection is crucial depending on Welding Position. For example, welding in the 1G position will not have many effects compared to welding uphill.

Along with filling the weld joint welder manipulate the welding torch/ welding rod in a predefined motion in weaving bead.

This provides the opportunity to fill the large gap, wider fill/cover passes, or increase heat input in welding to ensure good fusion.

Usually, a circular motion pattern is used for 1G (Flat Welding Position) in groove welds, fillet welds & Corner Welds as well as weld overlay applications.

For 3G welding or Vertical uphill, ‘C’ & ‘J’ patterns are good. ‘T’ Pattern is good for welding in overhead welding for fillet & Groove welds.

‘Letter 8’ and Zig-Zag Weaving patterns are useful for welding cover passes in 1G & 3G welding positions. Letter- 8, J & C Patterns allow welding heat built-up and this is good when welding thick plates.

Stringer Vs Weave Bead Welding

Stringer bead and Weave Bead are two different types of Welding Bead Placement Techniques offering their unique advantages & disadvantages.

Selection of these techniques is based on the welder choice, job requirements, material metallurgy concerns, or client specification needs.

Stringer Beads are helpful for welding thin materials, minimizing welding heat input, reducing welding distortion & residual stresses, promoting acicular ferrite in Carbon steel, austenite in stainless steel & phase balance in Duplex Stainless Steel. Stringer beads are good for welding cast iron repair works.

Weaving Bead on the other hand is good for gap bridging in open roots, welding fill & cover passes, and thick plates welding.

They provide high heat as a result of weaving motion, thus resulting in reduced welding speed and thus higher weld deposition rate.

MIG Welding Bead Patterns

MIG Welding Bead Patterns are ‘V-Pattern’, ‘Upside down V–Pattern’, ‘Circular -Pattern’, ‘C-Pattern’, ‘Square-Pattern’, ‘J-Pattern’, ZIGZAG-Pattern’, T–Pattern’, and Letter 8-Pattern’.

Above MIG Welding Bead Patterns are used by welder as per their choice. There are no minimum code or standard requirements for placing bead patterns and it is solely Welder’s Choice that suit them best.

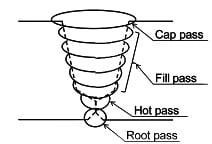

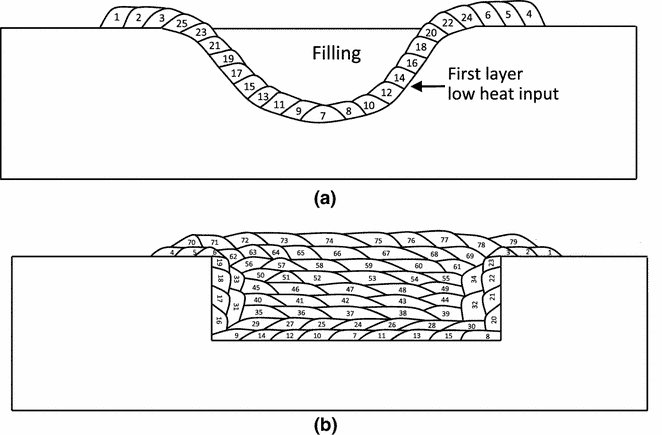

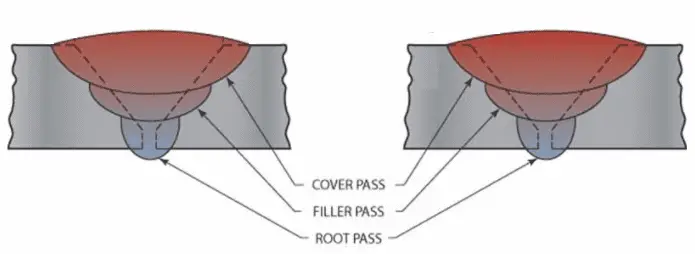

What is Welding Layer

A sequence of weld metal consisting of one or more weld passes/beads in a welding joint is called the Welding layer.

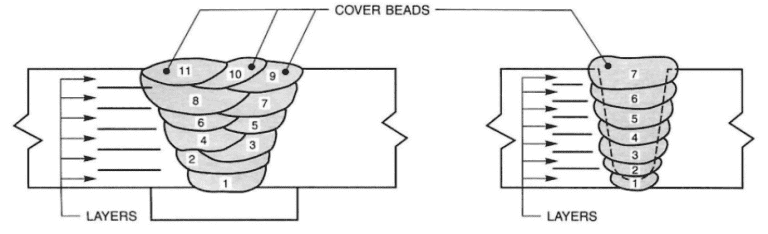

The layer may consist of one or more weld beads laid side by side as shown in the below figure.

As you will notice, the weld joint is welded in a number of passes which are the individual weld beads placed during the welding. Weld bead or weld pass is the same term.

The layers can have either a single weld bead or multiple weld beads placed within the same level in the welding joint.

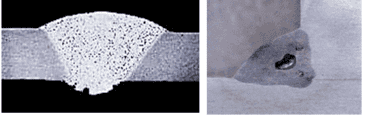

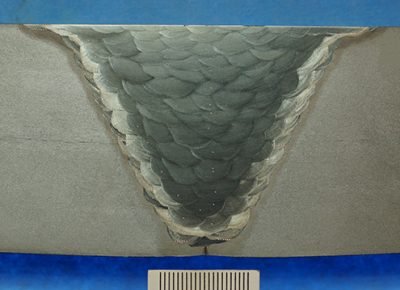

The weld macrograph of a single V joint given below shows that a number of weld beads are placed in the groove to fill the joint, but if we draw a number of layers, we can see that each layer consists of several numbers of weld beads or passes.

The root starts with one weld pass and nos. of passes per layer increases as the groove width increases. We can see that the final weld bead has the highest number of weld passes.

What is A Weld Bead or Pass

Weld bead or weld pass or weld run can be defined as the single progression of a welding or surfacing method along a welding joint, weld deposit, or on a base material. The result of a welding pass is a weld bead or weld layer.

As you will notice in the above picture, the Left-hand side, it contains multiple passes in each layer except the first and 2nd pass (only 1 weld bead in passes 1 & 2) while the picture on the right-hand side shows that each layer only contains single weld bead/ weld pass only.

So, a layer can have more than 1 pass but 1 pass is going to be a part of one layer only.

If we consider the principle of weld bead or weld, they can be defined as:

- Single-pass or single run weld

- Multipass weld or multi-run

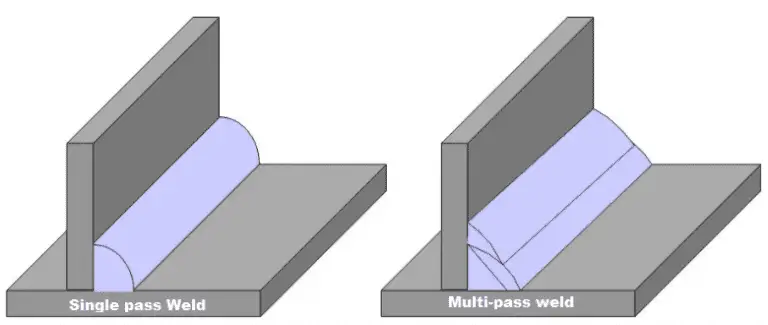

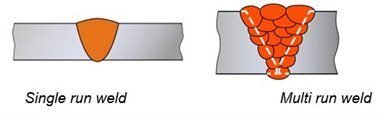

In a single pass or single run, only one weld bead is placed while in a multipass or multi-run weld, multiple weld beads are placed as shown in the below figure for a fillet weld joint.

In the left-hand side image, the fillet weld is welded using a single weld run, hence it’s a single pass weld.

While on the right-hand side image, the fillet weld is welded using 3 weld passes so it is a multipass weld.

The below example is given for single-pass/ single run and multipass/multi-run weld in a groove or butt weld joint.

What is the Capping Layer in Welding

The capping layer is a nonstandard term for the final layer of a groove/ butt weld joint. This is the weld pass/ passes which are visible on the surface of a final completed weld in a groove weld.

The top weld pass in the below picture forms the capping pass or capping bead or also called the cover pass in welding.

When we say capping layer, it will cover the number of passes in the final layer and can have either a single pass or multipass in the same layer.

What is Cover pass or cap pass in Welding

Weld pass (single pass weld) or welding passes deposited in layer & those are exposed to the surface from the side where welding was done, is called cover pass or capping run.

A weld bead resulting from a cover pass is called a cover bead or capping bead. An example of a cover passes in shown in the above picture.

What is Surfacing?

Surfacing is a welding technique used to weld deposit on the base metal surface (either similar metallurgy in case of material thickness loss, called weld built up or different metallurgy known as weld overlay or cladding for corrosion protection or hard facing etc.

Surfacing applications such as weld overlay, cladding and hard facing all are examples of Weld Surfacing.

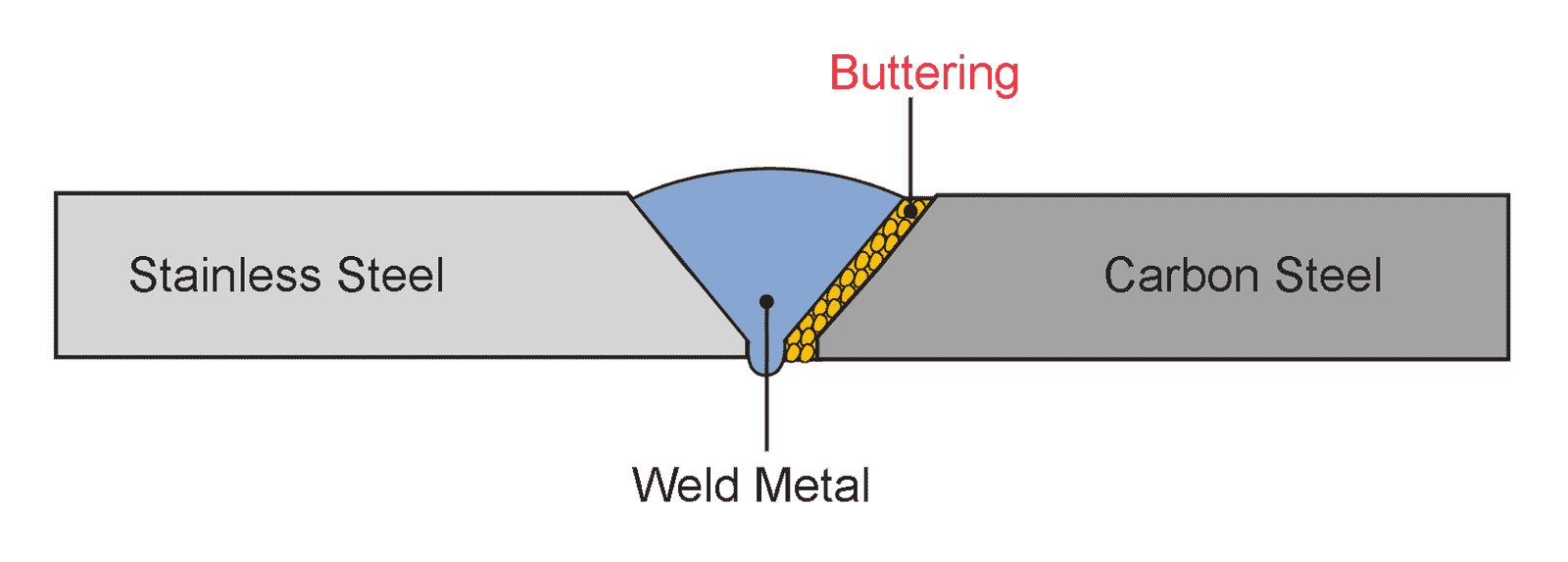

What is Weld Buttering?

Weld Buttering: Weld buttering is the process of depositing weld metal on a base metal to achieve dimensional tolerances.

E.g., Due to wrong weld face preparation or sometimes excessive material cutting, the weld face is buttered using the same metallurgy welding rod to restore the base material thickness.

Butting is also used for welding of dissimilar weld joints to avoid pwht. One case is, when welding Cr-Mo material to stainless steel, Cr-Mo material is buttered using SS309L filler wire followed by PWHT.

This buttered part is then welded to stainless steel to avoid PWHT of stainless steel material while for Cr-Mo where PWHT is mandatory is already carried out.

What is Weld Builtup?

Weld Built-up: Weld built-up is a type of surfacing method used to deposit similar metallurgy weld on components which has got material loss due to erosion or corrosion.

The term is widely used in oil & gas to perform weld deposits in vessels, columns, pump casting, etc.

Corrosion Resistance Overlay (CRO) and Hard-Facing Overlay (HFO)

What Does a Good Weld Bead Look Like?

Defining an aesthetic appearance is very difficult as each person perspective differs.

A Inspector who has dealt with, Let us assume fair quality welds only & he/ She has to inspect higher aesthetic welds than he dealt before- He will find them definitely of high quality.

But it is very important to know the minimum quality requirements before a Inspector perform the welding inspection. This will make his task easy & will provide a right inspection approach.

Sometime, a weld looks of high quality from outside but internally it will have lot of welding defects.

You will notice this for Aluminum MIG welds. Where external looks perfect but internally will have lot of welding porosity. As you can see in the below picture, weld is good from outside but internally has welding defects.