Cover Pass Welding Definition

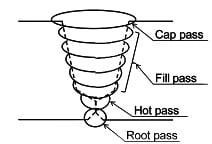

As the name suggests, Cover Pass Welding is the final weld pass in a welding joint. It’s very important for weld visual quality. The opposite of the root pass, the cover pass is also called the Cap pass or Capping run.

The main difference between the two passes is that the root pass (the first pass made when welding) must be taken first in order to fuse the metal at the bottom of the joint, while the cover pass fuses metal at the top of the joint.

In addition, the root pass provides most of the strength of a completed weld, while the cover pass provides cosmetic appeal and improves penetration into the base metal.

Importance of a Good Cover Pass

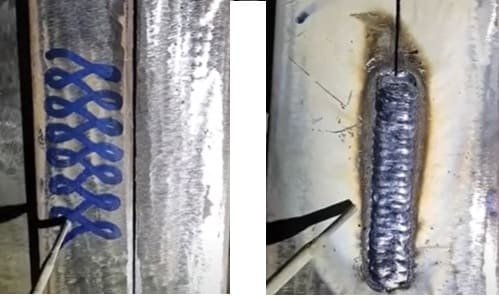

A good cover pass should have a uniform bead appearance with minimal spatter. It should be free of defects such as pores, cracks, incomplete fusion, or slag inclusions. The width and height of the bead should be within specified tolerances.

Welders use various techniques to produce a good cover pass.

One common technique is to use a smaller electrode than was used for the root pass to weld the Cap pass. This helps minimize spatter, good control of the weld bead placement, and provides better access to the weld joint.

Another technique is to use a higher welding current than was used for the root pass. This helps ensure complete fusion and prevents porosity, overlap, and other surface defects.

Types of Welding Passes

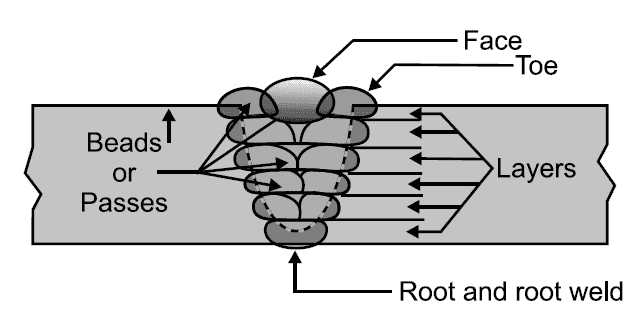

Welding passes are defined as the layers of welding that are deposited during a single welding process.

There are three types of welding passes:

- Root pass,

- Filling passes, and

- Cap or Cover Pass.

- The Root Pass is the first layer of welding deposited during a welding process. It is responsible for providing structural support to the weld joint and preventing the penetration of the weld metal into the base material.

- The Filling Pass is the second layer of welding deposited during a welding process. It is responsible for filling any voids left by the root pass and for increasing the strength of the weld joint. Depending on the material thickness, one weld joint can have a number of fill passes.

- The Cap or Cover Pass is the third and final layer of welding deposited during a welding process. It is responsible for protecting the weld joint from corrosion and providing a cosmetic finish to the weldment. The number of Cap Pass can be only one or multipass depending on the weld groove width.

What is Cap Weld?

Cap Weld is a welding term having different objectives and hence different meaning. In summary, there are two different meanings of Cap weld with their objective as listed below:

1. Cap Weld for welding of Cap on Pipes:

Cap weld is a type of welding that is used to attach a cap, or metal disk, to the end of a pipe.

This method is often used to seal off the end of a pipe that has been cut or damaged or to fabricate small-diameter vessels. The term Cap is used for small-diameter dish ends.

To weld a cap onto a pipe, first, the welder will clean the area around the end of the pipe. Next, they will place the cap over the end of the pipe and tack weld it in place.

Once the cap is secure, they will then weld around the circumference of the cap.

Cap welds are strong and durable, making them ideal for use in many industries, such as construction, manufacturing, and automotive repair.

2. Cap Weld term as a Weld pass

A Cap Weld is the final weld pass in a welding joint. It is also called a weld capping or cover pass.

The purpose of a cap weld is to protect the underlying weld from contamination and to improve the appearance of the finished joint.

A cap weld is typically made with the same filler material as the underlying weld, but it can also be made with a different filler material.

The size and shape of a cap weld are determined by the welding process and joint configuration. A cap weld can be made with either an automatic or semi-automatic welding machine.