What is Golden Joint in Piping?

Welding joints are very important. They are the places where the two pieces of metal are joined together. A good welding joint will create a strong weld that will not break or leak.

“A Golden Joint in Piping refers to the final weld joint when joining an existing pipeline spool to a new piping spool by Welding and it’s not possible to perform the hydro test of this pipe spool.”

Continue reading the post of in depth information…

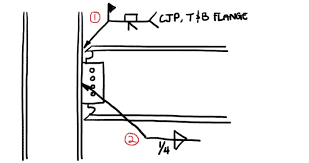

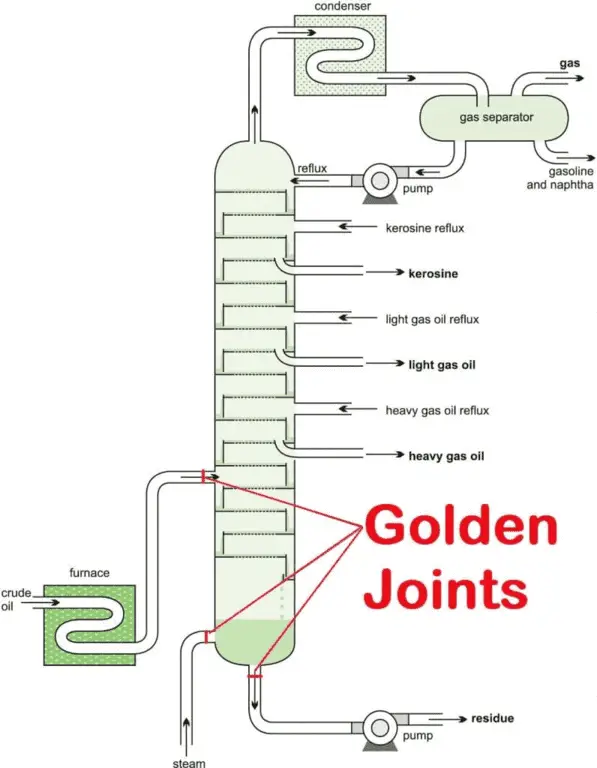

For example, a joint under the column, joining the column drain to further piping system as shown in the below diagram is not possible to perform the hydro test after welding due to the huge size of the column, so these joints will be Golden Joints.

To ensure to joint integrity, extensive 100% weld inspection is performed by using NDT such as radiographic testing, PT or MPI, and Visual Testing in place of Hydro Test or Pneumatic test.

This brings the extra cost to these specific joints, so the Joint is named as Golden Joint.

The golden joint is required if the location of the pipeline line is not possible to be hydro tested, so the client chooses several golden joints in several places that are estimated to be critical.

And the welding of the golden joint must be witnessed by the QC for root, fill with penetrant testing, and after full weld by performing radiography.

Practical Meaning of a Golden Joint

A “golden joint” refers to a weld joint that typically serves as the final connection between existing piping and new piping. Unlike other weld joints, the “golden joint” is not subjected to pressure testing. Instead, non-destructive examination (NDE) techniques are used to inspect the joint.

Due to the limitations of NDE compared to hydrostatic or pneumatic pressure testing, many owners prefer to assign only their most skilled welders to perform these joints. A “Golden weld” or “golden joint” refers to a weld that cannot undergo hydrostatic testing due to various reasons such as being the final weld on site or having refractory material behind it.

Consequently, this weld undergoes 100% NDT inspection using multiple techniques such as ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MT), liquid penetrant testing (PT), among others. The term “golden” is used to signify the significant cost associated with conducting multiple 100% NDT inspections.

What is a Closure Weld Joint in Piping?

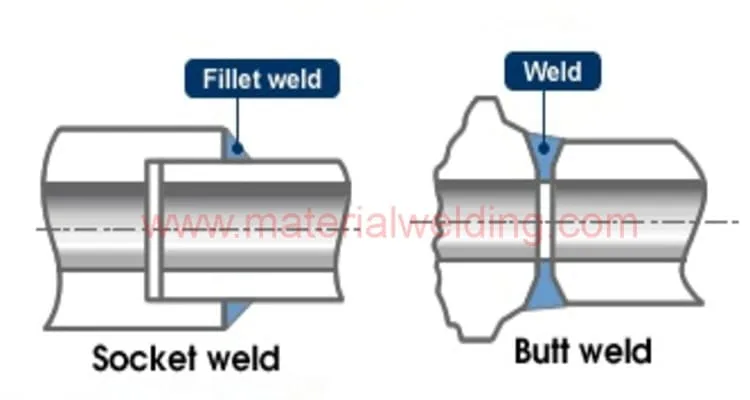

Closure weld joints are an important part of piping systems. Closure weld or also called final weld according to ASME B31.1 or B31.3 is used for joining a new pipe or existing pipeline spools to a new pipe or piping components such as a socket.

“One example of closure joint for example a pipe construction that started from two sides and then there is a final joint that is joining these two pipe spools.”

This is very common when laying cross-country pipelines. Other examples are quite often observed in running plants where an existing piping system is connected to a new system.

What is a Tie-in Joint in Piping?

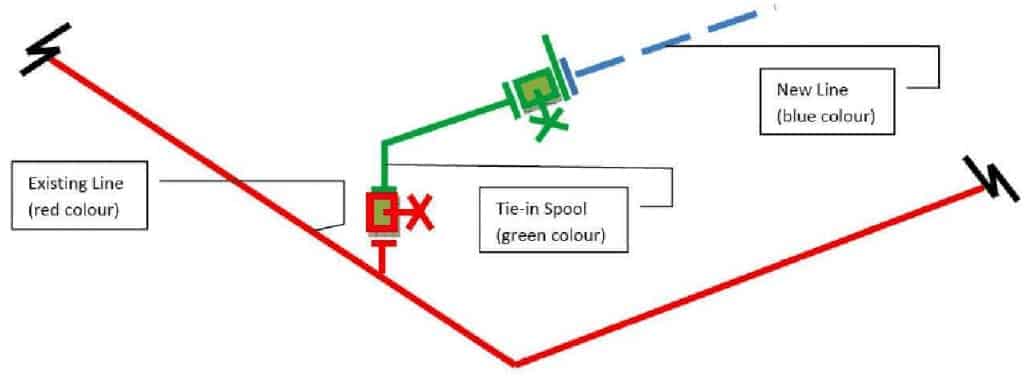

Tie-in joint means joining a new pipeline or branch connection to an existing line by fabrication (cutting & welding).

Tie-in joints are very common in refineries and power plants where extensive piping is used and it required Tie-in joints to accommodate modifications to the lines.

For example, in the below piping diagram, the red line represents an existing piping system, and a blue line is connected using a Tie-in joint.

Tie-in joints are used during plant expansion activities to connect existing lines to new lines and the point where this new joint will come is known as Tie-in Joint.

This Tie-in connection could be by inserting a new spool or installing a valve.

Piping Tie-in is very common in plants for compressed air lines, fluid lines, steam, or fuel gas process piping where using a Tie-in joint can increase the process efficiency or flow.

There are four types of Tie-in joints as given below:

- Existing line Tie-in

- Line Isolation type

- Shut down type

- Hot tapping type

The tie-in joint in piping is a connector between two lengths of pipe. It is used to create a permanent or temporary connection between the pipes.

The tie-in joint is also used to change the direction of the pipe. The joint is made up of two pieces of pipe that are welded or threaded together.

The tie-in joint should be leakproof and should have a minimum of resistance to flow.

Difference between tie-in and golden joint

The main difference between a Tie-in joint and a golden joint is the level of testing.

A golden joint is where the hydrostatic test is not possible as stated above while for the Tie-in joint, the hydro test can be performed thus no need to carry out extensive weld testing using NDT.

So, a Tie-in joint is cheaper than a Golden joint. Both Tie-in and golden joints are used to join an existing piping system to a new piping system but in Tie-in joint there can be a connection via a valve or some other components while in a Golden joint it will be between the pipes only.

Similar Posts: