What is a Lap Weld Joint?

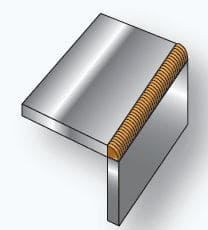

Lap joints are used for joining two overlapping plates so that the edge of each plate is welded to the surface of the other. The overlapping portion is called the LAP.

In a Lap joint, the width of the Lap is generally 3 to 5 times the thickness of the plate to be welded. Welds are usually run on each side of the Lap.

Lap weld joints are one of the most common and versatile types of welds. Lap welds are created by overlapping two pieces of metal and then welding them along their overlapping edges.

Lap welds are created by welding fillet weld (either continuous or stitch weld types) along the overlapping area of two members. They are designed for shear stresses mainly.

Lap Weld Symbol

There is no special symbol for lap welds as they are actually a type of weld joint and not a type of weld configuration.

A lap weld is a type of welding joint in which two pieces of metal are joined together by overlapping them and welding along the seam. The most common type of lap weld is the fillet weld, which is created by welding along the edge of the overlap.

Types of Lap Weld

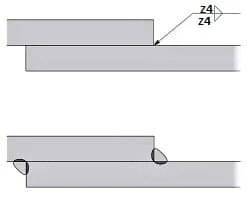

The main types of Lap Weld Joints are:

- Single Welde Lap Joint

- Double Welded Lap Joint

- Joggled or Offset Lap Joint

Lap Weld Joint Design

In Lap weld, the overlaps of joining members are usually from 30% to 80%. Lap joints should not be used on plate thickness above 10 mm or 1/2 inch approximately. In essential weldments lap joints must be welded from both sides.

Lap Weld vs Fillet Weld

Two of the most common types of welding are lap welds and fillet welds. So, what is the difference between these two types of welding?

Lap welds are created when two pieces of metal are placed on top of each other and then joined together using welding. This type of weld is often used for sheets of metal that will be exposed to high levels of stress, as it creates a very strong joint. However, lap welds can be difficult to create as they require a lot of precision.

Fillet welds, on the other hand, are created by welding two members at a right angle to each other. This type of weld is much easier to create than a lap weld, but it isn’t as strong.

Lap Weld Preparation

In order to create a strong and reliable lap weld, proper preparation is essential.

Before welding, the two pieces of metal to be joined must be cleaned of all dirt, grease, paint, or other contaminants. This can be done with a wire brush, sandpaper, or solvent cleaner.

Once the surfaces are clean, they should be positioned so that there is a small gap between them – this gap will allow for proper penetration during welding.

Proper alignment is also important for creating a strong lap weld. The two pieces of metal should be positioned so that they overlap by at least 1/2″. Once the pieces are properly aligned and positioned, welding can begin.

Lap Weld Applications

Lap weld joints are commonly used in the construction of both steel and aluminum structures. They are particularly well-suited for joining thin sheets of metal, as the lap provides good support for the weld pool.

When properly executed, lap welds can be very strong and have a high resistance to fatigue.

Lap Joint advantages and disadvantages

Lap joints are one of the most popular and commonly used methods for joining two pieces of metal together. There are many advantages to using lap joints, including their ease of assembly, strength, and versatility.

However, there are also some disadvantages to using lap joints that should be considered before deciding if they are the best option for your project.

One of the biggest advantages of lap joints is their ease of assembly. Lap joints can be assembled quickly and easily with minimal tools or training required. This makes them an ideal choice for projects where time is a factor, or for those who are not experienced in welding or fabricating.

Another advantage of lap joints is their strength. When properly welded, lap joints are very strong and can handle a lot of stress without failure.

The main disadvantage of Lap joints is that their load-bearing capacity is usually limited only to shear stress loading. Also, in a Lap weld, some metal is wasted on the lap.