What is the minimum distance between two welds?

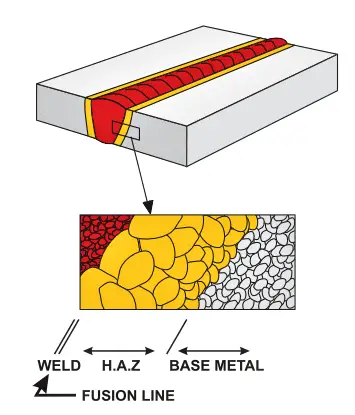

Welds should be placed at such a distance that the heat-affected zone (HAZ) does not overlap each other.

The overlapping of heat affected zone is acceptable as long as the effects on the heat-treated or hardened areas ( for example, residual stresses, reduction in strength, and decrease in hardness) are considered in the design.

This is the most common welding design-related issue faced by almost every Welding Engineer, Design Engineer, QA-QC Engineer & Welding inspector.

Many people try to co-relate it as overmatching HAZ, reduction in weld strength if welds seams are in close proximity. But does it all really a concern?

Let’s find out in this post.

Also, for structural parts, in order to reduce angular deformation and stress build-up, the minimum distance between two joints is determined according to the thickness of the parts joined and the clamping arrangement of the assembly.

What is the minimum Weld toe to toe distance?

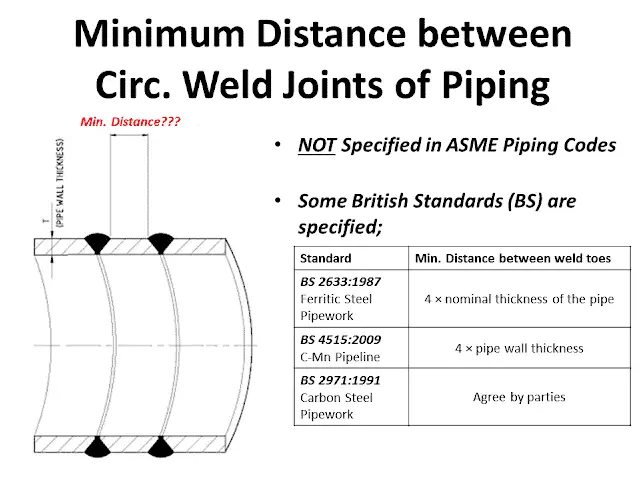

BS 4515 standard specifies the proximity between two welds shall be a minimum of 4X (4-times) of pipe wall thickness.

In API 650 & 653 the minimum weld toe to toe distance shall be 250 millimeters (10 inches).

Based on practical experiments, for thickness less than 20 millimeters (3/4 inch), and particularly for aluminum and high-strength steels, it is recommended to maintain HAZ at least 40 millimeters (2 inches) from each other.

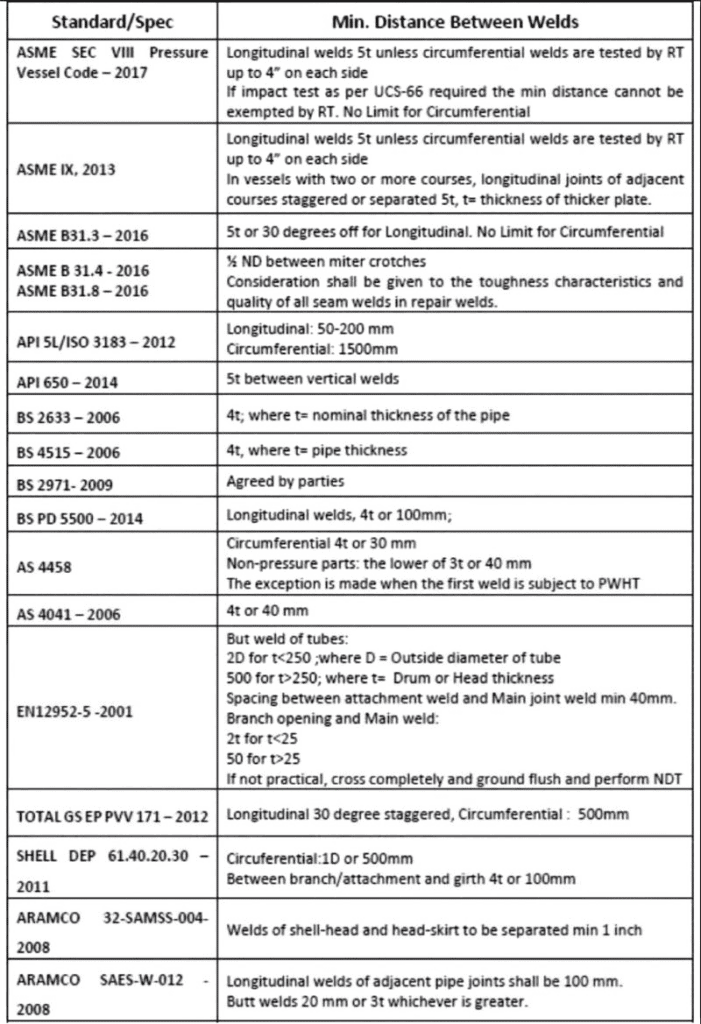

What is there in various codes & standards?

In API 1104, ASME B31.3, or ASME Section 8, there are no words about the distance between two weld seams.

Each weld qualified using a qualified Welding Procedure Qualification is supposed to offer minimum required mechanical properties such as tensile strength, yield strength, toughness, or hardness, etc.

Having multiple weld joints which meet the minimum specified inspection requirements, will not going to affect the integrity of the pipe joints.

So what can be the disadvantages of two close proximity seams?

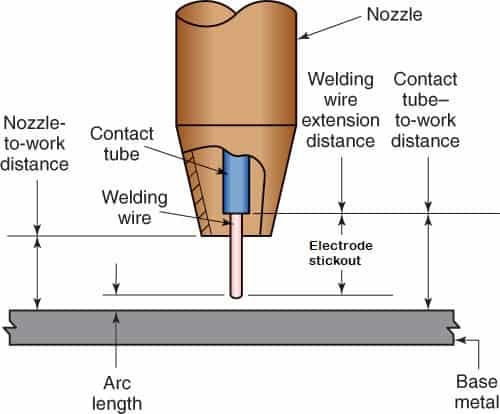

Obviously, too close welds seams will make the welding inspection more complicated. For example, having two circumferential seams in pipe joints will affect the root run and the internal inspection.

Close weld seams can hinder the full coverage of the root run, can mask or merge in a double-wall radiograph, or will not offer access for UT probing.

Minimum distance between two welds Standard Reference

EN 15085, which is a design standard for welding of railway vehicles provide an accurate reference to this.

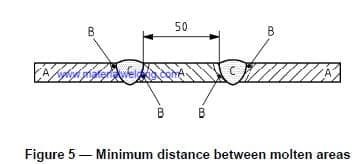

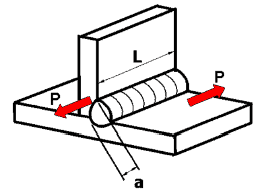

As per EN 15085-3, Clause 7.3.4 Proximity of two joints, states that the minimum distance between two heat affected zones shall be 50 mm (2 inches) for material thickness more than 20 mm. Refer below figure for reference.

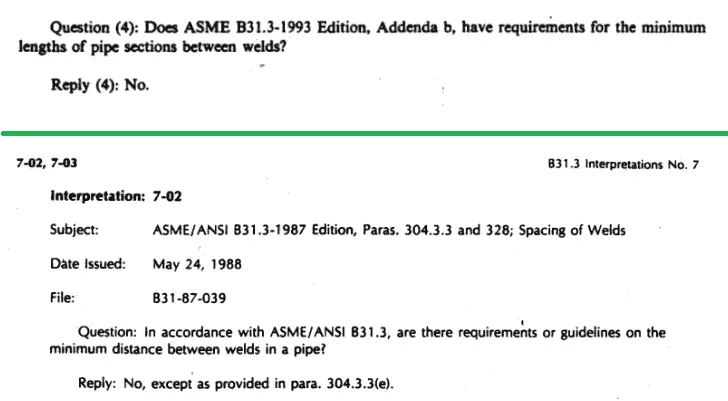

The minimum distance between two weld seams as per ASME B 31.3

To your disappointment, ASME B31.3 or ASME Section VIII has not given any such reference. Also, there is no such reference in AWS D1.1 Structural Welding Code.

ASME B31.3 is also clarified by the code interpretation No. 14-03(b) & No. 7-02 as:

Which standard cover minimum distance between two weld seams?

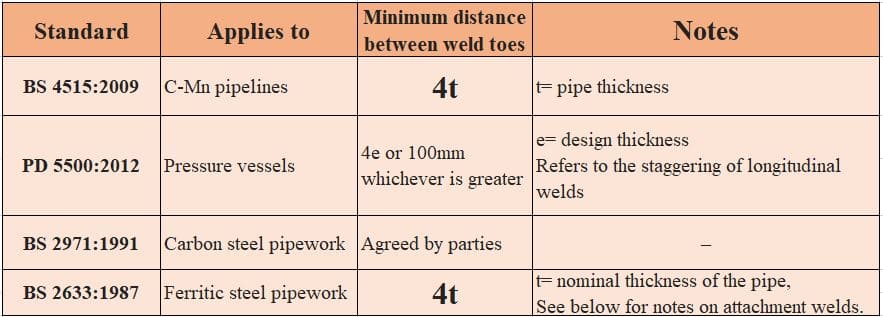

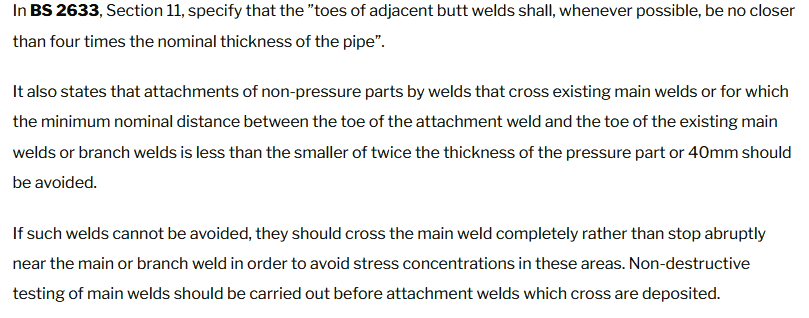

Well, for those who are looking for a standard reference to satisfy client queries, or to insert any such reference to the contractors, there is a relief for them in BS codes such as BS 4515-1(Carbon and carbon-manganese steel pipelines), BS 2633-1987, BS 2971-1991 & PD 5500:2012.

The table given below summarizes the requirements of these standards.

How do Two Close Weld Seams affect the Weld Joint Quality?

As discussed earlier, two close weld seams can have structural integrity as long as they don’t hinder the inspection of each other.

The most common misconception that two HAZ will overlap and lower the mechanical properties is totally out of scope when you are dealing with carbon steel or low alloy steel.

Practically, the new HAZ is going to create the tempering of the previous weld HAZ if they are really close. And, we know tempering does improve the mechanical properties of the weld not degrade them.

This can be a potential issue in the welding of super duplex stainless steel or modified low alloy steels, where such overlapping of the HAZ can change the phase balance or give rise to the grain growth in the microstructure.

In such cases, the weld joint integrity will be compromised due to decreased corrosion resistance or a decrease in mechanical properties.

Recommended distance between two weld seams

Most of the engineering specifications require a minimum 2-inch distance between two weld seams. Some specifications call for 2T, where T is the thickness of the pipe.

The rationale is the same as stated above, to allow proper inspections & avoid HAZ overlapping.

Based on practical experiments, for thickness less than 20 millimeters (3/4 inch), and particularly for aluminum and high-strength steels, it is recommended to maintain HAZ at least 40 millimeters (2 inches) from each other.

Minimum distance between Welds: ASME VIII

ASME VIII is the pressure vessel code for designing and building welded vessels. The minimum distance between two welds unfortunately not mentioned in ASME Section VIII.

As a good engineering practice, it is advised to keep a distance of 2 inch between 2 welds to avoid deterioration of mechanical properties that might occurs doe HAZ overlapping.

Thank you. very useful article for all engineers and inspectors.