Groove Design and Bevel Preparation for Welding

Weld preparation is a crucial step in creating strong and reliable connections through welding or brazing. The dimensions and angles involved in groove design and bevel preparation can vary depending on the Welding Procedure Specification (WPS).

In this article, we will explore the key aspects of groove design and bevel preparation, including the angle of bevel, root face, root gap, root radius, land, and the principles behind edge preparation.

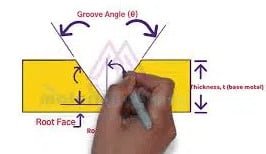

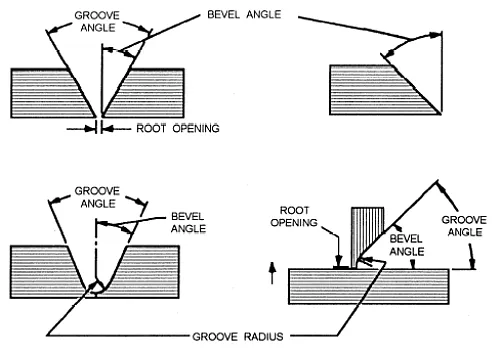

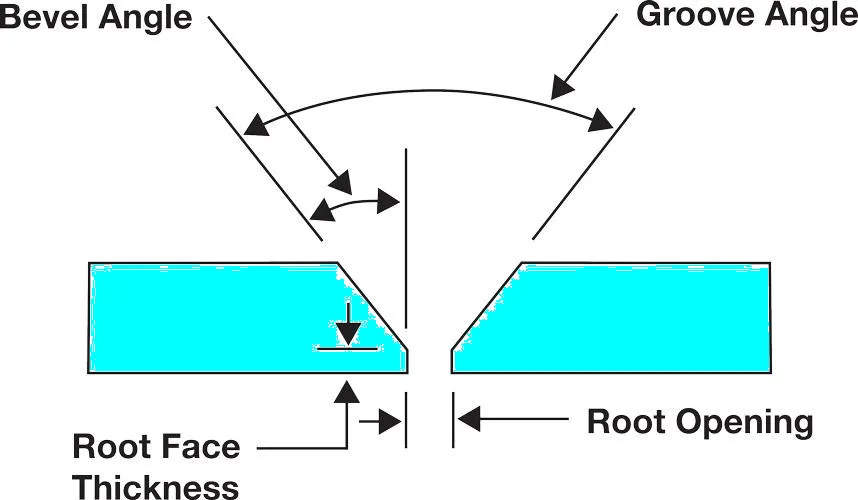

Angle of Bevel

Angle of Bevel: The angle of bevel refers to the edge preparation of a component for welding. The bevel angle is the angle formed between the prepared edge of a member and a plane perpendicular to the surface of the member.The typical angles for different types of preparations are as follows:

- V preparation: 25-30 degrees

- U preparation: 8-12 degrees

- Single bevel preparation: 40-50 degrees

- J preparation: 10-20 degrees in butt welding, 45-50 degrees in T-Joints.

It’s important to note that these values are for reference only, as the actual angle and groove type depend on factors such as the structure design, welding processes, and cost-saving considerations.

Groove Angle

The groove angle represents the combined angle of the groove formed between the parts that need to be connected. To illustrate, if the edges of two plates were inclined at 30 degrees each, the groove angle would amount to 60 degrees. This is commonly known as the “included angle” between the parts that will be joined through a groove weld.

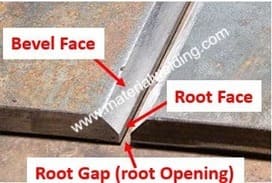

Root Face

Root Face: The root face is the portion of the fusion face at the root that is not beveled or grooved. Its value depends on the welding process used, parent material, and application. For full penetration welds on carbon steel plates, the root face typically has a value of 1-2mm.

Root Gap (Root Opening)

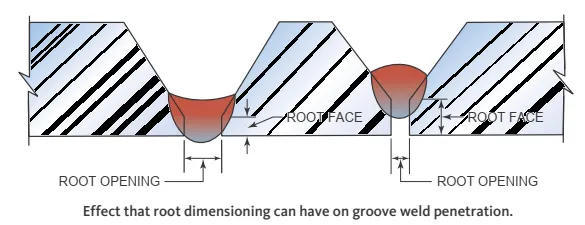

Root Gap (Root Opening): The root gap refers to the minimum distance between the edges or surfaces to be joined at any cross-section. Its value depends on the welding process and application. For full penetration welds on carbon steel plates, the root gap usually ranges between 1-4mm.

The root opening, also known as the root gap, is the distance or separation between the parts that are to be joined at the root of a joint. It is an important parameter in welding and is typically specified in welding procedures or standards. The root opening plays a crucial role in determining the quality and strength of the weld joint. It affects factors such as penetration, weld bead shape, and the amount of filler material required.

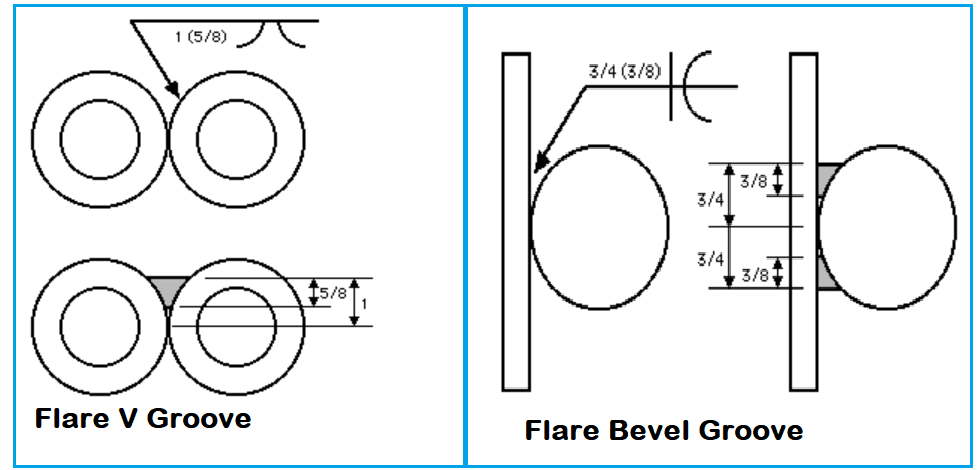

Root Radius

Root Radius: The root radius is the curved portion of the fusion face in a component prepared for a single J, single U, double J, or double U weld. In MMA, MIG/MAG, and oxyfuel gas welding on carbon steel plates, the root radius is typically 6mm for single and double U preparations and 8mm for single and double J preparations.

Groove Radius

The groove radius refers to the radius used to shape the J- or U-groove weld joint. It is typically used in special groove joint designs where a curved profile is desired. The groove radius helps to distribute stress and improve the strength and integrity of the weld joint.

By incorporating a radius, the joint becomes smoother, reducing the likelihood of stress concentration and potential failure points. This can be particularly important in applications where the joint will be subjected to significant loads or stress.

Land

Land: The land refers to the straight portion of the fusion face between the root face and the curved part of a J or U preparation. In some cases, the land can be zero, especially in weld preparations for MIG welding of aluminum alloys.

Weld Groove Designing guidelines

To determine the bevel angle, groove angle, and root opening for a joint, several factors must be taken into account, including the thickness of the weld material, the type of joint, and the welding process. Generally, gas welding requires a larger groove angle compared to manual metal-arc welding.

The size of the root opening is typically determined by the diameter of the filler material, which is influenced by the thickness of the base metal and the welding position. It is crucial to have an adequate root opening to ensure proper root penetration.

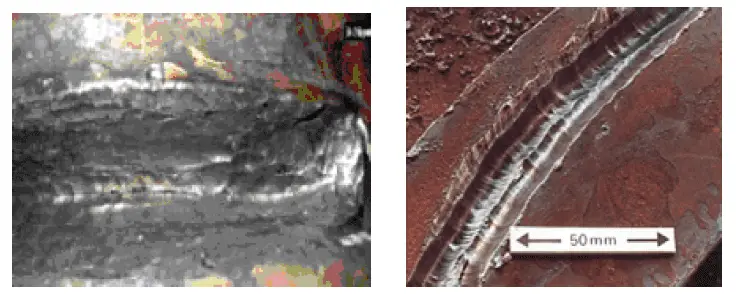

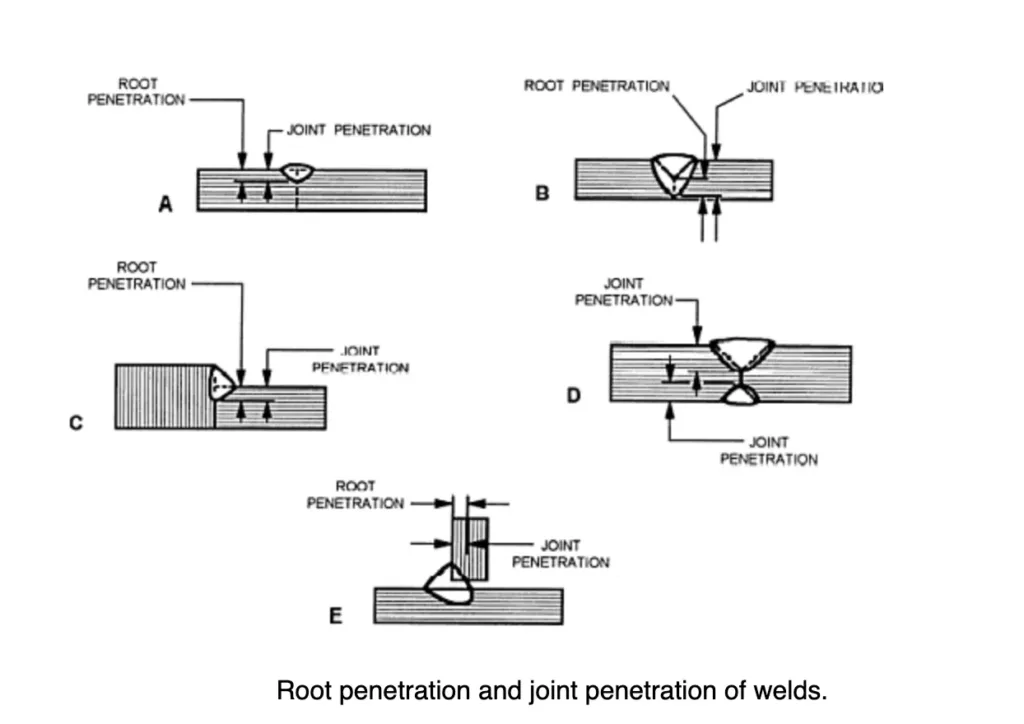

The figure below illustrates both root penetration and joint penetration of welds. Root penetration refers to the depth at which a weld extends into the root of the joint and is measured along the center line of the root cross section.

Joint penetration, on the other hand, refers to the minimum depth at which a groove or flange weld extends from its face into a joint, excluding any weld reinforcement. In some cases, the terms root penetration and joint penetration are used interchangeably, as seen in views A, C, and E of the illustration.

However, view B demonstrates the distinction between root penetration and joint penetration, while view D solely depicts joint penetration. Weld reinforcement refers to the excess weld metal beyond what is necessary to fill a joint.

Principles of Edge Preparation

Edge preparation plays a crucial role in increasing the strength of a weld. The area of the metal’s surface that is melted during the welding process is called the faying surface. By shaping the faying surface through edge preparation, the weld’s strength can be enhanced. Some key principles for preparing faying surfaces include:

- Codes and standards: Certain codes and standards may require specific edge preparations based on the welding application.

- Metals: Some metals, such as thick magnesium or cast iron, require specific edge preparations to ensure successful welding and minimize post-weld stress or cracking.

- Metal Thickness: As the metal thickness increases, joint design must be adjusted to ensure a sound weld. Thicker plates or pipes often require groove preparations such as bevel, V-groove, J-groove, or U-groove.

- Deeper Weld Penetration: Grooving or beveling the metal’s edge allows for easier fusion of the molten weld metal through the joint, enabling deeper weld penetration and potentially making through-thickness welds.

- Smooth Appearance: Grinding the weld’s surface smooth with the base metal can improve appearance and prevent interference with the sliding or moving of parts along the surface.

- Increased Strength: A weld should be as strong as or stronger than the base metal. Achieving 100% joint fusion and appropriate weld reinforcement ensures the weld meets its strength requirements.

- Welding Position: The flat position is often the most ideal for welding, as it allows for larger molten weld pools to be controlled. However, different groove designs may work better for out-of-position welding.

Conclusion

Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. The angle of bevel, root face, root gap, root radius, land, and principles of edge preparation all contribute to the overall quality and strength of a weld. By following proper groove design and bevel preparation techniques, welders can ensure the integrity of their welded connections.