Annealing vs. Normalizing

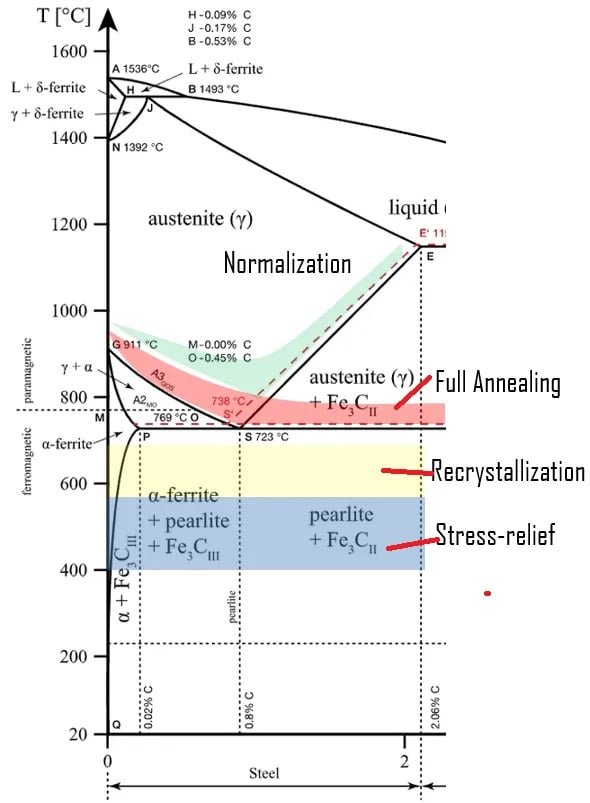

Annealing is a heat treatment process of heating the steels about 100°F (approx. 55° C) above the upper critical temperature (A3 line) and lower critical temperature (A3,1 line) as shown in the below Fe-C diagram.

Annealing is a Heat treatment, consisting of heating a material to a certain temperature, holding it at that temperature, and cooling in such a manner that the material is closer to equilibrium at room temperature.

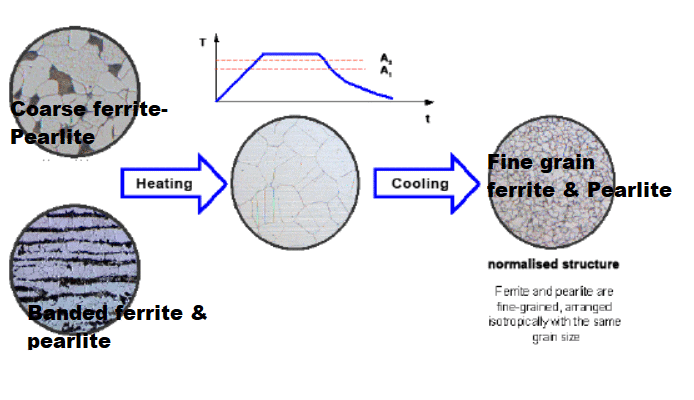

Normalizing is a method of heat treatment in which a steel, in whatever condition is reheated to a temperature exceeding the upper limit of the critical range (i.e., above A3 point) and cooled freely in air.

Normalizing means heating a steel to a temperature of about 55° C above the AC1, i.e., above the upper critical line of the iron-iron carbide phase diagram followed by cooling in still or lightly agitated air.

What is Normalizing?

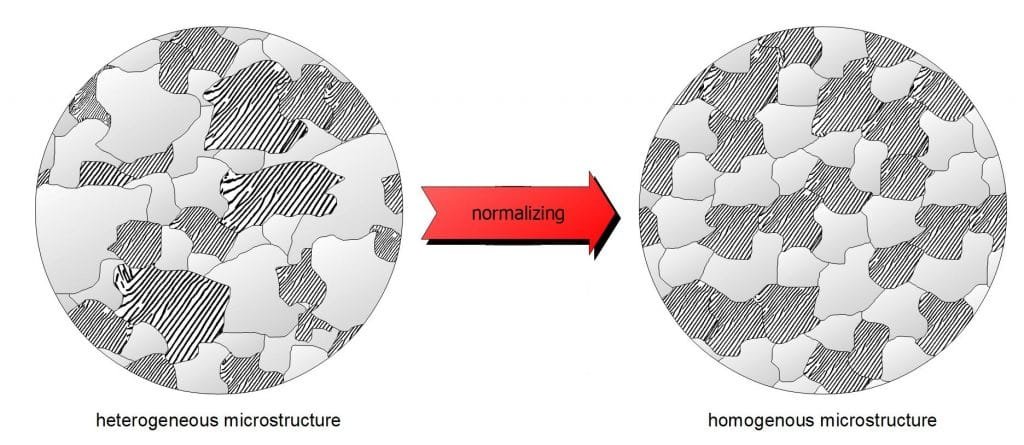

Normalizing is done for various reasons including grain-structure refinement, homogenization, removal of residual stresses and improved machinability.

Normalizing is a heat treatment process by which steels are heated nearly 100°F above the upper critical temperature (A3 or Acm line). hypo-eutectoid steels (steel less than 0.8% carbon) are heated to a temperature of 30°C to 50°C above the AC3 line and hypo-eutectoid steels are heated to a temperature of 30°C to 50°C above the AC1 line (723°C).

The temperature at AC3 line depends as it varies based on the carbon percentage in the alloy while AC1 temperature is constant.

A temperature equilibrium is brought to the part by holding it at certain temperature to have the uniform temperature throughout the part thickness, this is called dwell time.

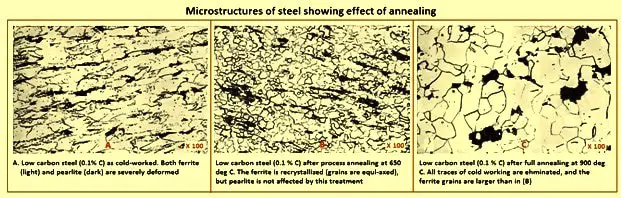

After that, it will be cooled in resting air. Because the steel is twice subjected to a y-α transformation, the material will be transformed into a uniform, fine-grained normal microstructure.

The purpose of the normalizing is also to obtain a uniform microstructure with fine lamellar pearlite in the material.

Cooling Medium in Heat Treatment

Cooling medium is one of the most important factors in heat treatment. The choice of cooling medium can affect the quality and properties of the product.

There are many different cooling media available, each with its own advantages and disadvantages. Some of the most common cooling media are water, oil, and air.

The cooling method used in the Annealing is furnace cooling at a moderate cooling rate which means the parts are cooled inside the furnace in a controlled atmosphere and not in the natural air.

Opposite of annealing is applicable for cooling in the Normalizing where parts are subjected to ambient air cooling & the cooling rates are not controlled.

The rate of air cooling in normalizing is much faster than the controlled furnace cooling that is applied in annealing heat treatment. The overall cost of Normalizing is lesser than the annealing process as the former does not require any controlled air cooling as mandatory in annealing.

Water is a very effective cooling medium. Oil is expensive than water but it is not as effective at transferring heat away from the product.

Air is inexpensive and easy to use, but it does not transfer heat as effectively as water or oil. Solid materials are inexpensive and can be used in large quantities, but they are not very effective at transferring heat away from the product.

Material Properties post the heat treatment

The heat treatment process can change the material’s properties in a number of ways.

The most common changes are: increasing or decreasing the hardness, ductility, and toughness. In general, the harder the material is, the less ductile it will be and the tougher it will be.

Conversely, softer materials are generally more ductile and tougher. The changes in material properties depend on the type of heat treatment process used, as well as on the composition and microstructure of the material.

Annealing vs Normalizing differences are given in the below table.

| Annealing specimen | Normalized specimen |

| Lower hardness reduced tensile and improved toughness. | Increased hardness, higher tensile than annealing, reduced toughness compared to annealing. |

| Uniform grain size after normalizing | Less uniform grain size |

| Less internal stresses | higher internal stresses compare to normalizing |

| Coarse microstructure | Fine microstructure |

Purpose of Annealing and Normalizing

Annealing and normalizing are two different processes that are often confused.

Annealing is the process of heating metal to a certain temperature and then slowly cooling it back down to room temperature. This process makes the metal more flexible and easier to work with.

Normalizing is the process of heating metal to a certain temperature and then cooling faster than annealing it back down to room temperature.

| Annealing | Normalizing |

| 1. To refine the crystalline structure and 2. To remove the residual stresses 3. To increase material ductility by minimizing the hardness and brittleness | 1. To achieve a refined grain structure before hardening. 2. To minimize the segregation in the casting or forgings. 3. To harden the steel minimally. |

Cost comparison between Annealing and Normalizing

The decision to anneal or normalize metal can be a difficult one. The cost of heat treatment should always be considered when making this decision. Annealing and normalizing are two types of heat treatments that are often used to improve the mechanical properties of metals. Both annealing and normalizing are performed at high temperatures, but they achieve different results.

The cost of annealing depends on the size and type of furnace required, as well as the fuel costs. Normalizing is a simpler process than annealing, so it typically costs less to perform.

Annealing: Annealing heat treatment is more expensive compared to normalizing. The reason is high controlled heating & cooling involved in annealing process which increase the heat treatment time.

Normalizing: Normalizing is less expensive compared to annealing.

Difference between Annealing and Tempering

Annealing is a heat treatment process that softens the metal. It is a form of thermal treatment in which the metal is heated to a temperature below the recrystallization temperature and then cooled slowly.

This procedure allows the dislocations in the metal to move and reorganize into a more stable arrangement. Annealing also increases the toughness and ductility of the metal.

Tempering is a heat treatment process that improves the mechanical properties of steel by decreasing its brittleness.

The tempering process usually involves heating the steel to a temperature above the critical point and then cooling it in air, oil, or water. Tempering increases the toughness, strength, and hardness of steel while reducing its ductility and susceptibility to fractures.

Difference between Annealing and Hardening (Quenching)

There are many types of heat treatments that can be applied to metals, but two of the most common are annealing and hardening.

Both processes serve to alter the metal’s microstructure and improve its mechanical properties, but they achieve this in different ways.

Annealing involves heating the metal to a relatively low temperature and then allowing it to cool slowly, while hardening involves heating the metal to a much higher temperature and then quenching it in water or oil.

The main difference between annealing and hardening is that annealing results in a softer metal, while hardening produces a harder metal. This is because annealing relaxes the internal stresses in the metal caused by cold working or casting, whereas hardening causes these stresses to become locked into place.

Difference between Annealing and Aging

Annealing and aging are two processes that are often confused. Annealing is a process of heating and then cooling metal to make it softer. Aging is a process of leaving metal in a hot environment for an extended period of time.

The difference between the two processes is that annealing makes metal softer, while aging makes metal harder.

Similar Posts: