Electrodes for TIG Welding

Grinding and preparing tungsten electrodes prior to welding is the key to a quality weld, stable arc, and uniform weld bead appearance. A wrong tungsten preparation for a welder can lead to shabby welds, wandering arc, and in-sufficient weld penetration.

This post guide the welders on how to prepare the tungsten for best welding outcomes. Before, let us see basic about Tungsten Electrode used in Welding.

TIG welding electrodes are made from Tungsten (either pure or by doping with other elements). The reason for using Tungsten is- it’s a high melting temperature of 3422°C (6192°F), thus is the best material for TIG electrodes that can give longer life.

The above melting temperature can be further increased by alloying the tungsten with other metals oxides (e.g. thorium oxide). This is called doping. Doping of tungsten electrodes increase its melting temperature, its electrical conductivity & reduced electric resistance, and improves arc ignition properties compared to pure tungsten electrode.

Why it’s important to Grind/ Sharpen Tungsten Electrodes in TIG Welding?

The correct distribution of energy in the direction of the parts to be welded and the magnitude of the arc pressure depend on the shape of the tip, which, in turn, will determine the shape of the weld.

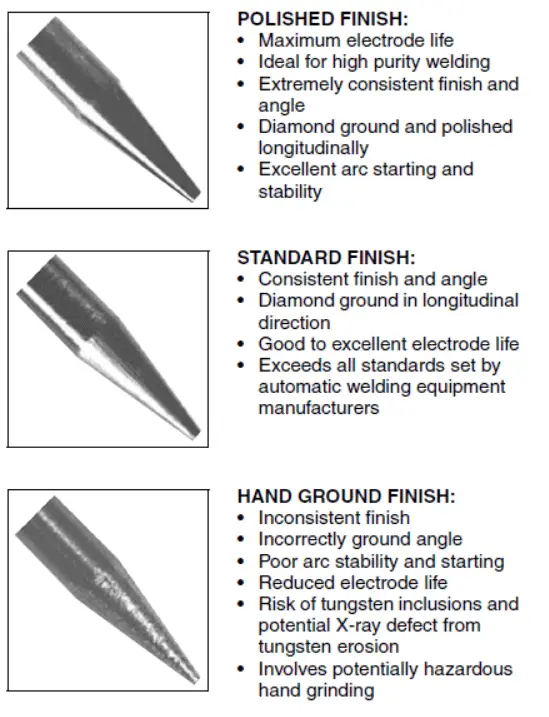

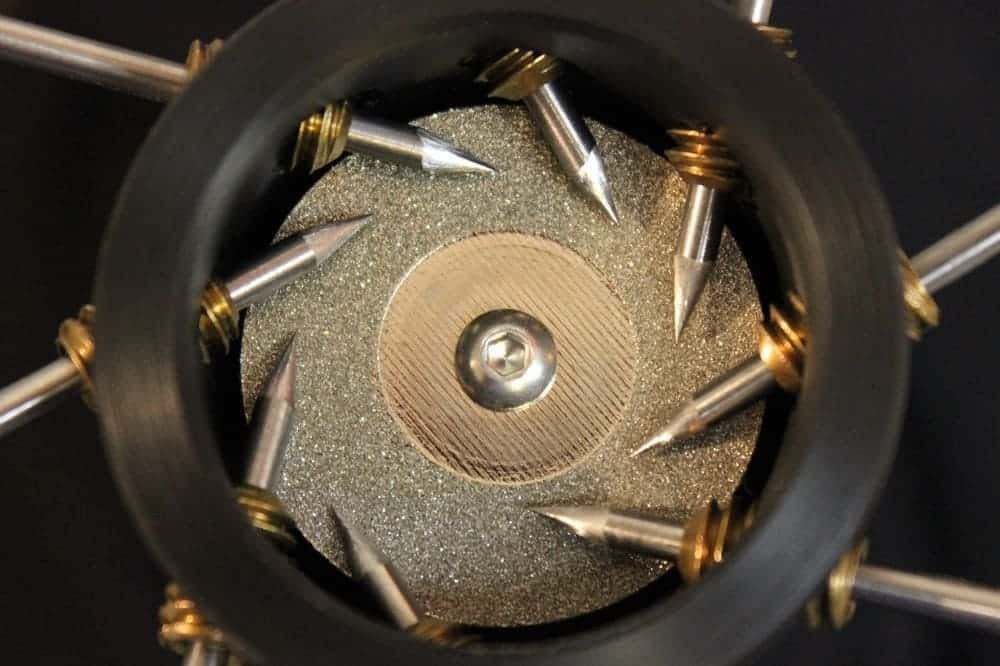

Therefore, sharpening must be approached seriously and competently. Sharpening can be carried out on an electric emery manually, but the best results are achieved using special devices, such as automatic tungsten grinders.

The shape of sharpening is determined by the brand of the electrode and the parameters of the workpieces to be welded:

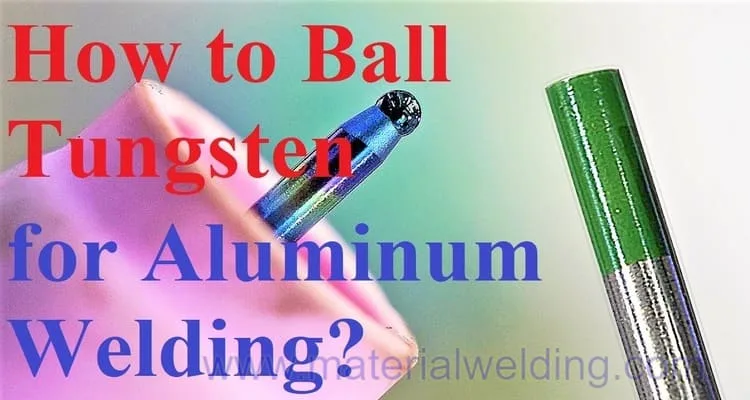

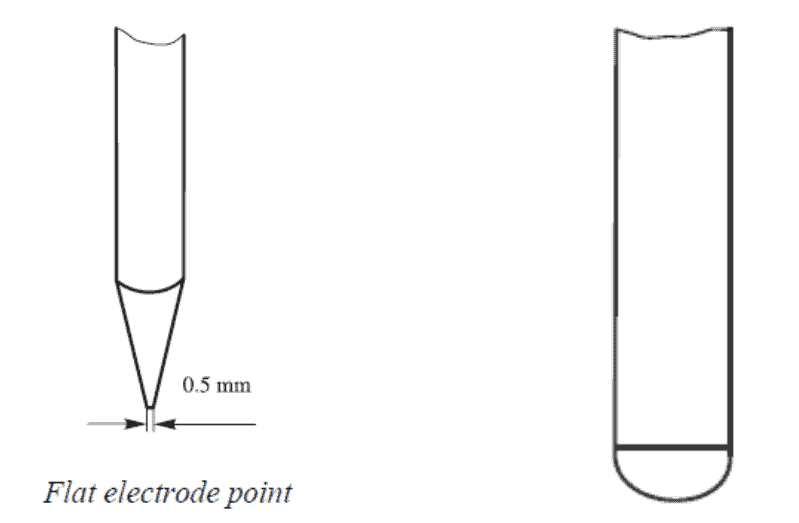

- Pure Tungsten electrode must end with a ball;

- Thoriated tungsten electrodes , the end of the electrode should have a slight bulge;

- Other types are sharpened with a cone (like a pencil).

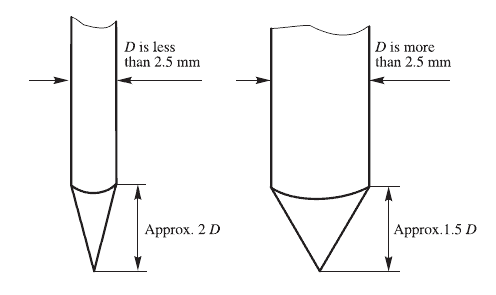

An interesting feature is observed when welding aluminum parts – a sphere is formed at the end of the electrode, and there is no need for sharpening. The length of the section to be sharpened is determined by the diameter of the bar multiplied by 2.5. This ratio is constant.

GET BEST PRICE FOR TUNGSTEN GRINDER

Check out these best available tungsten electrode grinders.

Details about various types of Tungsten electrodes used for TIG welding are given in AWS A5.12- SPECIFICATION FOR TUNGSTEN AND OXIDE DISPERSED TUNGSTEN ELECTRODES FOR ARC WELDING AND CUTTING.

The commonly used metal oxides for alloying of tungsten electrodes in TIG welding are:

• Thorium oxide (ThO2)

• Zirconium oxide (ZrO2)

• Lanthanum oxide (LaO2)

• Cerium oxide (CeO2)

Tungsten Electrodes dimensions & sizes

Tungsten electrodes are available in different diameters from 0.010 inches to 0.250 (1⁄4) inches (0.5 to 8 mm) for TIG welding. The most frequently used dimensions for TIG welding electrodes are 3⁄32 inches (2.4 mm) and 1⁄8 inches (3.2 mm). The selection of electrode diameter is based on the welding current, material to be welded, and type of current (AC or DC).

Grind correctly Tungsten for TIG Welding

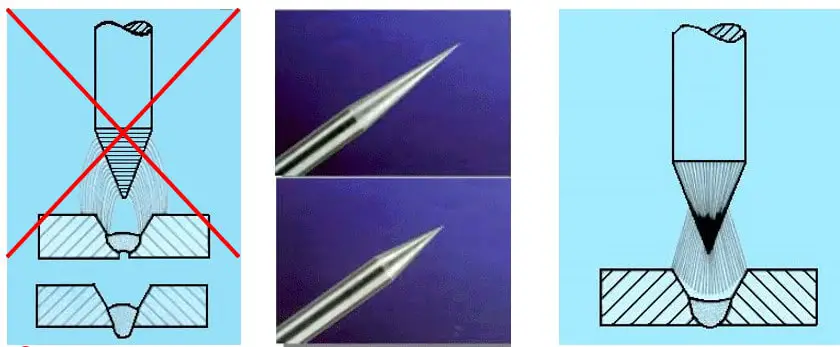

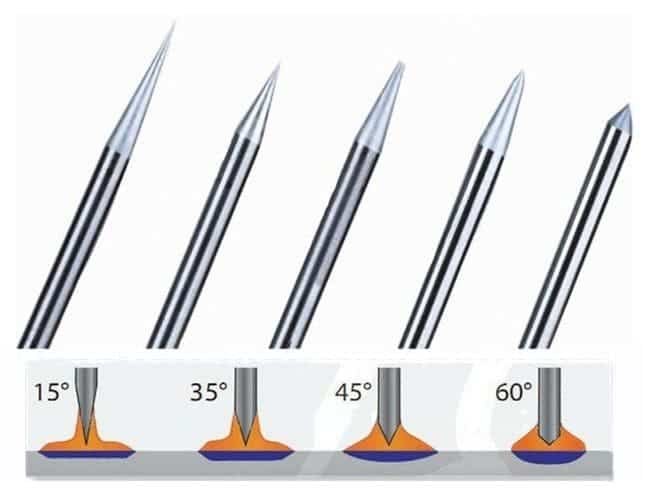

The most important condition for getting a good quality result of TIG welding is that the tungsten electrode point must be ground correctly to the shape. The angle of tungsten defines the shape of the weld pool- a small pointed rod angle will give a narrow weld pool while a rod with a bigger pointed angle will result in a wide weld pool.

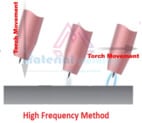

For DCEN welding polarity, the tungsten electrode should have a conical shape as shown in the below figure. This shape gives a concentrated/ focused welding arc which in turn gives a narrow and deeper welding penetration. As a thumb rule, the length of the ground conical shape shall be twice the diameter of the tungsten electrode. Refer the below picture on the right-hand side for more details.

Best techniques to grind a tungsten electrode

Follow these tips for the best tungsten rod grinding techniques for the best welding result.

- Blunt or un-sharpening the tungsten electrode point by making it flat for about 0.5 mm can enhance the life of the tungsten significantly.

- Tungsten electrodes for welding aluminum shall be rounded as during welding it carries a lot of currents.

- During grinding the tungsten, its point must be kept in the rotation direction of the grinding wheel. This will minimize the arc wandering issue. The grinding must be done in the axial direction and not in the radial direction.

- If possible, use the dedicated grinding machines. Using the grinder for other applications can damage the grinding disc.

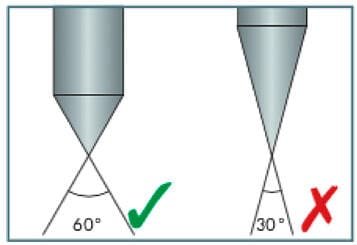

- Grind the tungsten to an angle of about 60 degrees for longer life.

- Use a tungsten grinding clamp. This will gives a tight grip on the rod while grinding. It will also be a safe work practice.

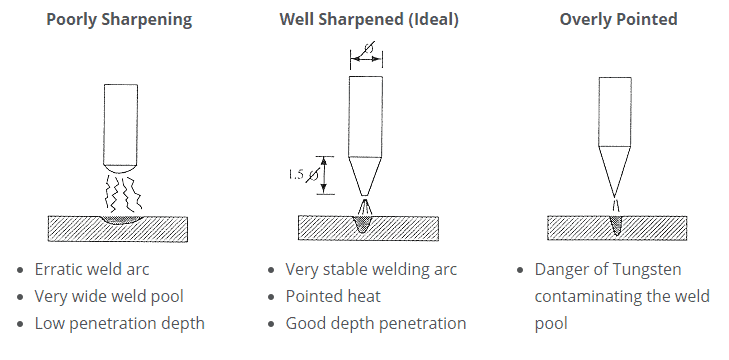

Effect of wrong ground tungsten in welding

In below picture is a more clear illustration of how the wrong grinding or sharpening of the tungsten electrode influences the welding performances:

Tungsten grinders machines (Tungsten electrode sharpener)

A Tungsten grinder (Tungsten electrode sharpener) is a device used to prepare tungsten for TIG welding using automated grinding arrangement. Portable tungsten grinders offers safety, choice for precise tungsten tip angle, wider adjusting option for tungsten preparation and time saving. You can purchase different type of tungsten directly from amazon at cheap rate. Refer the link above.

Similar Posts:

- What Color is Tungsten? Get the Answer Here by Chart!

- Shielding gases for MIG-MAG, TIG, and FCAW welding and shielding gases purity

- Types of Tungsten Welding Electrodes, their selection, color coding of tungsten electrodes & properties

- How to weld Aluminum with TIG, MIG & stick Welding?

- ER4043 TIG-MIG Welding Wire: Specification, properties, Uses